Article Archive

Article Archive

- Introduction of Cement Slurry System (Part 1)

- Introduction of Cement Slurry System (Part 2)

- Introduction of Cement Slurry System (Part 3)

- Introduction of Cement Slurry System (Part 4)

- High Temperature and High Pressure Cementing Technology

- Low Density Cementing Slurry Technology

- Anti Gas Channeling Cementing Technology

- Drag Reducing Agents (DRA) or Drag Reducers (DR)

- Nitrogen Surfactant Compound Huff and Puff Technology

- Oil Washing Technology for Increasing Production

3.2 salt resistance

In order to adapt to different formation environment, the retarder should not only have good high temperature retarding performance, but also have good salt resistance. Table 2 shows the test results of thickening time of cement slurry with different salt content and ZOC-H50S dosage at 130 ℃. It can be seen that the thickening time of cement slurry with 8% salt content is basically the same as that of fresh water cement slurry (salt content is 0); the thickening time of cement slurry with 15% salt content is longer than that of fresh water cement slurry, and the thickening time increases with the increase of ZOC-H50S dosage. This may be because salt solution is a kind of strong electrolyte, and strong electronegativity C1 ¯ is coated on the surface of cement particles, which destroys the reversible equilibrium state of water molecules and partly "shields" the contact between water and cement particles, thus making the cement slurry thickening time longer. Other retarders also have the phenomenon that the thickening time of brine slurry is longer than that of fresh water cement slurry. Figure 4 shows the thickening curve of cement slurry with 2.2% ZOC-H50S (15% salt content) at 130 ℃. It can be seen that the consistency curve is stable, without "bulge" and "core" phenomenon, short transition time and basically "right angle" thickening. Therefore, ZOC-H50S has good salt resistance and can be used in cementing operation of saline mud system.

Table 2: salt resistance evaluation results of ZOC-H50S

Figure 4: thickening curve of cement slurry with 2.2% ZOC-H50S (15% salt content) at 130 ℃

3.3 strength development of cement slurry containing ZOC-H50S under large temperature difference

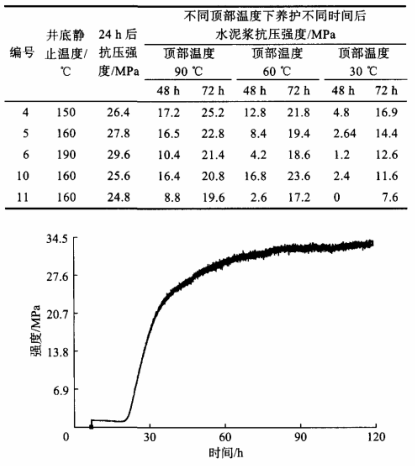

Table 3 shows the strength development of different cement slurry systems under different top and bottom temperature differences. It can be seen that the compressive strength is more than 20MPa after curing at different bottom hole static temperature for 24h after thickening time is more than 300min. Curing at different top temperatures showed good early strength: the strength of cement slurry with 8% salt content (No. 10 cement sample) was basically the same as that of fresh cement slurry (No. 5 cement sample); the cement slurry with cement content of 15% (11 cement sample) developed slowly at low temperature, but the strength after 72h was greater than 7.5MPa. Figure 5 shows the static gel strength development curve of fresh water cement slurry with ZOC-H50S dosage of 2.0% at 70 ℃. It can be seen that the strength of the cement slurry starts to develop rapidly at 20h, reaches above 14MPa at 28h, and exceeds 30MPa at 96h, and then it still tends to increase. Therefore, the slurry system containing ZOC-H50S can be used to solve the problem of super retarding of cement slurry at the top of long cementing section.

Table 3: strength development of cement slurry under different top and bottom temperature difference

Figure 5: static gel strength development curve of fresh water cement slurry with ZOC-H50S dosage of 2.0% at 70 ℃

.jpg)