Article Archive

Article Archive

- Introduction of Cement Slurry System (Part 1)

- Introduction of Cement Slurry System (Part 2)

- Introduction of Cement Slurry System (Part 3)

- Introduction of Cement Slurry System (Part 4)

- High Temperature and High Pressure Cementing Technology

- Low Density Cementing Slurry Technology

- Anti Gas Channeling Cementing Technology

- Drag Reducing Agents (DRA) or Drag Reducers (DR)

- Nitrogen Surfactant Compound Huff and Puff Technology

- Oil Washing Technology for Increasing Production

Abstract: Drilling fluid technology, as essential completing technology for petroleum engineering, after a century’s development, it has been developing from the initial natural dispersion system to now a various chemical systems with a number of technical features and extreme cases (such as abnormal high temperature, abnormal high pressure) processing capacity, and wellbore stability technology has been the core factor that impacts the development and changes of drilling fluid technology. Research and development of new materials and technology have always been impacted by maintenance or improvement of wellbore stability, such a basic element. The studies around the demand of wellbore stability mostly concentrate in research on impacts of drilling fluid system, craft materials, balance of stress technologies and energy change to wellbore stability. With the continuous deepening of the combining degree of drilling technology and computer technology and other industrial technologies (such as nanotechnology), the drilling fluid technology presents some trends of changes, and new technical ideas of stressing the integrity of the balance in site operations also begins to show up, in order to promote the rapid development of China’s drilling fluid technology.

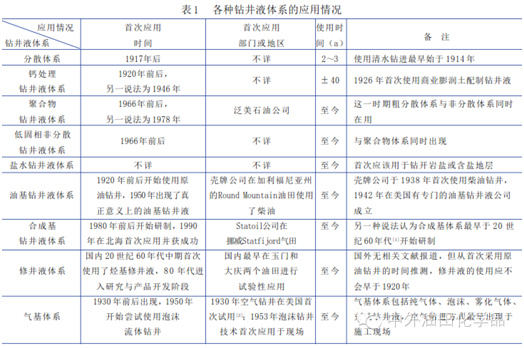

The development of drilling fluid technology is inseparable with the technical requirements of drilling engineering, and it has been a century from making drilling mud in a natural way in the early 20th century to today’s wide application of the specialized and versatile drilling fluid (see Table 1 for application of a variety of drilling fluid systems), and during this time, drilling techniques and materials has been developing continuously. But due to the limitations of theory and methods (or even thinking), its development process may not be smooth, and the factors for technological revolution are accumulating, but where the final breaking point would be now seems still confusing.

As we can see from Table 1 the three characteristics, first, special drilling fluids used in a specific environment, such as air base, foam, salt fluid, etc., have been applied today since their appearance. Second, the stable-effect and simple-operation systems have been in use by now, such as oil-based drilling fluids. Third, the systems with continuous technological heritage, such as polymers and their derivative systems, by the current development situation, due to the support from the factors of new materials development, it may be the most vital area.

Essentially, drilling fluid has two functions: First, to maintain wellbore stability to ensure that the geometry changes in upper openhole section will not affect the normal drilling operations before reaching designed depth; Second, to timely and efficiently carry the drill cuttings to the ground, in order to keep wellbore clean. All the other functions are derivative or additional of the drilling fluid. From the nature of drilling engineering, to keep the borehole stale is the first one, and without this foundation, all technical parts related with drilling engineering are out of the question. Therefore, technology exploration around the needs of wellbore stability has never stopped; the studies mostly concentrate in research on impacts of drilling fluid system, craft materials, balance of stress technologies and energy change to wellbore stability.

1. Research of drilling fluid systems

Research in this area has been the focus, and very active

1.1 Potassium-based polymer systems

In order to play as highly as possible the chemical inhibition function of metal ions, KCl and lime (CaO) are often added into the drilling fluid, as to take advantage of Ca2 + to stable the mineral lattice, and abroad this system is called potassium/calcium-based or potassium lime-based polymer system.

Domestically, high calcium system started to be put into field application around the year of 2000, which is characterized by using strong anti-calcium polymer additives and CaCl, together to form the stable drilling fluid system with Ca2 + higher than 1000mg / L (filtrate). Considering cost, during field maintenance, Ca2 + in the filtrate was usually maintained between 1200--1400mg/L, seldom more than 1600mg / L. This technique effectively plays the function of Ca2 + of improving the efficiency of the system’s chemical suppression capabilities, and greatly improves the chemical anti-sloughing ability of the potassium calcium-based drilling fluid system, and this can be considered as progress in anti-sloughing technology of drilling fluid.

1.2 Cationic Systems

With the continuous development of the chemical inhibition theory, it is recognized that the cationic group, when adsorbed in an orderly arrange to clay mineral crystal layer, can effectively squeeze out the adsorbed water molecules, so to make dehydration effect in clay minerals, that is, cationized drilling fluid system can maximize the role of inhibition of sloughing. Cation drilling fluid system started field trials in China after 1987 (or using cationized drilling fluid additives to transform the conventional drilling fluid systems), and after 1995, research and field application cases on cationic drilling fluid systems and related additives increased significantly. On the basis of the summary of the research and application of cationic drilling fluid technology for the past 10 years, Yin Ping Wu Yi, put forward for the first time in 1998 that "new research on drilling fluid will surely take as subject cationic drilling fluid systems with particles positively charged and with solid phase ". But speaking from the overall effect, the research in this area has no breakthrough yet, but the exploratory work has never stopped, and by now we still can see the reports of individual wells using cationic systems, but most of the time, using cationic additives as an inhibitor of or a coating agent.

1.3 Positive drilling fluid system

After 2000, the positive drilling fluid began to enter the field trials, which is actually a totally cationized system, and its symbol is that the potential of the system (or filtrate) should at least be larger than 0. Considering that the extremely high efficiency of neutralization for the two charges, the ξ potential of the ultimately formed positive drilling fluid should not be less than 20mV, in order to have a sufficient number of positive charges to bear the consumption of negatively charged substances mainly as cuttings, only so it can be put into field trials. Seeing from the site application of some wells, positive system is essentially a cationic system cationized at a high degree, and its potential normally is not more than -20mV (ξ potential of the traditional water-based drilling fluid normally is between -40 ~ -30mV) , and this is mainly because that the various substances into the slurry under field conditions are mostly negatively charged, plus that the positively charged additives are not mature, so usually still mainly use conventional adjuvants to maintain, while positive additives become auxiliary additives, resulting in a quick return for the positive system to conventional system in a short time. Throughout the development process of drilling fluid chemical suppression theory, in practice of anti-collapse technique, the research on positive drilling fluid system had been the point mostly expected to have revolutionary breakthrough, but because of the serious conflict between the use of theory and reality, ultimately this led to a bleak prospect for the exploration work of this technique.

1.4 KC1-- Polyamine Strong Suppression Systems

This is a strong inhibitor with small molecule mainly of poly quaternary amine (MW≤1000) type; from the molecular type, polyamine drilling fluid belongs to cationic drilling fluid family. Because the system’s suppression ability is very strong, and there is no environmental problems as caused by oil-based drilling fluids, so the research and field applications are very quick, domestic investment started for project research before or after 2007, and in 2011 it has been in large-scale application. Field application showed that the polyether amines inhibitors and inorganic salts has good synergistic effects, for example the polyether amines with conventional KC1 system can greatly improve the chemical anti-sloughing ability, and under ideal conditions its effect can be close to that of oil-based system, which cannot be done by simply increasing the content of the attachment system.

1.5 Silicate System

Silicate system has different anti-sloughing and inhibition mechanism than other common drilling fluid system, now the four recognized anti-sloughing mechanisms are as below:

(1) The chemical sediments produced by the reaction of silicate and the inorganic salts in layer water can block the micro cracks in layers, and has bridging effect for broken layers;

(2) The cementitious material produced by the recation of silicate and the neutral or weakly acidic layer water, forms a blocking shell with film effect after getting into a certain depth under the liquid column pressure into the layers.

(3) In high temperature (T≥105 ℃) silanol group of silicates and aluminol group of clay minerals have condensation reaction to produce cementing substance with good bonding effect for the broken layers;

(4) Inorganic salts companied with silicate salts can effectively reduce the filtrate activity, and reduce or eliminate osmotic pressure of the filtrate into the layers, so to have dehydration process in the layers and improve the stability. Silicate drilling fluid was put into use as early as in the 1930s, but for technical reasons until the mid-1990s was the application successful in individual wells. Field application shows that the system had outstanding ability of wellbore stability, and enabled safe drilling with lower density in complex layers.

1.6 Other Systems

The typical ones such as the organic salts systems which began to put into field application around the year of 2000, and in the late 1990s, firstly used in China's western regions. Frompopularization and application, the organic salts are mainly used for the following situations: ① as an inhibitor or water activity control agent; ② as non-solid phase systems’ weighting agent; ③for the preparation of protection system of the reservoir; ④ for the use with other salts as compound salts

In deep wells and complex layers, organic salts are generally used to maintain or improve the inhibiting ability of the chemical system suppression. Others such as polymeric polyol system, MEG oil-based-imitating system and so on, are also developed aiming to firstly improve the system anti-sloughing and inhibiting ability, then it can be seen that the ability of stabilizing wellbore of the drilling fluid system is the base for its further research and promotion.

2. Research on technology and materials of drilling fluids

2.1 Technology

2 1.1 Consolidation and control equipments

For technology, the progress of consolidation and control equipments has more significant influence on drilling technology. Before 1990n, multi-site consolidation and control equipments are mostly "a sieve (vibrating sieve) + two clearers (degritting, desilter)", and after 1995, the situation began to improve, and the most significant change is the improvement of the ability of the vibration sieve and the configuration optimization of the consolidation control system; besides, it was the enhancement of cyclone device and centrifuge, and the popularity of centrifuges’ configuration; third is the dedicated system developed by the combination of on-site work requirements, such as flow analysis and measurement system for drill cuttings. These improvements and enhancements brought 3 kinds of results: removing efficiency of cuttings was significantly improved, so the complicated situations in downhole caused by cleaning borehole were reduced a lot; because of the increase of vibration sieve, the improvement of vibration mode, and the gradual popularization of fine sieve cloth, the efficiency of once removing poor quality solid phase was greatly improved, maintenance costs reduced, and overall performance of mud cake improved. The combination and configuration of downstream consolidation control device tended to simplified, the latest consolidation control system directly took the vibrating sieve into its integrated device, and this kind of combination have a good synergistic efficacy of different consolidation control devices, and improve the removal efficiency of fine particles below 40μm.

2.1.2 Well wall coating technology

The use of light-cured reaction principle of resin generates borehole sheath on the wall, that is, "film" on the wall, which is new technology integrates stabilizing wall, leak sealing, improving layer’s pressure-bearing and the protection for the reservoir. The technology currently frequently used in domestic drilling site –"chemical inhibitor and temperature-sensitive asphaltenes coating material " is actually "natural film" for bare rock, and practice shows that this method has better performance than using a single chemical inhibitor or asphalt anti-sloughing technique.

2.1.3 Extreme technology

Due to the extreme circumstances occurred in site construction, the corresponding special operations technologies have emerged and continue to mature. Examples are ultra-high density drilling fluid used for drilling ultra-high pressure layers, ultra-low-density drilling fluid (r ≤1.00kg / L) used for drilling

layers with frequent leakings during fracture growing and layers with low pressure or pressure failure, inflated (or foam) drilling fluid, hydrocarbyl (OBM) or synthetic base (SBM) drilling technology used in high performance and strong inhibition systems for drilling extended reach wells and horizontal wells, and for the need of wellbores with frequent instability, and the ultra-high temperature (T≥200 ℃) drilling technology used in regions with unusually high temperature. From the industrial point of view, the development of such technology apparently have been greatly restricted, and the reasons: first, there are very few regions which can meet the technical requirements of this extreme technology, and this limits the application and evaluation of the technology; Second, the research and development of the materials with the extreme technical index are difficult and has long lead time, so it often requires a multi-disciplinary collaboration to complete. This situation determines that the extreme technology is still under exploration, and both research and development of materials and related theories study have a high degree of difficulty.

2.2 Materials

2 2.1 Development of chemical additives with ability of anti- hurt

Around the 1990s inorganic salts (mainly NaCl and CaSO4 or complexes of the two) especially Ca2 damage, was an on-site technical problem, while with the the materials’ ability of resistance to damage improved, by the year of 2000, the complexity caused by the inorganic salt damage began to decrease significantly, and after 2005 the performance of drilling fluid could basically be able to freely adjusted in any Cl- content.

2.2.2 Development of chemical additives adapting to all kinds of extreme conditions.

Examples are high-temperature resistance materials for strata above 220 ℃, filtrate reducer which can improve the state of hydration membrane of clay, the dispersing agent with uniform function under condition of ultra-high content of solid phase, and the filtrate reducer with chemical inhibition and so on, have been put into on-site use, and have had goods effects.

2.2.3 Developing chemical inhibitors

The more representative one is the development and use of inhibitors of the polyether amine, compared with conventional chemical inhibitors, the inhibitors of the polyamine has a stronger ability of dehydration, so they have been used in drilling operations of easily broken shales. With the in-depth study of related technology, anti-swelling and dehydration ability of chemical inhibitors will continue to be improved.

2.2.4 Application of nanotechnology in the field of drilling fluid technology

Nanotechnology’s applications in drilling industry can be traced back to the year of 2000. In 2003 Yingchuan Cui domestically for the first time published the papers of nanotechnology applications in the drilling industry, and in the same year, Yangchuan Ked, by using Nanotechnology, made organic-inorganic nanocomposite montmorillonite, which is also the first domestic report on making drilling fluid additives by nanotechnology. Compared with the research of non-penetration drilling fluid technology, research of nano drilling techniques were more rational. I think the real nano drilling fluids should have at least the following four characteristics: self-purification capacity; self-repair capacity; automatically deriving needed functions according to stratigraphic characteristics; realizing programs of daily management of drilling fluids by means of computer-assistance. In short, the real nano drilling fluid is actually a "intelligentized" working fluid, and all its operations under nano status will change radically. Speaking from the current application in the drilling fluid field, just a part of the treatment agents, through the nano-technological innovation, strengthened their original functions or derived a number of new features, while the technology basis for the "nano system" have not yet been available, so it can only called "limited use."

3. Research of balancing stress technology

Wellbore stability is essentially a mechanical problem, that is, the influences of various known or unknown factors to the wellbore stability finally go to mechanical equilibrium changes of the rocks near the wound surface of the strata. From the contemporary practice of drilling technology, options to improve wellbore stability contains the following four kinds : ① to improve the chemical inhibition ability of drilling fluids; ② to improve the ability of micro cracks plugging for drilling fluids; ③to increase its viscosity of filtrate to increase the resistance of its getting into strata, thus to reduce the quantity getting in.④ to use drilling fluid with reasonable density to balance the strata’s stress.

Among the above methods, ①, ② and ④, these three kinds of technology are essentially trying to preserve the original state of equilibrium of strata’s stress, or to minimize or eliminate the impact of external factors on the strata’s stress equilibrium; ③ is artificially to increase penetration resistance of the layers, which has evolved today to study of "film theory", and the ultimate goal is to block the transfer process of the pressure of drilling fluid column to the deep rock around the wellbore. The latest research shows that the relevance of earth stress field and wellbore stability is also one of the factors combined into research practice. I believe that the exploratory study of the relation between earth stress field and wellbore stability relationship is important for wellbore instability forecasting, especially with a great guiding significance for the trajectory design of large displacement wellbores and ultra-deep drilling job security.

4. Research of the impact of energy changes on wellbore stability

Due to the fact that there are a large number of factors affecting wellbore stability, and that there are complex constraints relationships among various factors, the anti-sloughing technology in drilling engineering has blindness, low or no efficiency. Some scholars attempt to analyze the wellbore instability problems from the perspective of energy conservation, such as Jiafang Xu , after his study, thinks that when the energy accumulated inside becomes unaffordable for the rock, then it releases in the form of expansion of micro-cracks, when the internal energy changes into surface energy through expansion of micro-crack generation and interaction. From a physical point of view, this view is actually another way of expression of change in the balance of rock mechanic equilibrium state, and it shows us clearly that the wellbore stability can also be achieved by reducing or delaying the accumulation of the internal energy of the rock, but the key is how this theory turns into effective technical means. In the research and treatment on wellbore stability problems, this is the biggest contradiction between theory and practice, also one of the reasons that there are technical gray area in this field.

5. Other aspects of research

In addition to the above main areas, drilling researchers at home and abroad also had study on the experimental methods and evaluation methods, the application of computer technology and so on, and they had made some progress.

5.1 Analysis and Evaluation of Experimental Methods and Evaluation Methods

Studies suggest that there are some problems in the current testing method based on the API specification, as which cannot effectively evaluate the effect of using the drilling fluid additives:

(1) API specification are "static" standard, from which, conclusions or data are also a static point, and cannot objectively reflect the parameters changes of the drilling fluid under dynamic conditions.

(2) The direct object of the drilling fluid in actual operation is layers (well wall), and the main changes of technical parameters of drilling fluid are due to the changes of the layers, but all the experimental procedures did not involve layer factor; Therefore a series of parameters obtained from the reference to API specification only shows that the situation when objective environment and experimental environment are closer, with a great chance.

(3) Some of the key issues did not get attention, because there is no appropriate experimental means to analyze and evaluate, typically as cake formation and destruction process and the dispersion process of bentonite. The final effect of drilling fluid on layers is reflected in the quality of the cake, and if there is no specific quantitative target, there is no way to judge the specific effect.

(4) The current standard is unable to organically integrate the technical state of the two endpoints –micro and macro- in project, mainly in two aspects: Indoor can not simulate the real live operating environment, and experimental data got from through using dynamic testbed simulating the real environment is in lack of the standardization; due to differences in operational aspects, the amplification sample is quite different from industrial products like indoor performance was quite different, so it is not possible to evaluate by experimental methods.

For more information, please visit Zoranoc's official website:www.zoranoc.com