Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

Abstract

A water-soluble hydrophobic association polymer anti channeling agent HAWSP-L for well cementing slurry was synthesized using AMPS, AM, MA, and St as raw materials and free radical micelle polymerization method to address the issue of annular flow caused by water invasion under dynamic pressure. Its structure was characterized by IR and SEM. The performance evaluation results of cement slurry added with HAWSP-L indicate that HAWSP-L has good water invasion resistance, and the anti channeling pressure of cement slurry containing HAWSP-L reaches 5.3MPa.

Due to long-term water injection development, the formation pressure of water injection wells is disordered, coupled with imbalanced injection and production, as well as annular pressure during the cement injection process, dynamic pressure is formed in the formation. Under dynamic pressure, formation water will continuously disturb the annular cement slurry during the waiting process, causing the slurry to be in a fluctuating waiting state, affecting the bonding quality of the secondary interface, thereby damaging the integrity of the cement sheath interlayer sealing, inducing formation fluid flow, affecting normal production of oil wells, and even leading to oil well scrapping. Developing materials with good water invasion resistance and designing anti water invasion and anti channeling cement slurry systems are important measures to ensure the quality of adjustment well cementing.

Hydrophobic association polymer is a polymer with a small amount of hydrophobic groups in the hydrophilic chain (less than 2% of the total monomer mole fraction). In low concentration hydrophobic associating polymer solutions, due to the influence of hydrophobic groups in polymer molecules, aggregates mainly composed of intramolecular associations are formed, causing the macromolecules of the polymer to curl, resulting in a decrease in its hydrodynamic volume and intrinsic viscosity. When the concentration of hydrophobic associating polymers in the solution exceeds the critical value, the macromolecular chains of hydrophobic associating polymers will form a supramolecular network structure dominated by intermolecular association, which will be destroyed under high shear. But when the shear effect is eliminated, the "cross-linked network" between polymer macromolecules will regenerate, causing the viscosity of the solution to recover again. Therefore, hydrophobic associating polymers are beneficial for maintaining the stability of cement slurry and improving its anti channeling ability.

In view of this, a novel quaternary hydrophobic association polymer HAWSP-L was synthesized using 2-acrylamido-2-methylpropane sulfonic acid (AMPS), acrylamide (AM), maleic anhydride (MA) and octadecyl acrylate (St) as monomers, sodium dodecyl sulfate (SDS) as surfactant, and potassium persulfate as initiator, and using free radical micelle synthesis method. Its structure was characterized by IR and SEM, and the water resistance and compressive performance of cement slurry containing HAWSP-L were studied.

1. Experimental Part

1.1 Instruments and Reagents

▪ WQF520 infrared spectrometer (KBr tablet);

▪ FEI Quanta450 scanning electron microscope;

▪ NYL-300 pressure testing machine;

▪ DKZ-500 electric bending machine.

▪ AMPS, AM, MA, St, SDS, analytical pure, Chengdu Kelong Reagent Factory;

▪ G-grade oil well cement, industrial product, Sichuan Jiahua Cement Factory;

▪ SXY dispersant, SWJ-1 fluid loss additive, industrial product, Chengdu Chuanfeng Chemical Engineering Co., Ltd;

▪ X60L defoamer, Weihui Chemical Co., Ltd;

▪ All other reagents used are analytical pure.

1.2 Synthesis

Add monomers with a mass ratio of AM/AMPS/MA/St=100/15/10/2 and 20mL deionized water. The amount of surfactant SDS is 0.35% of the total amount of reaction monomers. Add 50mL deionized water and adjust to pH neutral. The initiator amount is 0.44%. React under nitrogen protection at 60℃ to the endpoint. Wash with ethanol and freeze dry the product for later use.

1.3 Performance Testing

Basic cement slurry system: Jiahua G-grade cement+0.3% SXY dispersant+1% SWJ-1 fluid loss additive+0.2% X60L defoamer+44% water.

(1) Water Intrusion Resistance

Simulate the process of formation water invading cement slurry under dynamic pressure using a self-made annular dynamic pressure channeling tester. Using simulated formation water as the water source, inject water into the water inlet of the bottom cover of the kettle through an advection pump, and dynamically adjust the water pressure: Firstly, slowly apply water pressure to the cement slurry in the tester until the test pressure is 5.0MPa, maintain the pressure for 1 hour, slowly release the pressure to normal pressure, and maintain the normal pressure for 30 minutes. Cycle until the final setting of the cement slurry, cure at 60 ℃ for 1 day, and test the breakthrough pressure and bonding strength of the cement slurry at the second interface.

(2) Mechanical Property

Determine the effect of different dosage of HAWSP-L on the compressive and flexural strength of cement paste according to literature methods.

(3) Other Properties

The thickening performance of cement slurry was tested in accordance with the "SY/T 5504.4-2008 Evaluation Method for Oil Well Cement Admixtures" and the "SY/T 6544-2017 Performance Requirements for Oil Well Cement Slurries".

2. Results and Discussion

2.1 Characterization

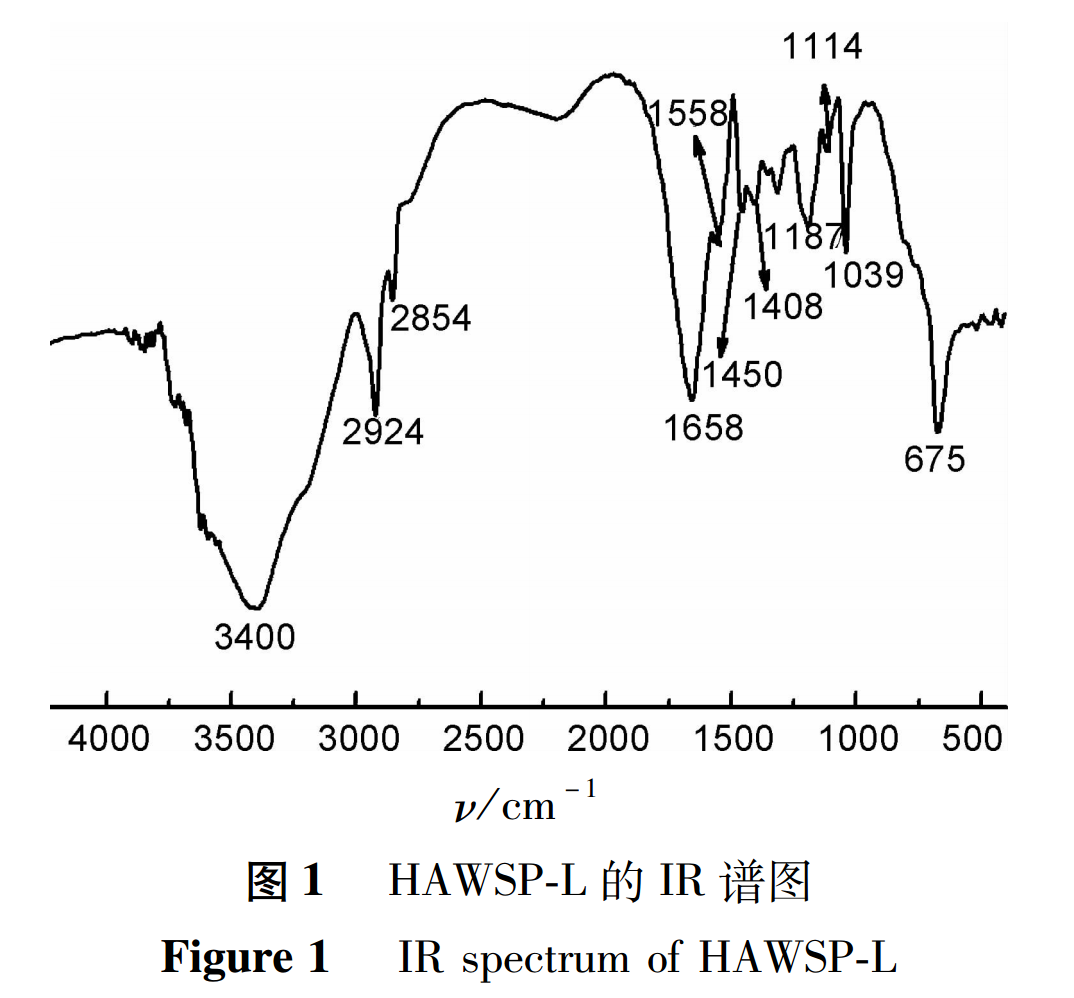

(1) IR

Figure 1 shows the IR spectrum of the polymer. As shown in Figure 1, the characteristic peak at 3443cm-1 is the stretching vibration absorption peak of hydroxyl and N-H in AM, the characteristic peaks at 2930 and 2864cm-1 are the vibrational absorption peaks of St's methylene group, the characteristic peak at 1673cm-1 is the stretching vibration absorption peak of C=O, and the characteristic peak at 1420cm-1 is the bending vibration absorption peak of methyl group. The characteristic peak at 1195cm-1 is the characteristic absorption peak of C-O-C in St, and the characteristic peaks at 1120 and 1198cm-1 are the stretching vibration characteristic absorption peaks of sulfonic groups in AMPS, there is no characteristic peak between 900 and 1000cm-1, indicating that the polymer does not contain C=C. The characteristic peaks at 1445 and 1560cm-1 are vibration absorption peaks of carboxyl groups in MA.

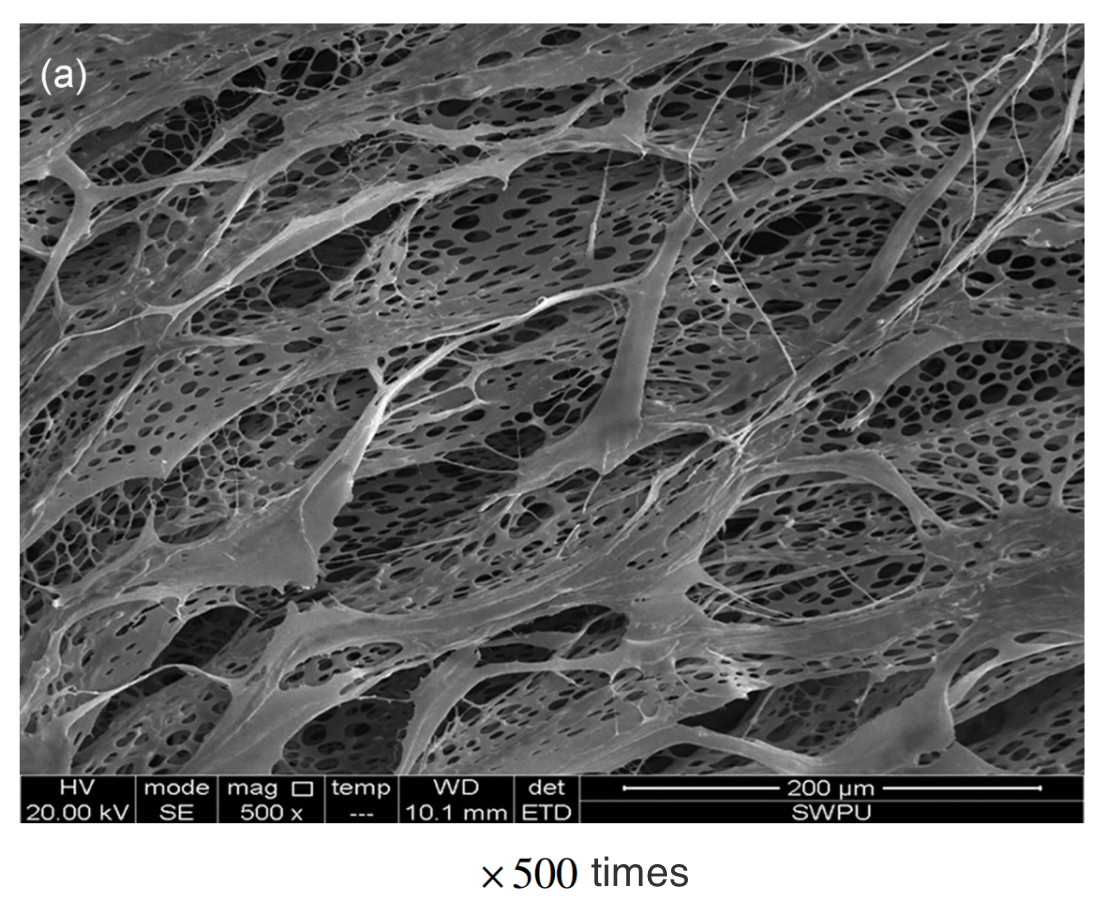

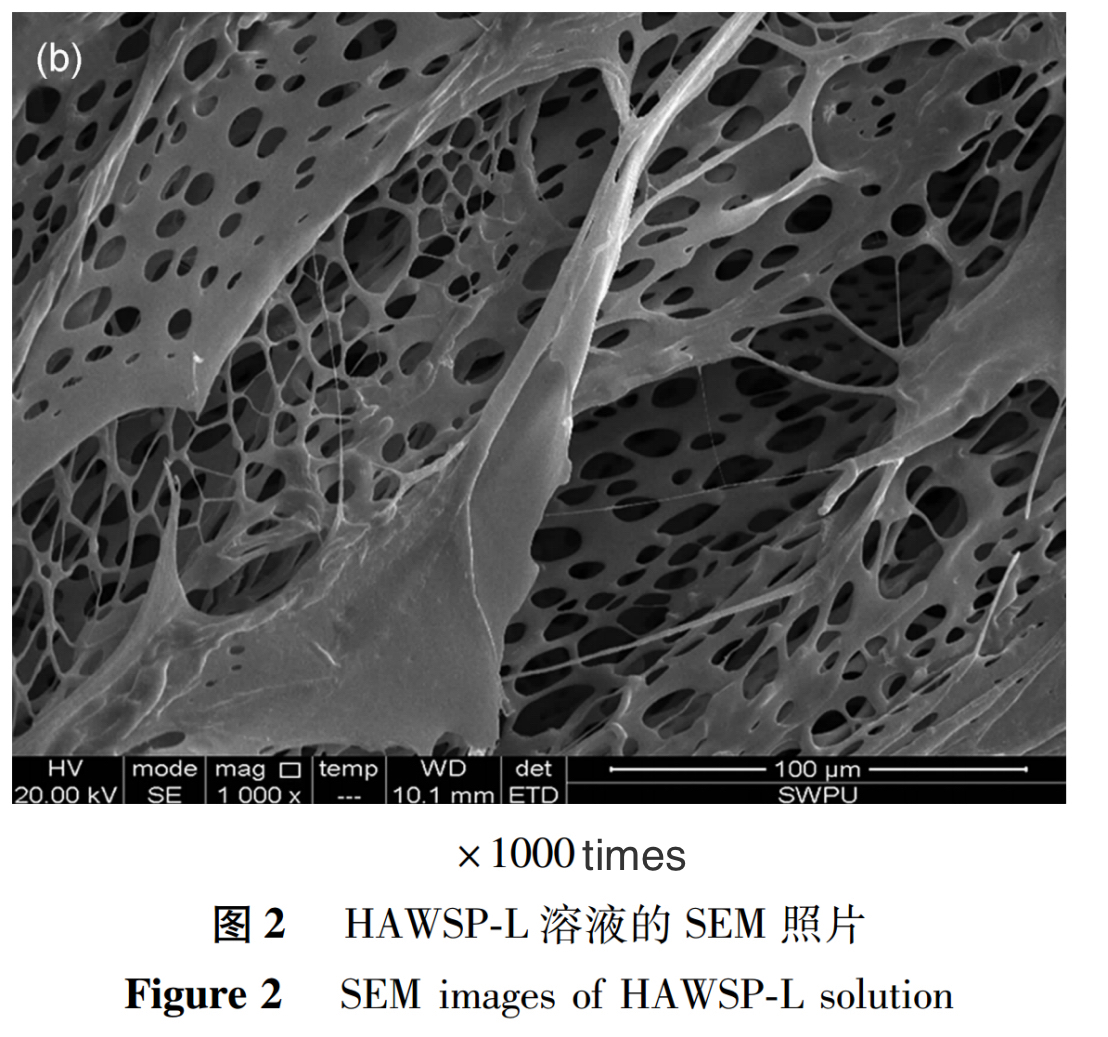

(2) SEM

Figure 2 shows SEM photos of HAWSP-L solution. From Figure 2, it can be seen that the HAWSP-L solution exhibits a cross-linked network, and the hydrophobic interaction of the HAWSP-L hydrophobic groups causes polymer molecules to form a supramolecular network in water. That is, under the association effect of hydrophobic associating polymers, intermolecular association causes the polymer to form supramolecular aggregates. The formation of this network structure in the solution is beneficial for enhancing the cohesive force of hydrophobic associating polymers on the cement slurry components, thereby enhancing the ability of the cement slurry to resist external interference during the waiting period, and ultimately improving the anti channeling ability of the cement sheath.

2.2 Performance

(1) Water Intrusion Resistance

Figure 3 shows the effect of water invasion pressure on the channeling pressure. From Figure 3, it can be seen that when the cement slurry is not invaded by water, the channeling pressure and second interface bonding strength of the annular cement stone are 4.6 and 4.8 MPa, respectively. After being invaded by water under a dynamic pressure of 5 MPa, the channeling pressure and second interface bonding strength are 0.3 and 0.1 MPa, respectively.

.jpg)

We evaluated the anti channeling ability of cement slurry without anti channeling agent and cement slurry with 0.5% HAWSP-L under a dynamic pressure of 0-5MPa as the water invasion pressure. The results are shown in Figure 4. From Figure 4, it can be seen that under dynamic pressure water invasion, large cracks appear in the cement sheath body and interface after the cement slurry without anti channeling agent has set. When using the annular dynamic pressure channeling tester to measure the channeling, there was a phenomenon of channeling at both the main body and the second interface of the cement sheath, with a channeling pressure of only 0.1MPa. After setting, the cement slurry with 0.5% HAWSP-L showed no obvious cracks or pores in the cement sheath and the secondary interface. When using the annular dynamic pressure channeling tester to measure the channeling, there was a channeling phenomenon in the cement sheath body, but the channeling pressure was 5.3MPa, significantly higher than the 0.1MPa of the comparison system. This indicates that the synthesized HAWSP-L improves the water intrusion resistance of the cement slurry during dynamic pressure setting, resulting in good anti channeling ability of the solidified cement sheath.

.png)