Article Archive

Article Archive

- Introduction of Cement Slurry System (Part 1)

- Introduction of Cement Slurry System (Part 2)

- Introduction of Cement Slurry System (Part 3)

- Introduction of Cement Slurry System (Part 4)

- High Temperature and High Pressure Cementing Technology

- Low Density Cementing Slurry Technology

- Anti Gas Channeling Cementing Technology

- Drag Reducing Agents (DRA) or Drag Reducers (DR)

- Nitrogen Surfactant Compound Huff and Puff Technology

- Oil Washing Technology for Increasing Production

1.2 synthesis method

A certain amount of deionized water was added into a four port flask with thermometer, stirrer and reflux condenser tube, then amps (2-acrylamido-2-methylpropanesulfonic acid), IA (itaconic acid) and Dy were successively added, and NaOH solution was added at a certain stirring speed to adjust the pH value of the reaction system. After that, the initiator solution was added to the reaction system after the reactants were completely dissolved, and then the temperature was raised and refluxed for 2 h. Finally, a colorless liquid retarder ZOC-H50S (effective concentration of 30%) was obtained by natural cooling to room temperature.

2. ZOC-H50S infrared spectrum analysis

After separation and purification with propanol, ZOC-H50S was analyzed by ft-s3000 FT-IR spectrometer. According to the infrared spectrum of ZOC-H50S

.png)

The results show that 3300.99cm¯¹ is the stretching vibration absorption peak of N-H; 2938.71cm¯¹ is the stretching vibration absorption peak of - CH Theil; 1637.66cm is the stretching vibration absorption peak of C = O in the sulfonic group of AMPS; 1299.57cm¯¹ and 1054.59cm¯¹ are the symmetric and asymmetric stretching vibration absorption peaks of S = O in the sulfonic group of AMPS; 1499.23cm¯¹ and 1369.85cm¯¹ are the symmetric and asymmetric stretching absorption peaks of C = O in carboxylic acid group of IA; 3084.69cm¯¹ and 1369.85cm are the symmetrical and asymmetric stretching absorption peaks of C = O in carboxylic group of IA, respectively The results show that 860.31cm¯¹ is the absorption peak of C-H in Dy, 767.51cm¯¹ is the vibrational absorption peak of C-N bond in Dy, there is no characteristic absorption peak of C = C in 1620.00~ 1635.00 cm¯¹, indicating that there is no unsaturated monomer in ZOC-H50S, which is the target product.

3. Performance evaluation of cementing retarder ZOC-H50S

3.1 high temperature retarding performance

Generally, with the increase of temperature, if the thermal degradation chain breaks, the polymer retarder will have obvious heat change and mass loss, and the retarding effect will be greatly reduced or even completely lost. Therefore, retarders need to maintain good retarding effect at high temperature. In order to evaluate the high-temperature retarding performance of ZOC-H50S, the thickening properties of different dosages of ZOC-H50S cement slurry system were tested at different temperatures (table below and below). The base slurry formula was grade G oil well cement + 35.0% silica fume + 4.0% fluid loss reducer ZOC-G712H-L + 0.6% sulfonated acetone formaldehyde dispersant ZOC-F46L + 48.3% clean water.

Table 1: test results of thickening performance of cement slurry containing ZOC-H50S

.png)

Figure 2: relationship between thickening time and temperature of slurry containing ZOC-H50S

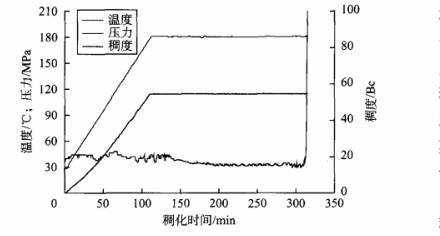

Figure 3: thickening curve of 4.0% ZOC-H50S cement slurry at 180 ℃

.jpg)