Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.3 Performance Study of High Efficiency Asphalt Dispersant

2.3.1 Stability

Further investigation was conducted on the long-term unblocking ability of two asphalt dispersants. After reacting at 50℃ for 4 hours, let it stand at room temperature for 24 hours to observe the dissolution of asphalt deposits by two asphalt dispersants. The results are shown in Figure 6.

.png)

After reacting and standing in a dispersant for 24 hours, both LYH-1 and LYH-2 of the asphaltene sediment remained in a well dispersed and dissolved state, and the overall solution in the sample bottle appeared bright black. The inverted LYH-1 sample bottle showed no significant large particle asphaltene deposits, while the bottom of the LYH-2 bottle had some asphaltene deposits, indicating that LYH-1 has better stability than LYH-2 and can better improve the stability of asphaltene and prevent secondary aggregation.

2.3.2 Universality

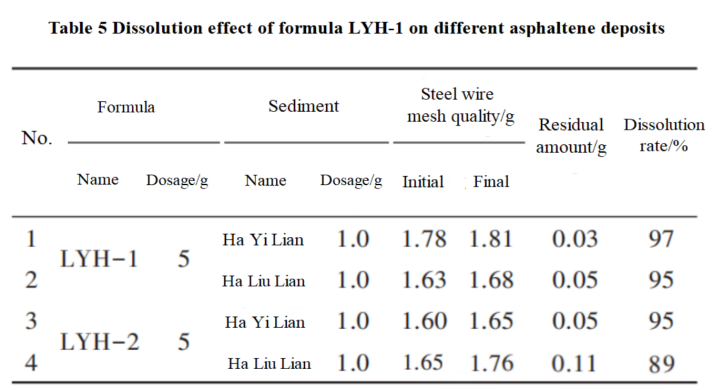

In order to study the universal performance of the formula, two asphalt sediment samples, Ha Yi Lian and Ha Liu Lian, were taken for evaluation experiments. The reaction was allowed to stand at 50℃ for 4 hours, and the experimental results are shown in Table 5 and Figure 7.

.png)

Formula LYH-1 has the best dissolution effect on two types of asphalt deposits under the above conditions, with a dissolution rate of over 95%. Formula LYH-1 can to some extent meet the conditions for conducting plug removal tests in high asphalt content wellbores and can be used for large-scale on-site plug removal operations.

3. Mechanism of action of high-efficiency asphalt dispersant

3.1 Fluorescence spectrum analysis of asphaltene dispersion before and after dispersion

The extracted asphalt was placed under an inverted fluorescence microscope without an eyepiece as the control group. Then, the base solution of LYH-1 formula dissolved asphalt under the optimal reaction temperature and time conditions was uniformly coated on a glass slide to observe the microstructure of asphalt. The results are shown in Figure 8.

.png)

In Figure 8 (a), the distribution of asphaltene before adding solvent is relatively dense, almost occupying the entire microscope field of view. The overall shape and flatness are relatively concentrated and fixed, indicating that asphaltene is a solid with regular shapes. The large specific surface area of crystals is one of the key factors that prevent liquid oil from flowing; In Figure 8 (b), after adding LYH-1, most of the asphaltene was dissolved and dispersed in the solvent, and the overall solution appeared dark gray, with a small amount of undissolved asphaltene particles.From the perspective of dissolution equilibrium, during the precipitation process of asphaltene, the aromatic nuclei in asphaltene tend to aggregate and stack with each other through intermolecular van der Waals forces or polar interactions, resulting in a decrease in its solubility in solvents; The main component of LYH-1 is a high state aromatic solvent, and the additive also contains sulfonic acid groups, which can penetrate and disperse into small molecules of resin and asphaltene through hydrogen bonding, and locally fold and stack them up, resulting in a loose structure, reduced spatial orderliness and extensibility, thereby enhancing the solubility of asphaltene in the solvent.

3.2 Effect of Formula on Asphalt Plasmid Size Distribution

React at 50℃ for 4 hours, change the amount of LYH-1 solvent added, dilute the mixed solution with pure water 50 times and titrate it in a laser particle size analyzer until the concentration is normal. Then collect data, as shown in Figure 9.

.png)

With the increase of LYH-1 dosage, the particle size of asphalt particles becomes smaller and smaller, indicating that LYH-1 can effectively suppress the aggregation of asphalt. Less solvent usage and wider particle size distribution; As the solvent dosage increases, the particle size distribution gradually narrows. When the dosage of LYH-1 is 15 g, it can disperse asphaltene into smaller particles with an average particle size of 2.53 nm. Based on colloid theory and the binding effect of asphaltene, it is believed that LYH-1 has a stable steric hindrance between itself and asphaltene, which hinders the binding of asphaltene molecules, reduces the size of asphaltene, and effectively inhibits the aggregation and precipitation of asphaltene.

4 . Conclusions

This article establishes a new method for rapidly and accurately evaluating the performance of asphalt dispersants on oilfield sites. By analyzing high asphalt content sediments, targeted optimization of asphalt dispersants and additives is carried out for formulation, and the dissolution effect is evaluated. Finally, the following conclusions are drawn through the study of the mechanism of action.

1).Through the analysis of three components and elemental composition of asphaltene sediment, it is known that the asphaltene content in the sediment of Tahe wellbore is as high as 40.5%, and the wax content is 1.07%. The sediment has a high content of heteroatoms and a low H/C ratio, indicating a high degree of condensation and a high degree of unsaturation in structures such as cyclic and aromatic rings.

2).By selecting a single solvent, compounding and optimizing a combination of main solvent, surfactant, and co solvent with good asphalt solubility. According to the experimental results, the final formula LYH-1 was determined, and its highest dissolution rate reached 97% after 4 hours of constant temperature reaction at 50 ℃. Stability and universality studies have shown that LYH-1 can stably disperse and dissolve asphaltene sediments for a long time, achieving good dispersion and dissolution effects on sediments from different oil layers.

3).By observing the microstructure of asphaltene before and after solvent addition using an inverted fluorescence microscope without an eyepiece, it was found that the original regular and dense structure of asphaltene was disrupted. LYH-1 mainly prevents the binding of asphaltene molecules through hydrogen bonding and π - π interactions. The particle size distribution of asphalt particles under different dosages of LYH-1 was measured using a laser particle size analyzer. As the dosage of LYH-1 increased, the particle size distribution became narrower and the particle size of agglomerated asphalt particles significantly decreased. LYH-1 high-efficiency asphalt dispersant has good application prospects in the operation of plugging in heavy oil reservoirs.