Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.3 Emergency Rescue Technology for Blowout

2.3.1 Blowout emergency rescue technology

Although well control technology has made significant progress, its theory, technology, and management are still not very perfect, and it is necessary to develop emergency rescue technology for blowout. Chuanqing Drilling Company has taken the lead in establishing the first oil and gas well firefighting company in China, and has become a national oil and gas field rescue Guanghan base, a standing force for emergency rescue of cross-border production safety accidents, and a China Petroleum Well Control Emergency Rescue Response Center. It has successfully completed more than 50 rescue operations both domestically and internationally, breaking multiple world oil and gas well rescue records (Figure 5).

Since the 1970s, the United States and Canada have established multiple specialized service companies, mostly subsidiaries of large oil and gas field technology service companies. At present, internationally renowned well control emergency service companies mainly include Boots&Coots, Wild Well Control, Cudd Well Control in the United States, and Safety Boss in Canada. Their service areas include the Middle East, Central Asia, North America, and other regions. Typical successful cases include the extinguishing of oil wells in Kuwait caused by the Gulf War, and the disposal of blowouts, explosions, and fires on the Deepwater Horizon offshore drilling platform in the Gulf of Mexico.

After the blowout is out of control and catches fire, the traditional approach is to first extinguish the fire and then rescue it. However, the risk of re ignition after extinguishing the fire is high, and there is a high risk of flash explosions and personnel poisoning. Therefore, we have independently developed a wellhead reconnaissance robot with image acquisition and transmission functions, as well as peripheral environment detection functions.

We have developed specialized equipment such as a 65 MPa/800 mm long-distance hydraulic sandblasting cutting device and an integrated wellhead reset device, forming a series of five well control emergency rescue technologies: dangerous situation reconnaissance, cooling cover, cutting and clearing, wellhead reset, and collaborative decision-making. We have also developed a full process fire operation technology, with a formation pressure of 70 MPa, emergency rescue capability for uncontrolled well blowout with a natural gas flow rate of 200×104 m3/d. In response to the potential well control hazards caused by corrosion, erosion, and rusting of wellhead equipment, specialized equipment such as 105 MPa frozen temporary plugging device, 105 MPa pressurized drilling device, and annular groove machine have been successfully developed both domestically and internationally, forming mature process technology. It has been applied on a scale of over 200 wells in Sichuan Chongqing, Changqing, and other areas, with a maximum wellhead operating pressure of 50.2 MPa and a maximum hydrogen sulfide content of 5.333 g/m3.

2.3.2 Rescue well technology

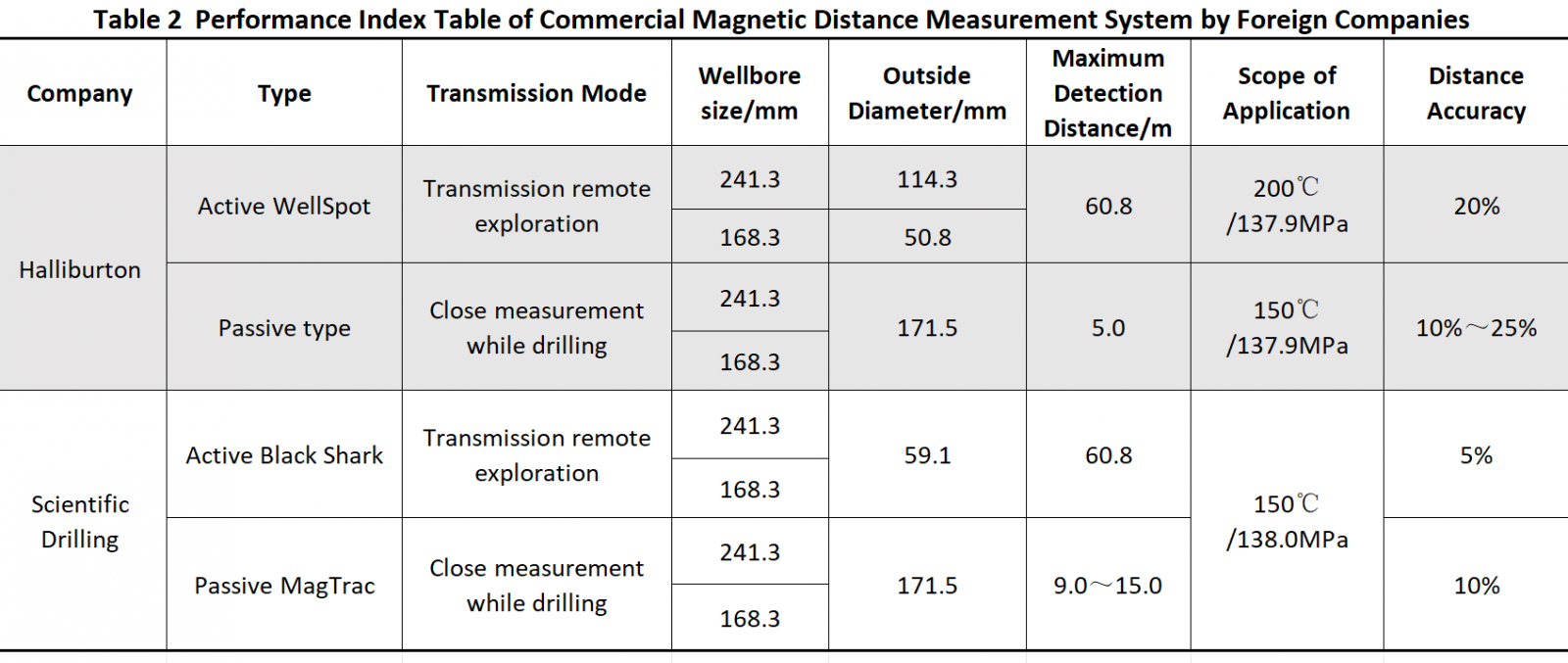

As an important link in the complete industrial chain of well control, foreign rescue well technology has developed for many years. Halliburton, Scientific Drilling, and other companies have formed a relatively complete set of rescue well technology and service capabilities, which can complete rescue well operations such as relief wells, intervention wells, and offshore "U" shaped tube wells.

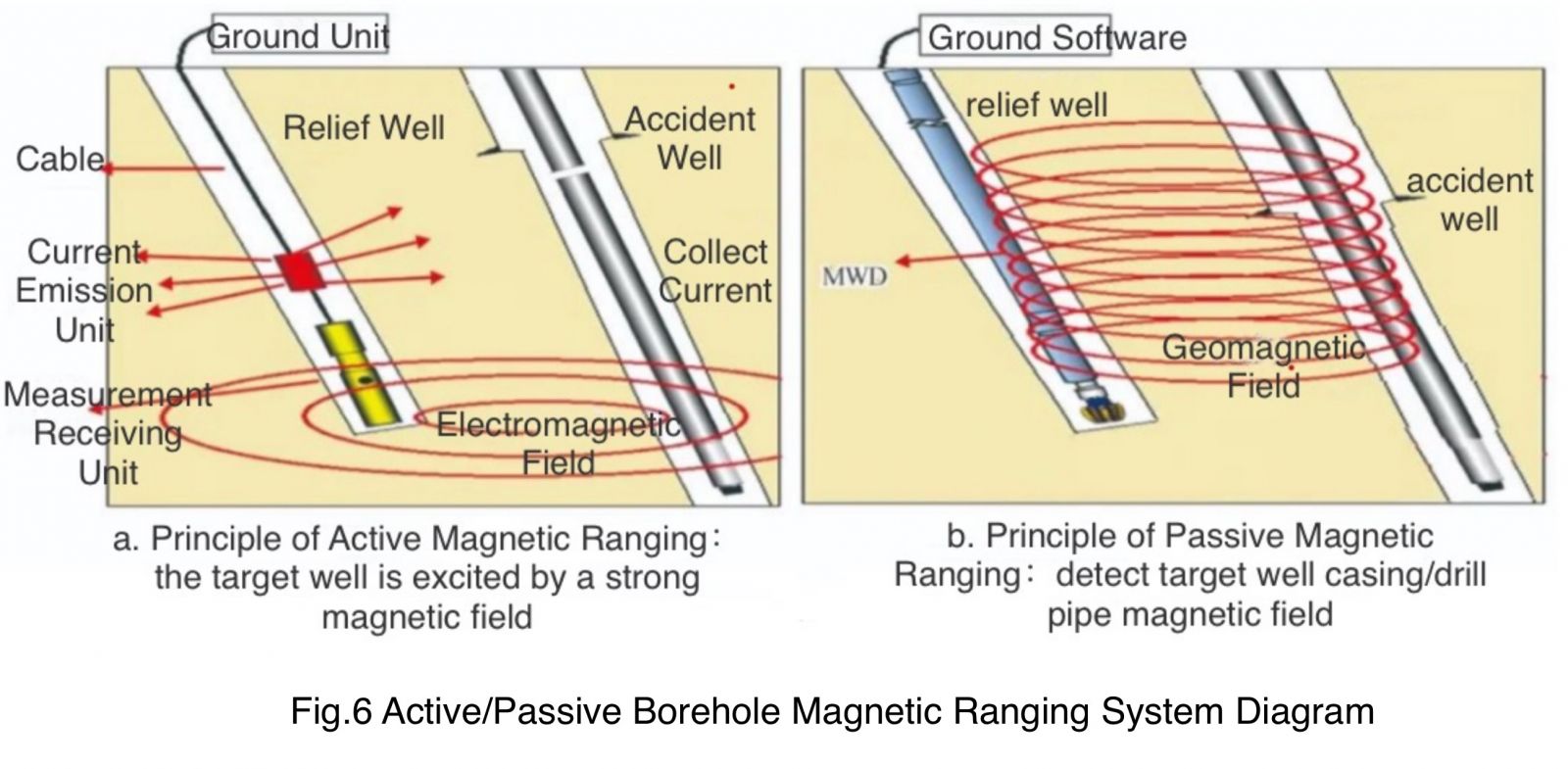

The core technology includes active/passive wellbore magnetic ranging system (Figure 6, Table 2), rescue wellbore trajectory control, connection process and wellbore wall strength calculation, well killing parameter simulation, and other software, such as the rescue well simulation software developed by Schlum Berger company (Figure 7).

Halliburton's rescue well technology has been successfully applied in major blowout accidents such as the Gulf of Mexico and Minneapolis, Texas. In order to improve the rescue well technology series, foreign countries have also developed active/passive acoustic amplitude ranging systems, active resistivity ranging systems, etc. to meet the needs of different drilling fluids and formations.

.jpg)

(Simulation condition: open flow550×104 m3/d +wellhead 24 MPa backpressure+the target well has unobstructed fish and water holes)

The domestic rescue well technology is still in the research and development stage. Academician Gao Deli's team from China University of Petroleum has published 15 SCI papers on wellbore trajectory measurement error analysis, rescue well trajectory design, and rescue well killing simulation calculation. They have obtained 16 authorized invention patents and achieved some theoretical research results. They have developed an industrial prototype of a temperature resistant 125 ℃, high-precision static magnetic (0.1 nT) signal detection and ranging system.

3 .Conclusion and Prospect

Since the "6th Five Year Plan" period, although China has made significant progress in well control technology, there are still technical bottlenecks for the needs of deep and ultra deep oil and gas exploration and high-yield well construction, mainly reflected in the insufficient production needs of carbonate formation pressure prediction theory and early overflow identification technology, and there is a significant gap between visual well killing software and rescue well technology compared to foreign countries. With the continuous expansion of the exploration and development field and the emergence of the "horizontal well+large-scale fracturing development method", drilling with leakage and blowout will become the norm. It is recommended to accelerate the research of well control technology in the following directions:

1) . Conduct in-depth research on the abnormal mechanism of formation pressure in carbonate and igneous gas reservoirs, predict formation pressure, overflow velocity, oil and gas trap volume, and evaluate the impact of multiple factors on well control risks.

2) . Expand new methods for early overflow identification, develop various types of downhole overflow identification sensors, wellbore annular liquid level monitors, and precise flow monitors for drilling fluid inlet and outlet, and improve technical specifications for shallow gas overflow prevention and control. Increase the research and promotion of drilling safety density window expansion technology, study the risk assessment technology for underbalanced well control in high-pressure and low-permeability gas reservoirs based on well testing, form an evaluation software for downward expansion of pressure windows, carry out research on new technologies for constant pressure gradient pressure control drilling that are suitable for horizontal well drilling, expand the hydraulic extension limit of horizontal wells, and form a series of safety density window expansion technologies.

3) . In response to the difficult problem of well killing under complex working conditions, we will strengthen the research on the boundary conditions of well killing, establish a well killing model based on criteria such as bottom hole balance, fastest pressure stability, and maximum bearing capacity of the wellbore. We will develop a dynamic visualization well killing simulation software that dynamically optimizes process parameters based on wellbore defects and converts well killing methods, providing scientific basis and efficient operation support for well killing.

4) . In response to the current situation where well control emergency rescue technology is not suitable for higher pressure levels, higher production rates, and more types of uncontrolled blowout, we are tackling efficient cooling cover, precise continuous cutting, and automatic centering technology for resetting equipment to meet the emergency rescue needs of "three high and one super well" and special wellhead well control. Carry out systematic research on active wireless drilling distance measurement in rescue wells, wellbore trajectory design in rescue wells, target safety control in target wells, well killing simulation, etc., form key equipment and software, and supplement the technical shortcomings of rescue wells.