Article Archive

Article Archive

- Introduction of Cement Slurry System (Part 1)

- Introduction of Cement Slurry System (Part 2)

- Introduction of Cement Slurry System (Part 3)

- Introduction of Cement Slurry System (Part 4)

- High Temperature and High Pressure Cementing Technology

- Low Density Cementing Slurry Technology

- Anti Gas Channeling Cementing Technology

- Drag Reducing Agents (DRA) or Drag Reducers (DR)

- Nitrogen Surfactant Compound Huff and Puff Technology

- Oil Washing Technology for Increasing Production

3.4 performance of low density cement slurry containing ZOC-H50S

At present, some domestic oilfields are faced with the problems of long cementing section cementing in deep wells and long cementing section cementing with low pressure and easy leakage. Because of the large temperature difference between the upper and lower parts of the long cement column in the sealing section, the formation pressure bearing capacity is low, and the leakage is easy to occur during cementing. The application of double-stage cement slurry cementing technology has certain risks and limitations, so the low-density cement slurry system should be adopted. The performance of four kinds of low density cement slurry systems with ZOC-H50S dosage of 1.8% were evaluated (see Table 4). The bottom hole circulation temperature was 130 ℃ and the top temperature was 30 ℃. The results show that the fluidity of low-density cement slurry containing ZOC-H50S is 21-23cm, the thickening time is adjustable, and the slurry has good stability. When the slurry returns to the top temperature of 30 ℃ once, the strength is more than 7MPa in 96h, which can meet the requirements of cementing operation.

Table 4: performance of low density cement slurry containing ZOC-H50S

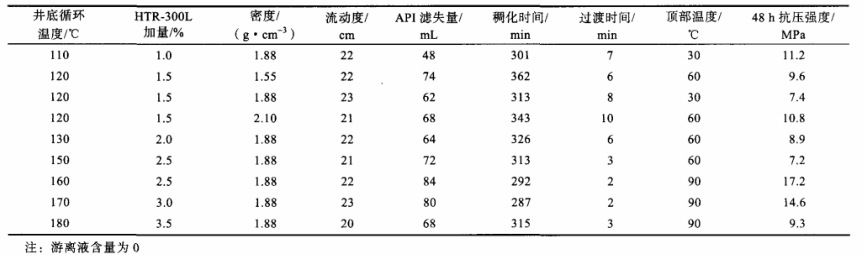

3.5 applicability evaluation of cement slurry containing ZOC-H50S

Table 5 shows the performance of cement slurry system with different ZOC-H50S dosage under different bottom hole circulation temperature. It can be seen that under different bottom hole circulation temperature, the fluidity of slurry with different density containing ZOC-H50S is 20 ~ 23cm, API filtration rate can be controlled within 100ml, thickening time is adjustable, transit time is short, basically "right angle" thickening, and the top strength of cement slurry column develops well under large temperature difference. Therefore, ZOC-H50S is suitable for a wide range of temperature, and is suitable for high and low density cement slurry system. The slurry containing ZOC-H50S has good comprehensive performance, and is easy to adjust and control, which can meet the requirements of cementing operation in long cementing section.

Table 5: performance of slurry systems with different ZOC-H50S dosages at different bottom hole circulation temperatures

4. Conclusion

The high temperature retarder ZOC-H50S was synthesized by designing the molecular structure reasonably. The results of infrared spectrum analyzer showed that the synthesized product was the target product.

In order to evaluate the high temperature retarding property of ZOC-H50S, the thickening properties of different dosages of ZOC-H50S cement slurry were tested at different temperatures, and the differential thermal analysis and thermogravimetric analysis were carried out. The results show that ZOC-H50S has good high temperature retarding performance, suitable for bottom hole circulation temperature of 70 ~ 200 ℃, and can effectively adjust the thickening time of cement slurry by adjusting the dosage of ZOC-H50S according to different cementing requirements; when the temperature is higher than 266 ℃, ZOC-H50S has obvious heat change and mass loss, and its molecular structure is stable and its high temperature resistance is good.

The test results of cement thickening time with different salt content and ZOC-H50S dosage show that ZOC-H50S has good salt resistance and can be used in cementing operation of saline mud system.

The strength development, thickening time, fluidity and API filtration rate of ZOC-H50S cement slurry system under different top and bottom temperature differences are analyzed. The results show that the strength development of ZOC-H50S cement slurry system is good under large temperature difference, which can solve the problem of super retarding setting of top cement slurry in long cementing section; ZOC-H50S has a wide range of operating temperature and is suitable for high and low density cement slurry systems; ZOC-H50S cement slurry system with ZOC-H50S is suitable for high and low density cement slurry systems It is easy to adjust the cementing performance and meet the requirements of long cementing operation.