Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

At present, oil and gas exploration and development are making significant progress in areas such as ultra deep and unconventional formations. Drilling well control faces a series of safety challenges such as low prediction accuracy of special lithology formation pressure, complex multi production layer and multi pressure system, narrow safety density window of main production layers, and oil and gas leakage at the wellhead of old wells. In order to ensure the steady progress of oil and gas exploration and development, based on domestic and international well control technology research and international benchmarking analysis, a systematic analysis was conducted on the challenges, research progress, and development direction of well control technology. The research results indicate that:

①. prediction/detection of formation pressure in carbonate reservoirs, exploration of early overflow monitoring, and promotion and application of pressure control drilling technology, with the continuous development of primary well control technology;

②. A secondary well control technology has been formed, mainly focusing on "well control equipment, unconventional well killing, and expansion of safety density window", which basically ensures the safe operation of multi production layer and multi pressure system wells;

③. Proposed a new concept of rescue for uncontrolled well blowout during the entire process of hot work, and formed a self owned intellectual property rights rescue technology for uncontrolled and high-yield wells in acidic oil and gas reservoirs;

④. We have developed a static magnetic ranging system while drilling, and the rescue well technology has a theoretical foundation and the conditions for production application.

The conclusion is that although significant progress has been made in domestic well control technology, continuous research is still needed in the fields of special oil and gas reservoir formation pressure prediction theory, unconventional well killing technology, and rescue well technology to meet the development needs of ultra deep and unconventional oil and gas fields.

Introduction

Since the 13th Five Year Plan period, China National Petroleum Corporation (CNPC) has implemented a strategic layout of "deepening the eastern region, accelerating the western region, placing equal emphasis on oil and gas, and promoting both regular and non regular development". Oil and gas development has blossomed in areas such as deep carbonate, tight sandstone, and shale, achieving significant results in increasing reserves and production. Especially deep carbonate reservoirs have enormous resource potential and have become a key area for future oil and gas exploration and development. In recent years, China has successively discovered and explored a number of deep carbonate oil and gas fields such as Anyue, Puguang, Yuanba, Tazhong, and Kuche. Ultra deep well drilling has entered the 8000 meter era, but the well control situation is becoming increasingly severe.According to statistics, from 2019 to 2020, there were a total of 58 overflow warnings and 11 cases of high casing pressure during deep well drilling in Southwest Oil and Gas Field; Shallow well bursts caused by fracturing interference in Tarim Oilfield, Qinghai Oilfield, and Eastern Oilfield are showing a high incidence trend. Data shows that high pressure, high production, high sulfur content, ultra deep wells (hereinafter referred to as "three highs and one super"), horizontal wells, and shallow gas are high-risk areas for well control, and well control technology is facing new challenges. Once a well control accident occurs in oil and gas drilling, it will have an extremely serious negative impact on the corporate image, bringing huge disasters and losses to society and the environment.

1. Challenges and Cause Analysis of Well Control Technology

The challenges faced by well control technology are mainly reflected in the complexity of the drilled formations, changes in well types, and changes in operating methods, leading to a gradual increase in risks such as overflow and blowout during the drilling process. The main performance is as follows:

①. Drilling engineering is gradually advancing towards the "three high and one super" wells, and frequent oil and gas displays are becoming increasingly normalized. The exploration and development in areas such as Sichuan Chongqing, Xinjiang, and Qinghai continue to extend to deep strata, with a rapid increase in the number of deep and ultra deep wells. The geological engineering conditions are becoming increasingly complex, and the well structure is difficult to meet the needs;

②. Narrow safety density windows during the drilling process bring new well control risks. On the one hand, deep oil and gas reservoirs generally contain natural gas, with more developed fractures and caves, resulting in reservoir sensitivity to pressure and narrow density windows for safe drilling; At the same time, various types of oil and gas resource development wells basically adopt high inclination wells and horizontal wells. As the well section in the reservoir extends, the contact surface between the wellbore and the reservoir expands, the ECD difference increases, and pressure sensitivity issues become prominent, which is easily leading to complex and dangerous situations where spills and leaks coexist.

③. Occasional shallow gas can quickly lead to blowout accidents, especially wellbore integrity defects after high-strength stimulation measures, causing abnormal high pressure traps due to upward migration of formation pressure. During drilling, well control battles often occur in the upper formation. According to statistics, shallow blowout accounts for up to 80% of blowout accidents that have occurred in the past 20 years. Faced with new formations, new well types, and new operating methods, well control technology has also shown many maladaptability.

1.1 Immature prediction technology for carbonate formation pressure, low accuracy and difficulty in pressure prediction

According to incomplete statistics, blowout warnings caused by inaccurate prediction of formation pressure account for about 60% of the total number of warnings, ranking first in frequency. At present, a series of research results have been achieved in pressure prediction for sedimentary formations such as sandstone and mudstone profiles both domestically and internationally. However, the limitations of technical application are extremely strong. For carbonate gas reservoirs characterized by low permeability, heterogeneity, developed fractures, and high structural stress, the formation high-pressure genesis is complex and the rules are unclear. For a long time, the theory of formation pressure prediction has not been broken through.The maximum difference between the actual drilling fluid density and the design is 0.50 g/cm3 in the Jialingjiang Formation and Qixia Formation of a certain well in Longgang North, Southwest Oil and Gas Field; The error between predicted pressure coefficient and actual drilling of 8 drilled wells in the southern margin of the Junggar Basin is between 12% and 58%.

1.2 Deep gas reservoirs face multiple production layers and pressure systems, with insufficient wellbore structure

Deep gas reservoirs are limited by the hierarchical structure of the wellbore, with multiple pressure systems coexisting in the same open hole section. During the drilling process, it is easy to experience up and down leakage or up and down leakage. 27 sets of gas and water display layers have been discovered vertically in the northwest of Sichuan Basin, with significant differences in pressure systems (pressure coefficients ranging from 1.07 to 2.30). When encountering multiple pressure systems during drilling in the same open hole section, it is difficult to balance overflow and leakage. Taking Longtan 1 well in the Southwest Oil and Gas Field as an example, the well design adopts a non-standard wellbore structure with seven openings. After encountering a high-pressure saline layer in the Jia 2 section, a Ø219.08 mm casing was forced to be drilled in advance, and the Feixianguan Liangshan Formation was forced to be drilled together in an open hole section, resulting in interweaving of downhole overflow, leakage, and jamming. The Kuqa foreland basin in the Tarim Basin is characterized by ultra deep, ultra-high pressure, high temperature and complex longitudinal lithology. The development of three non-standard well bore structures, including tower standard I, tower standard II and tower standard III, still cannot meet the needs.

1.3 Fractured gas reservoirs and horizontal wells pose increasingly prominent issues with limited safety density windows

Not only are deep and high-quality oil and gas reservoirs sensitive to pressure, but they exhibit a narrow safety density window phenomenon. During the development of horizontal wells, the difference in ECD increases due to small wellbore and rock debris bed. During the drilling of long horizontal sections, overflow and leakage occur simultaneously, often leading to a passive situation of well leakage inducing overflow or both spraying and leakage. According to the statistics of CNPC Chuanqing Drilling Engineering Co., Ltd. (hereinafter referred to as Chuanqing Drilling Company), 24% of the production layer overflow warning is caused by leakage to overflow. In addition, low permeability and unconventional resources also experience overflow caused by fracturing interference.

1.4 Complex lithology wellbore instability leads to complex three pressure profiles and difficult wellbore pressure control

Taking Well Datan 1 of Southwest Oil and Gas Field as an example, the clay mineral content in the upper low-pressure layer is high. There are high-pressure saline layers in the Leikoupo Formation and Jialingjiang Formation, and complex rock layers and display layers such as basalt in the middle require high-density drilling fluid. The three pressure profiles are interwoven. The basalt section used 2.03 g/cm3 drilling fluid for malignant leakage, and the density decreased to 1.87-1.93 g/cm3 to stop leakage and serious collapse; The density of the drilling fluid in the Maokou Formation was severely collapsed between 1.29 and 1.50 g/cm3, exacerbating the leakage to 1.81 g/cm3 and decreasing to 1.77 g/cm3. After drilling, the gas logging was abnormal.

In addition, some oil and gas fields have been exploited for many years, and a large number of production wells have failed to seal the gate valves at the wellhead, causing oil and gas leakage due to corrosion and perforation. The pressure inside the wells is unknown, posing significant well control and environmental risks. Some wells are located in densely populated areas, which have an impact on the surrounding environment and resources. It is estimated that nearly 100 old wells in oil and gas areas such as Sichuan Chongqing and Changqing need to undergo pressure replacement of pipe columns, gate valves, or gas production trees every year, requiring advanced well control technology to ensure safe operations.

2. New progress in well control technology research

In order to ensure the smooth progress of oil and gas exploration and development, domestic and foreign well control technologies have made significant progress in carbonate formation pressure prediction, early overflow detection, fine pressure control drilling, expansion of safety density window, full process fire operation, rescue wells, and other aspects. From primary well control to rescue of uncontrolled blowout wells, significant progress has been made in theory, equipment, and process technology. A complete well control service industry chain has basically formed in foreign countries.

2.1 Primary Well Control Technology

2.1.1 Exploration of Carbonate Formation Pressure Prediction Technology

The method for calculating formation pore pressure based on the theory of shale undercompaction has a high degree of consistency in drilling sedimentary sand and mudstone. With the exploration and development of marine carbonate rocks in the south and west of China, as well as ancient buried hills and igneous rocks in the east, the method for predicting formation pressure using the theory of undercompaction is no longer applicable. Because there are many influencing factors and complex causes of abnormal pressure in carbonate rock formations, mainly including undercompaction, hydrocarbon generation, thermal cracking of liquid hydrocarbons, tectonic compression, conversion of montmorillonite to illite, and hydrothermal pressurization. Carbonate rocks have the characteristics of dense matrix and strong rock skeleton stiffness. Abnormal high pressure exists in randomly developed heterogeneous pores and fractures, and relying on pressure prediction models to deduce continuous carbonate formation pressure profiles does not match the actual situation.

Terzaghi and Biot et al. first proposed the effective stress theorem method, which has important reference value for improving the accuracy of carbonate rock formation pressure prediction. However, they are based on the relationship between rock strain and stress while maintaining constant pore pressure, and cannot explain the mechanical mechanism of saturated rock pore pressure increasing with increasing confining pressure, Therefore, the prediction technology of carbonate formation pressure is still a world-class challenge, and domestic scholars have also conducted beneficial explorations.

Based on the thin plate theory, Yu Fu et al. proposed a new mechanism for the formation of abnormal high pressure in carbonate rocks by considering the degree of compression of geological structures, the connectivity of fault outcrops, and the volume elastic modulus, established a geological mechanical identification model for formation pressure considering structural compression factors. By substituting geometric and mechanical parameters of geological structures, as well as in-situ stress, density, longitudinal and transverse wave velocity, porosity, etc., into the model, the formation pressure coefficient can be obtained. In the Y oilfield of the Persian Gulf Basin, the relative error between the predicted value and the measured value of the SFT (cable type formation tester) is less than 10%.

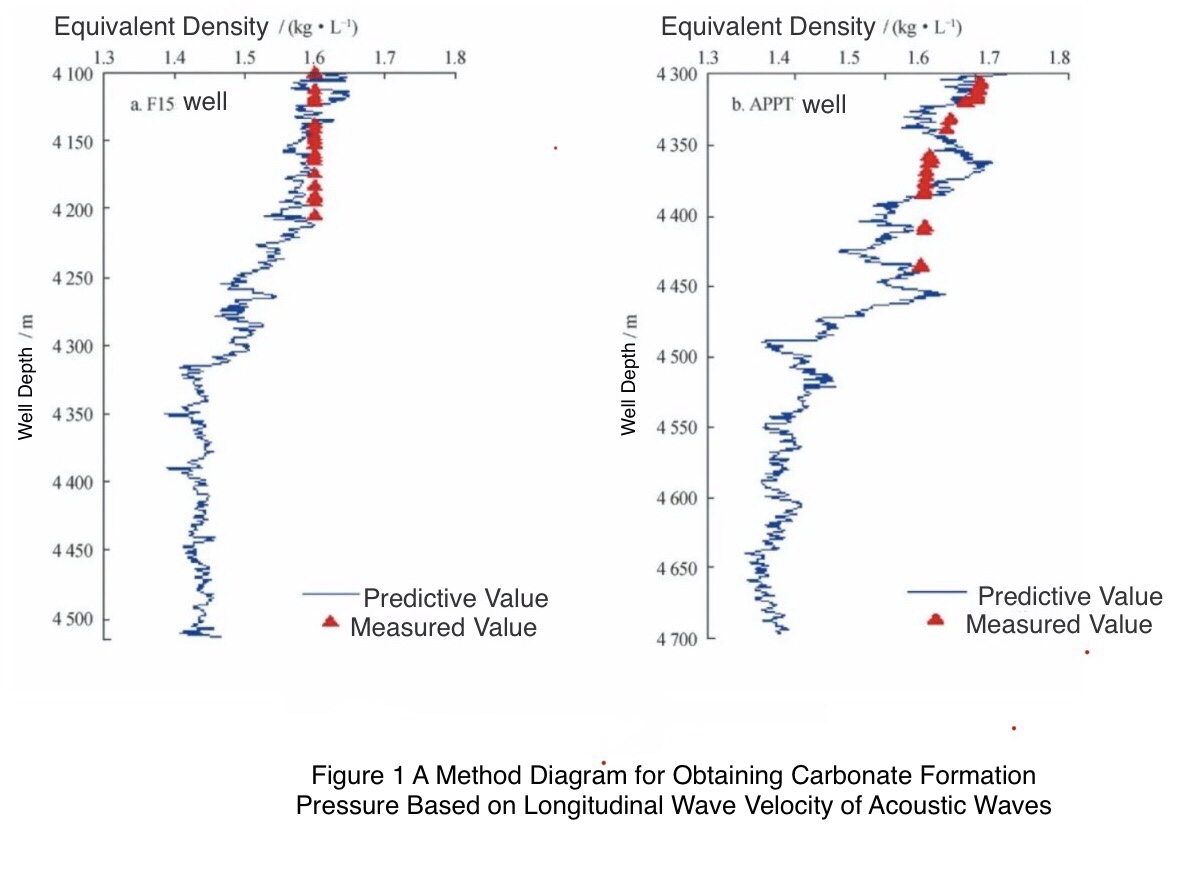

Lu Baoping's research found that the changes in longitudinal wave velocity of carbonate rocks under different pore pressures are mainly caused by the changes in longitudinal wave velocity of pore fluids. The wavelet transform method was used to extract and amplify the impact of small fluctuations in longitudinal wave velocity of pore fluids on the longitudinal wave velocity of rocks. The abnormal pressure layer of carbonate rock formations was determined, and a prediction model for carbonate rock formation pore pressure was established by combining it with measured formation pore pressure data, A method was proposed to predict carbonate formation pressure by extracting the longitudinal wave velocity of fluids in formation pores. Preliminary verification through on-site application: the error between the calculated equivalent density of formation pore pressure and the measured value is less than 15% (Figure 1). But many aspects require subjective inference, and there is still no breakthrough in quantitative prediction technology.