Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

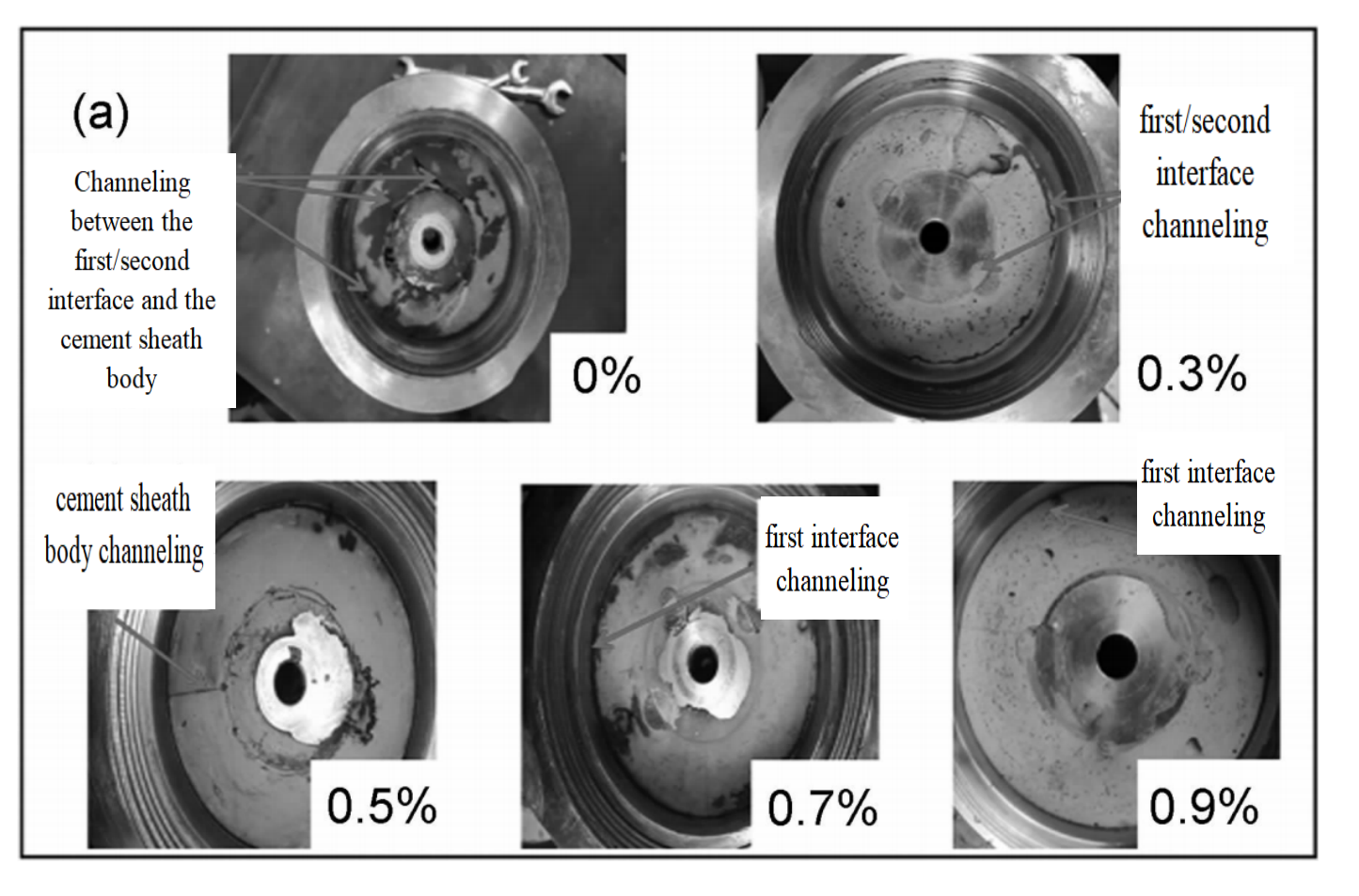

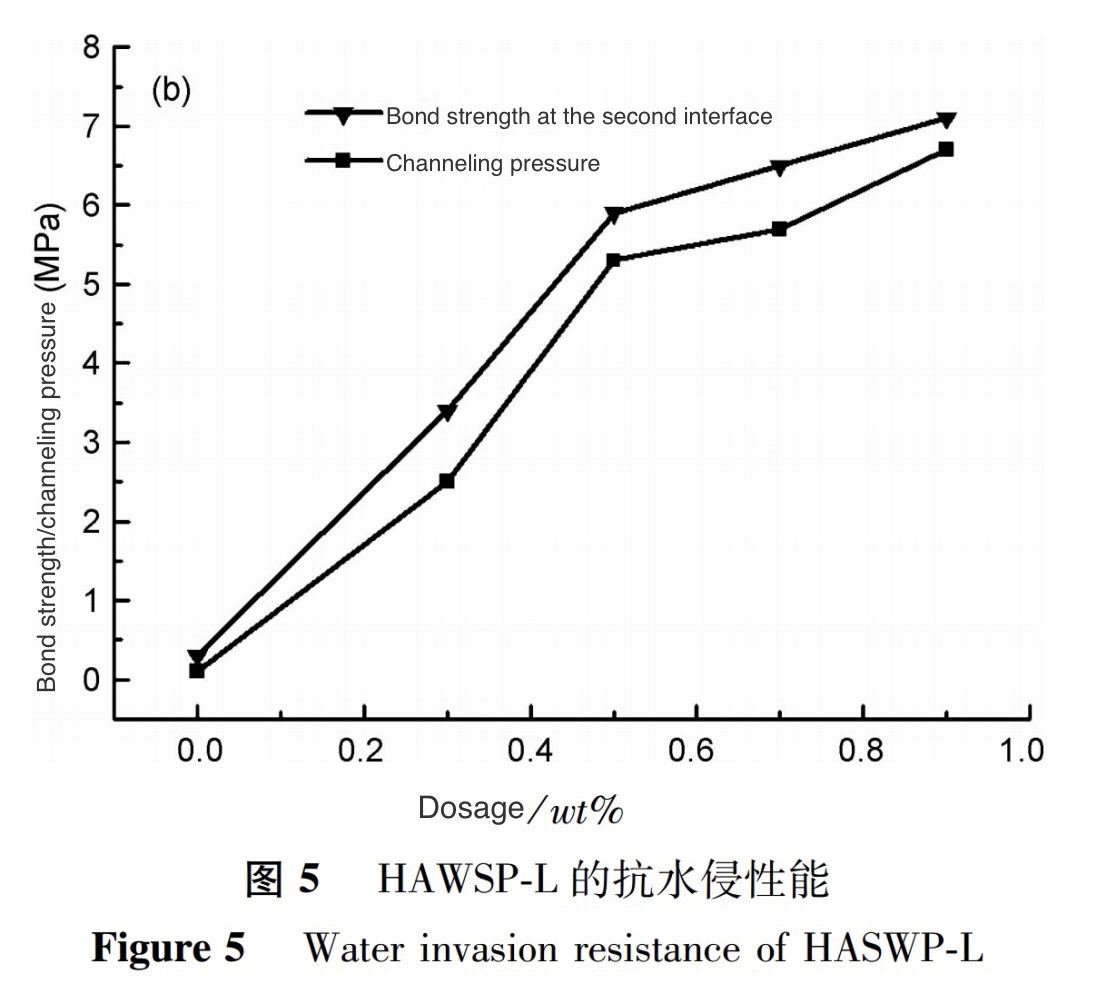

(2) The Effect of Different Dosages of HAWSP-L on the Anti Water Invasion Performance

The effect of different dosages of HAWSP-L on the water invasion resistance of cement slurry was tested using a dynamic pressure of 0-5MPa as the water invasion pressure. The results are shown in Figure 5. From Figure 5, it can be seen that the bonding strength and channeling pressure of the secondary interface of the annular cement slurry increase with the increase of HAWSP-L dosage. When the dosage of HAWSP-L is 0.3%, the bonding strength and channeling pressure at the second interface of the annular cement slurry are 3.4 and 2.5 MPa, respectively; When the dosage of HAWSP-L is 0.9%, the bonding strength and channeling pressure at the second interface of the annular cement slurry are 7.1 and 6.7 MPa, respectively. This indicates that HAWSP-L has good water invasion resistance to cement slurry, and the larger the dosage, the better the water invasion resistance.

(3) SEM

Figure 6 shows the microstructure of cement paste after solidification in a cement slurry system containing HAWSP-L. From Figure 6, it can be seen that under the action of dynamic pressure water intrusion, the surface of the solidified cement matrix without anti channeling agent is loose, and there are obvious water flow impact holes (a); After the slurry containing HAWSP-L solidifies, the surface of the cement stone matrix is dense and there are no obvious impact pores (b). This indicates that the anti channeling agent HAWSP-L improves the resistance of cement slurry to dynamic pressure water intrusion during the waiting period, and enhances the anti channeling ability of solidified cement paste.

.png)

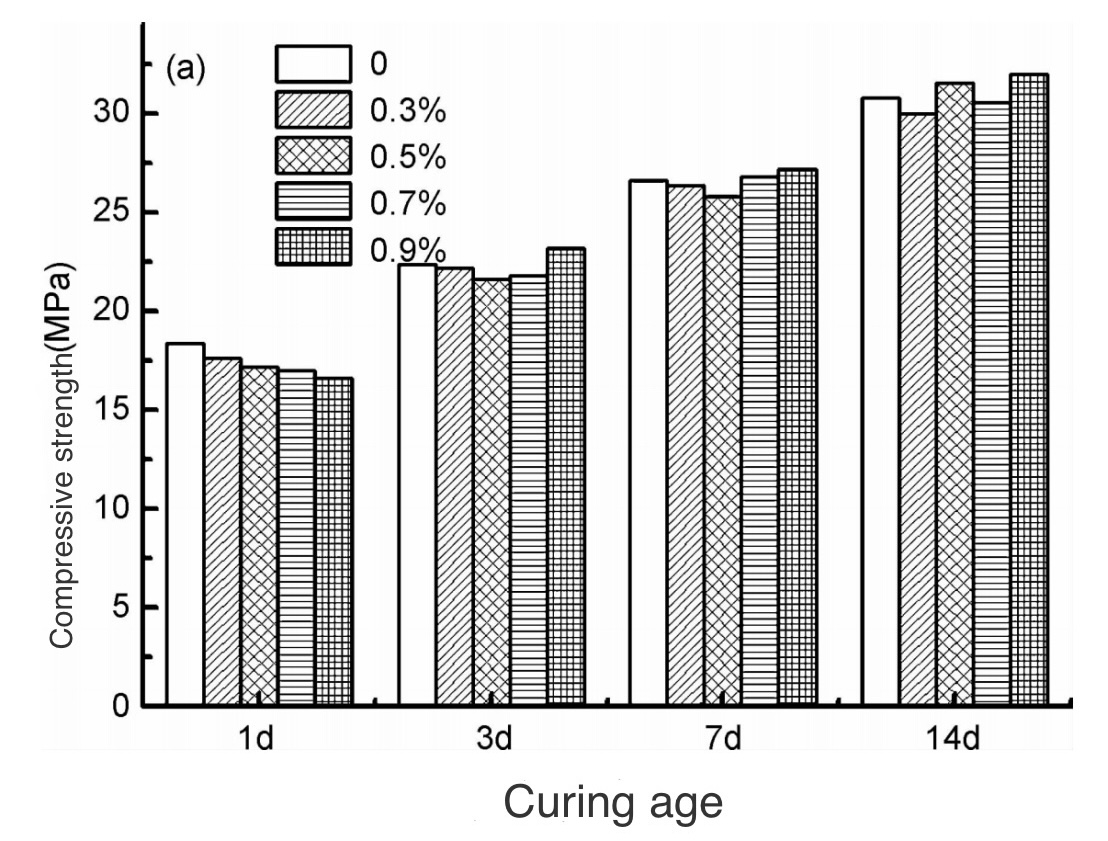

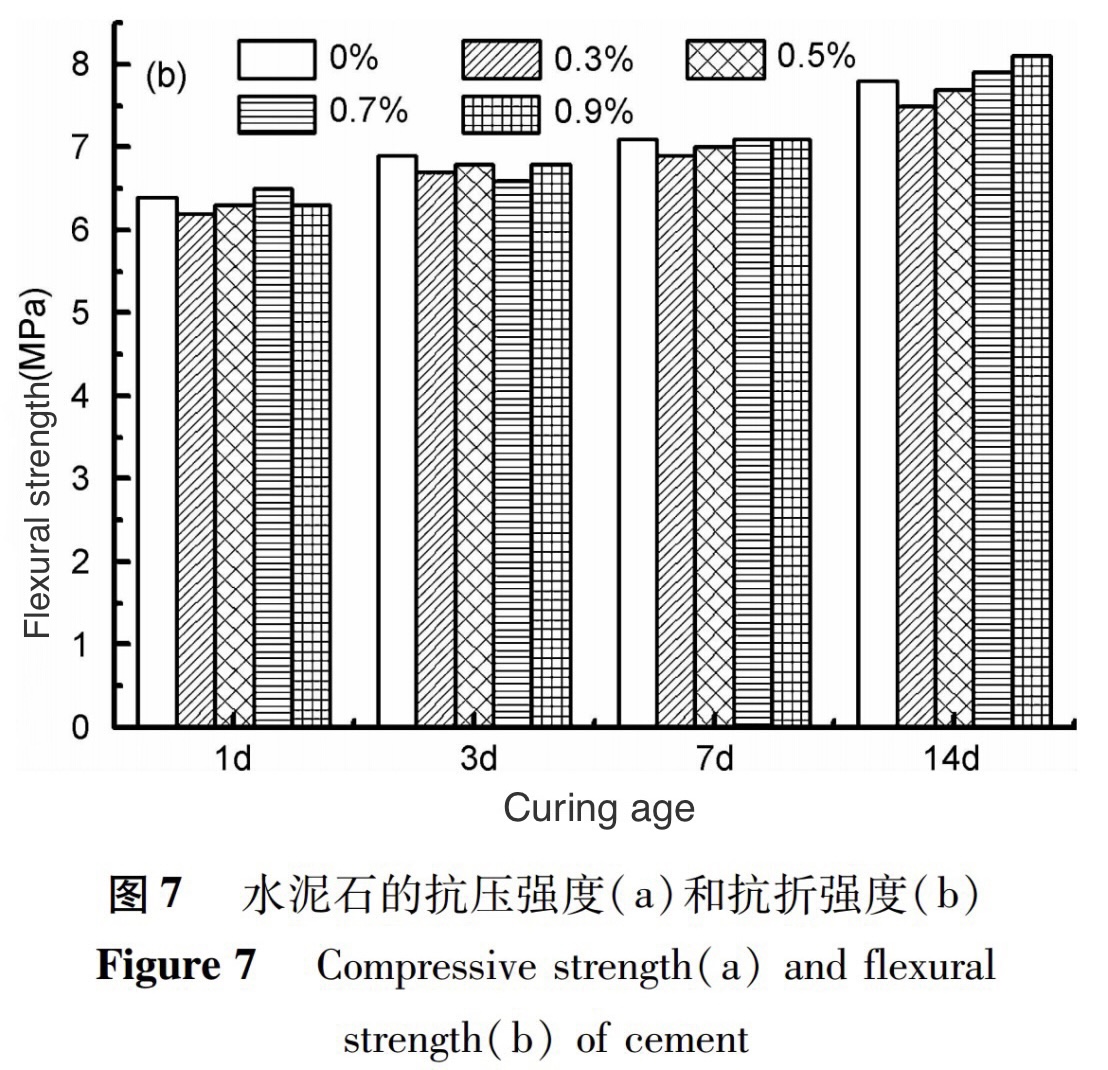

(4) Mechanical Properties of Cement Paste

Figure 7 shows the effect of HAWSP-L on the mechanical properties of cement paste. As shown in Figure 7, at 1d and 14d, the compressive strength of the blank cement stone is 18.4 and 30.8 MPa, while the flexural strength is 6.3 and 7.7 MPa, respectively; The compressive strength of the cement paste added with 0.9% HAWSP-L is 17.4 and 31.4 MPa, respectively,while the flexural strength is 6.4 and 8.3 MPa, respectively. This indicates that HAWSP-L has no adverse effects on the short-term and long-term compressive and flexural strength of cement paste.

(5)Thickening Time

Figure 8 shows the thickening curve of anti channeling cement slurry at 60℃ and 19.4MPa. As shown in Figure 8, the thickening time of the blank cement slurry is 219 minutes (100Bc), while the thickening time of the 0.5% HAWSP-L cement slurry is 258 minutes (100Bc). This indicates that HAWSP-L has a slight retarding effect on cement slurry. In addition, the thickening curve of cement slurry containing HAWSP-L did not show any abnormal phenomena such as "bulging" or "stepping". The transition time of 30-100Bc was less than 15 minutes, and it basically showed a right angle thickening. This is conducive to protecting the good suspension stability and annular anti channeling performance of the slurry, and can ensure the safety and smooth progress of on-site cement injection construction.

.jpg)

(6) Engineering Performance

Table 1 shows the effect of HAWSP-L on the engineering performance of cement slurry. From Table 1, it can be seen that HAWSP-L has a significant impact on the flowability of cement slurry. When HAWSP-L is not added, the fluidity of cement slurry is 24cm. After adding HAWSP-L, the fluidity of cement slurry decreases, and the flow of cement slurry decreases with the increase of HAWSP-L, which is caused by the viscosity increasing effect of HAWSP-L. From Table 1, it can also be seen that the water loss of cement slurry decreases with the increase of HAWSP-L. The API water loss of cement slurry with 0.5% HAWSP-L is 51mL. This indicates that HAWSP-L has a certain water loss control effect, which is because the polar groups such as sulfonic and carboxylic groups in HAWSP-L have a good adsorption effect on cement particles, and HAWSP-L has a strong binding force on water molecules in cement slurry.

.png)

3. Conclusion

This article synthesized a new type of quaternary water-soluble hydrophobic association polymer HAWSP-L and studied its effect on the water invasion resistance of cement slurry under dynamic pressure cementing conditions. The results indicate that HAWSP-L has good water invasion resistance, and the anti channeling pressure of cement slurry containing HAWSP-L reaches 5.3MPa. HAWSP-L has no adverse effect on the mechanical properties of cement paste.