Article Archive

Article Archive

- Introduction of Cement Slurry System (Part 1)

- Introduction of Cement Slurry System (Part 2)

- Introduction of Cement Slurry System (Part 3)

- Introduction of Cement Slurry System (Part 4)

- High Temperature and High Pressure Cementing Technology

- Low Density Cementing Slurry Technology

- Anti Gas Channeling Cementing Technology

- Drag Reducing Agents (DRA) or Drag Reducers (DR)

- Nitrogen Surfactant Compound Huff and Puff Technology

- Oil Washing Technology for Increasing Production

4. Introduction to injection device

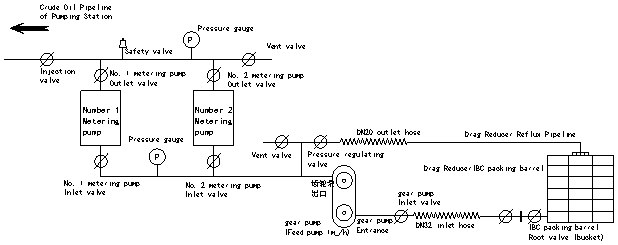

The drag reducing agent injection device introduced here uses an injection system developed by Zoranoc. The equipment uses a 1m³/h gear pump as the feed pump and two metering pumps. The device has the advantages of small size, low maintenance cost, convenient maintenance, etc., and is the most suitable dosing device for adding drugs such as drag reducing agents to suspensions.

Flow chart(You can also read Appendix II)

5. Pre test work

1.1 According to the actual situation on site, the injection point of drag reducer shall be determined at the proper position of the outgoing pipe section after the pump outlet, and the injection point shall avoid the valve and elbow as far as possible. Install and debug the drag reducer injection system and its related instruments. After the injection point, it is not allowed to pass through the needle valve, filter and other equipment that can shear the drag reducer. According to the actual situation on site, the injection point of drag reducer shall be determined at the proper position of the outgoing pipe section after the pump outlet, and the injection point shall avoid the valve and elbow as much as possible. Install and debug the drag reducer injection system and its related instruments. After the injection point, it is not allowed to pass through the needle valve, filter and other equipment that can shear the drag reducer.

1.2 Ensure sufficient diesel is available for testing during the test.

1.3 Carry out overall inspection and calibration for monitoring instruments, mainly including flow meter, thermometer and pressure gauge. All measuring instruments shall be calibrated with standard instruments and meters before test.

.jpg)