Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.1.2 Early overflow monitoring technology

Formation pressure prediction technology is a direct means to prevent blowout, but currently various formation pressure prediction technologies are difficult to meet the needs. The drilling formation testing (DFT) project team of Pathfinder Energy Services has successfully developed a while drilling formation testing system (FTWD) that inserts quartz pressure gauges into the wellbore for pressure measurement; Schlumberger pioneered the StethoScope while drilling formation pressure tester, which combines its MDT technology with LWD. It began commercial service in January 2005, but did not receive widespread promotion. Therefore, on-site monitoring of formation pressure is generally changed to overflow monitoring.

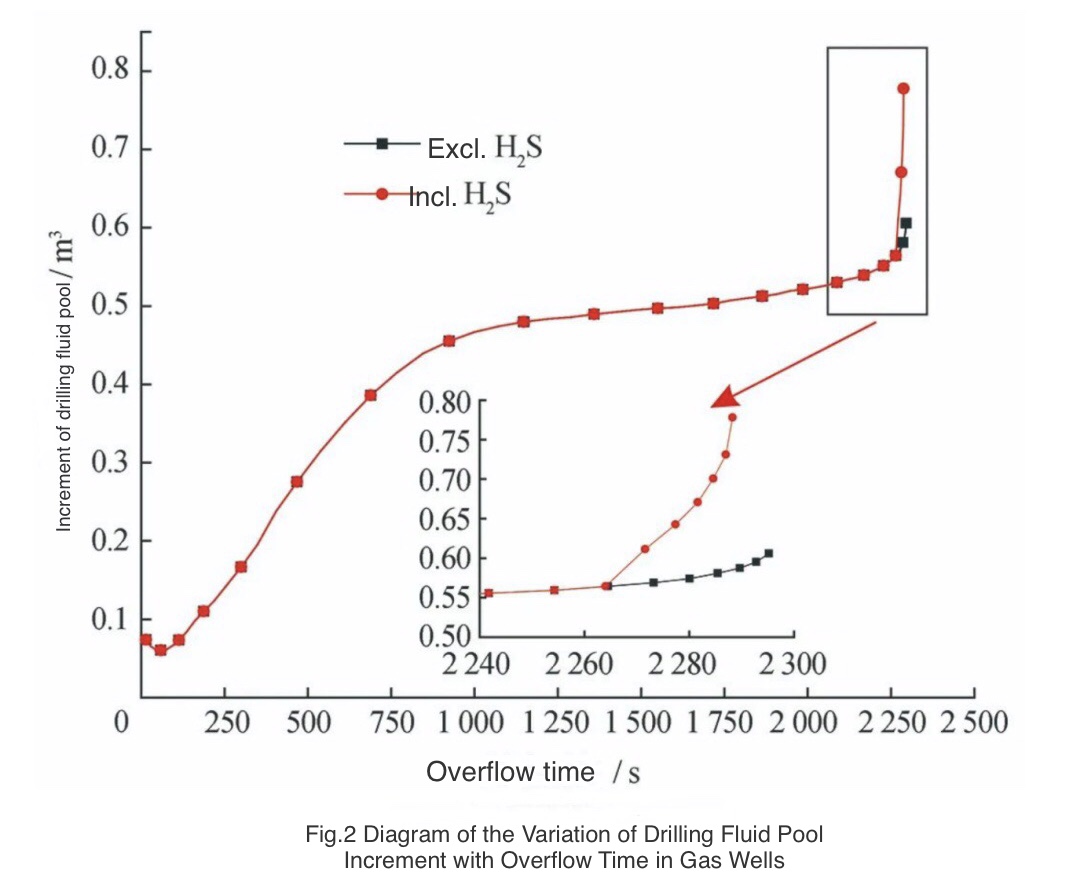

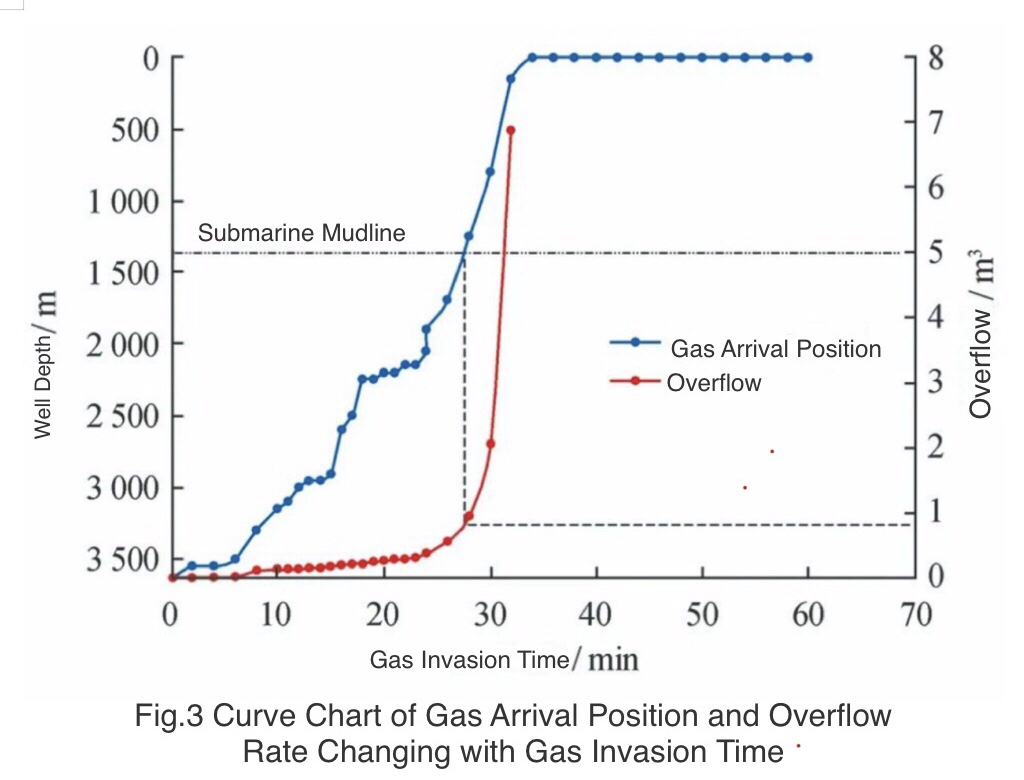

Most overflow monitoring is designed based on the mechanism of volume expansion during the upward flow of underground formation fluids, due to the significant expansion of the fluid volume invading the wellbore, it needs to wait until it reaches the shallower wellbore section before conventional circulating tank liquid level monitoring methods can detect it. The oil and gas drilling industry has developed a working mechanism of early detection and early control to prevent gas invasion and overflow from evolving into blowout. According to the industry regulation of 1 m3 alarm, the overflow at a depth of 3000 meters can only be detected after 30 minutes, and the alarm can only be issued when the overflow has reached a depth of 1000 meters (Figure 2, 3). The circulating tank liquid level monitoring method has the drawbacks of slow detection and easy misreporting.

Therefore, Li Yufei et al. proposed an early overflow identification method based on SVM and D-S evidence theory, which reduces identification errors and false positives by collecting more parameters such as outlet flow rate, wellbore annular pressure, temperature, standing pressure, and hook load for comprehensive overflow identification. Weatherford directly achieved early overflow identification in its controlled pressure drilling system through high-precision mass flow meters on the ground.

In addition, if the overflow monitoring is transferred from the ground to the underground, the underground gas invasion and overflow situation can be monitored in the first time. The most researched product at home and abroad is PWD, which helps identify overflow through bottomhole pressure and temperature assistance. Chuanqing Drilling Company, in collaboration with universities such as China University of Petroleum (Beijing), has explored a method for identifying early underground overflow based on the dielectric properties of near drill fluid and ultrasonic Doppler effect. The early overflow identification method based on the dielectric properties of drilling fluids is based on the principle that the dielectric constant of different fluids is different, and the identification of overflow is achieved by monitoring the changes in the dielectric constant of gas invasion drilling fluid components that will cause changes in their dielectric constant; The early overflow identification method based on ultrasonic Doppler utilizes the principle of rapid attenuation of ultrasonic Doppler signals in gas-bearing drilling fluids to achieve overflow identification, When the gas content of the drilling fluid is greater than 1.5%, the signal will rapidly decay. When the gas content reaches about 5%, the signal decay rate is between 60% to 80%. After developing the corresponding near drill bit sensor, the overflow signal is uploaded to the ground through MWD, and the overflow warning time can be controlled within 10 minutes.

2.1.3 Fine Pressure Control Drilling Technology

Pressure balanced drilling is the key to well control technology. In the past, only static emphasis was placed on the balance between formation pressure gradient and drilling fluid density. Dynamic changes in wellbore pressure such as ECD, excitation pressure, and suction pressure were simply added to the drilling fluid density. In actual drilling processes, changes in bottom hole pressure caused by changes in operating conditions are variable, and drilling with drilling fluid with added density still carries the risk of blowout. Deep oil and gas reservoirs often have better quality, and high-temperature, high-pressure, high-yield, and sulfur-containing reservoirs with excellent permeability often exhibit narrow safety density windows, which can easily lead to complex well control problems such as leakage and simultaneous storage.

Fine pressure control drilling technology is a new technology that utilizes appropriate ground control measures to control the bottom hole pressure (and even the annular pressure profile) and maintain a constant dynamic wellbore pressure under conditions such as tripping and circulating drilling fluid. This technology achieves a dynamic and precise balance between wellbore pressure and formation pressure, eliminating the occurrence and conversion of leakage and blowout caused by bottom hole pressure fluctuations. In 2005, ENI Company first successfully achieved commercial application, and later MPO Company in the United States developed a continuous circulation drilling system with a circulation valve.

Weatherford has developed a precision controlled pressure drilling system, which can detect overflow when the inflow is less than 80 L using micro flow control technology (MFC), and quickly control the overflow (less than 2 minutes) when the total overflow volume of the formation fluid is less than 800 L.

The Halliburton controlled pressure drilling system measures the bottom hole pressure in real-time through PWD, uses high-precision hydraulic models to design drilling fluid density and related control parameters, and uses throttle valves and backpressure pumps to control backpressure to achieve constant bottom hole pressure drilling.

Schlumberger has developed a drilling optimization system characterized by Dynamic Annular Pressure Control (DAPC), which integrates multiple algorithms to achieve annular pressure monitoring, wellbore stability monitoring, and leakage monitoring.

On the basis of digesting and absorbing foreign technologies, China has developed fine pressure control drilling systems such as PCDS-I, CQMPD-I, and CQMPD-II, which are widely used in deep and horizontal wells in Tarim, Jidong, and Southwest oil and gas fields. Based on different geological conditions and formation fluid types, various process methods such as micro leakage, micro underflow, mud cap, and plugging to improve pressure bearing capacity have been standardized, greatly reducing complex time and well control risks. For example, the popularization rate of this technology in the Dengying Formation drilling of the Gaoshiti Moxi block in the Southwest Oil and Gas Field has reached 100%, reducing the leakage rate by 87.8% compared to conventional drilling, and basically eliminating the overflow treatment time.

2.2 Secondary Well Control Technology

2.2.1 Well Control Equipment

The iconic achievements of the drilling industry during the "6th Five Year Plan" period are well control equipment and a series of well control operation standards. The core equipment includes blowout preventers, internal blowout prevention tools, choke manifolds, and their control devices, which are important tools to prevent overflow from deteriorating into blowout. China Petroleum's well control equipment technology has been continuously developing, and has developed a driller's room shut-in control console, wireless remote control shut-in device, wellhead automatic misoperation prevention device, and well control training simulator. It is equipped with a 70/105/140 MPa high-pressure series sulfur resistant wellhead device, well control manifold, pneumatic weighting system, and automatic blowout ignition device that is suitable for the formation pressure level; In terms of pressure level, a full range of matching has been achieved, and the control method has achieved remote and fast control, gradually developing towards multi point and one click operation. Establish regional emergency well killing material storage bases as needed in high-risk areas for well control, providing security for deep and ultra deep well control.

2.2.2 Kill Technology

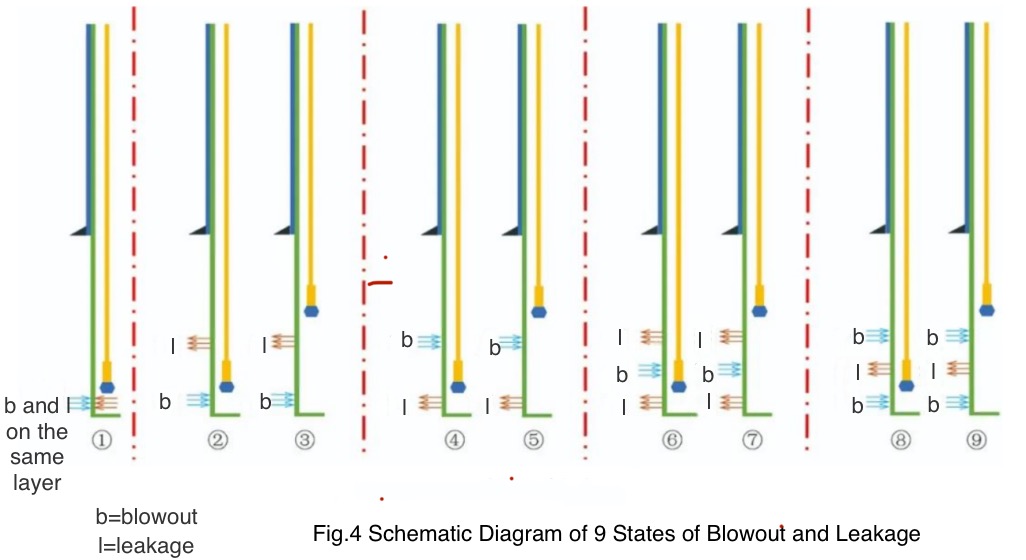

From Jurassic to Sinian, there are 27 sets of oil and gas reservoirs vertically distributed in the Sichuan Basin, and most of the carbonate rocks are acidic gases; The Tarim Basin is characterized by high temperature, high pressure and high production, and the pressure systems of sub salt reservoirs drilled are very different. The drilling of 8000 m ultra deep wells often has multiple pressure systems with significant differences in the same open hole, and even a single production layer does not have a safety density window. Overflow disposal is often accompanied by upper and lower leakage, upper and lower leakage, and the same layer of leakage. Well control technology has been developed through extensive practice, even at the cost of blood, and the drilling and engineering methods for well killing have been gradually improved and developed. Overflow discovered too late will cause excessive wellhead pressure, which may exceed the control capacity of the wellhead. High casing pressure conditions can cause well leakage or even underground blowout during well shut-in and killing processes, and may also cause uncontrollable leaks, explosions, or equipment fires at the wellhead, pipelines, and casing, resulting in failed well killing. Killing a well with both leakage and blowout is a great challenge, and unconventional well killing techniques are usually used to solve the contradiction between blowout and leakage. Blowout control is the key, and leakage control must be carried out in parallel, and both must be taken into account in the treatment. Its underground working conditions are complex and diverse (Figure 4), and through extensive practice, targeted well killing techniques have been formed, such as gas well leakage lifting and grouting technology, positive circulation plugging and well killing technology, reverse circulation plugging and well killing technology, annular reverse squeezing plugging and well killing technology, cement slurry plugging and well killing technology, and rapid drying cement dynamic plugging and well killing technology. Multiple well control hazards in Sichuan, Xinjiang, Qinghai, and other places have been successfully dealt with.

Unconventional well killing also includes special well killing methods that are used when conventional well control methods cannot be used in the event of severe blowout or special wellbore conditions, such as well blowout, toxic gases such as high sulfur content in the well, drilling tools being far from the bottom of the well during well killing, channel blockage in the drilling tools, or drilling tools being punctured and broken in shallow areas. Unconventional well killing mainly includes four process methods: displacement method (also known as volume method), back pressure method (also known as hard top method, horizontal push method, reverse push method), top well killing method (also known as momentum well killing method), and dynamic well killing method. Scholars at home and abroad have conducted long-term research and practice. In 2017, SXX well lost circulation when drilling to a depth of 5451 meters, and overflowed when tripping out to a depth of 5352 meters. The shut-in casing pressure was 40 MPa, and the downhole conditions were variable. After positive circulation well killing and reverse thrust well killing, the downhole drilling tools were blocked, and the casing pressure continued to rise to 58 MPa. After blowout and pressure reduction, 185 m3 of high-density drilling fluid was injected forward for the third time, and the second reverse thrust method was prepared to kill the well. The test shut-in casing pressure increased from 30 MPa to 50 MPa within 4 minutes. The fourth time, rapid drying cement slurry was used to dynamically seal and kill the well to relieve the risk of blowout.

2.2.3 Security Density Window Expansion Technology

Deep well drilling often encounters multiple pressure systems or fractured gas reservoirs without a safe density window, and the ECD difference in small wellbore horizontal wells breaks through the safe density window. Even with the use of fine pressure control drilling technology, there are many difficulties, and there is an urgent need for safe density window expansion technology. Kang Yili and others proposed five technical approaches to expand the safety density window from the perspectives of physics, chemistry, and mechanics. The basic principle is to increase the leakage pressure of the formation by sealing weak formations with defects.

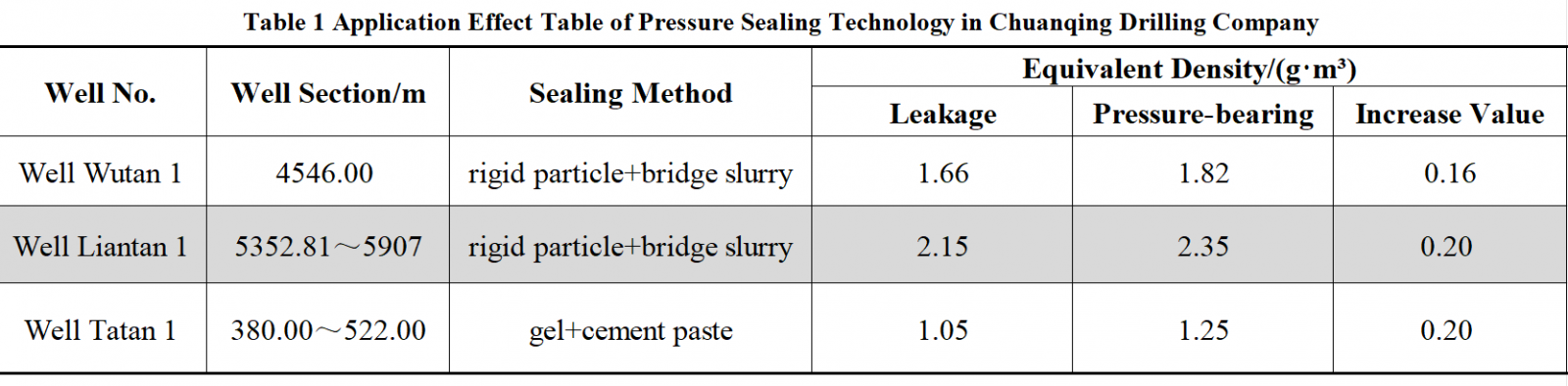

Chuanqing Drilling Company has developed a multi action temperature controlled plugging agent with rigid particle bridging, soft rubber plug filling, and temperature activated cementation, as well as its pressure bearing plugging process. Experiments have been conducted in ultra deep wells such as Wutan 1, Liantan 1, and Tatan 1, and the success rate of plugging has been increased by 20%. The formation pressure difference has been increased to 10-20 MPa (Table 1), providing a guarantee for the safety of drilling in windowless sections.