Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

.png)

Lost circulation is a common underground complex problem in drilling engineering, which seriously affects drilling construction safety and drilling cycle. Fine identification of lost circulation characteristics is the key to efficient management of lost circulation. Firstly, by integrating logging, drilling, logging, and geological data, combined with the analysis of mechanical properties and physical mechanisms of lost circulation layers, a new method for identifying lost circulation layers based on the "comprehensive index of lost circulation" was established using the weighted coefficient method. Then, a quantitative analysis method for well leakage characteristic parameters such as leakage channel types and sizes, leakage pressure difference, and leakage velocity was studied, and a calculation model was provided to form a multi information fusion method for fine identification of well leakage characteristics. This method was analyzed as an example in Block X, and the analysis results showed that the processing results of actual well data in Block X were basically consistent with the actual leakage characteristics such as the stratigraphic position, leakage type, and leakage speed of the lost formation on site. The fine identification method for well leakage characteristics comprehensively considers the main influencing factors of well leakage, and can accurately identify the characteristics of the leakage layer, providing scientific basis for the optimization and construction of leak prevention and plugging technology.

During the drilling and completion process of high permeability fractured and fractured formations, the leakage is severe and the success rate of plugging is low. Establishing a method for identifying leakage characteristics is the key to preventing and controlling leakage, and it is also a current research hotspot. According to the mechanism and causes of leakage, well leakage can be divided into permeable leakage, fractured leakage, and karst leakage. Among them, fractured leakage includes natural fracture leakage and induced fracture leakage. Leakage pressure difference is a key parameter for analyzing the characteristics of well leakage. Shilin et al. proposed a model of minimal formation leakage pressure and provided the relationship between leakage pressure difference and formation pore pressure and fracture pressure. Domestic and foreign experts and scholars have different opinions on the leakage pressure difference, and the proposed models also vary. It is necessary to choose a suitable model based on actual geological engineering conditions to determine the leakage pressure difference. With the continuous deepening of exploration and development, the problem of well leakage in major domestic oil fields is becoming increasingly prominent, and the methods for determining the location of well leakage layers are also constantly developing. Gan Xiu'e et al. proposed a method to determine the lost layer by utilizing the logging response characteristics of the lost layer based on the analysis of conventional logging and imaging logging data. Drilling engineering data is also widely used to determine the location of lost circulation layers. Chen Ganghua et al., based on the traditional vertical pressure change testing method, introduced wellbore logging curves and segmented calculations based on drilling tool combinations and wellbore structures, making the vertical pressure change testing method more perfect and more accurate in determining the location of lost circulation layers.

At present, multiple experts have conducted theoretical research and practical application exploration on the identification method of well leakage characteristics, and have made progress in the classification of leakage types, calculation of leakage pressure, and determination of leakage layers. However, at present, the identification of well leakage characteristics at home and abroad is generally limited to a single or partial information data, without comprehensively analyzing the main influencing factors of well leakage from multiple perspectives, lacking quantitative analysis of the main characteristic parameters of well leakage, and difficult to comprehensively and finely reflect the characteristics of well leakage. Therefore, this article comprehensively utilizes logging, drilling and geological data to establish a quantitative analysis model that considers the main characteristic parameters of well leakage, such as the location of the leakage layer, the type and size of the leakage channel, the leakage pressure difference, and the leakage velocity. A fine identification method for well leakage characteristics is formed, which improves the accuracy of well leakage identification and provides a scientific basis for optimizing leak prevention and plugging technology.

1.Basic Principle of Well Leakage Feature Recognition based on Multi Information Fusion

Lost circulation is a common and complex downhole situation that can occur in various formations during the drilling process. Given the limitations of current domestic and foreign methods for identifying well leakage features, a multi information fusion method for fine identification of well leakage features has been proposed. This method fully utilizes multi information and multi parameter data, and integrates logging, drilling and geological data to establish an analysis model for key parameters such as leakage layer, leakage channel type and size, leakage pressure difference, and leakage velocity, in order to comprehensively refine the characterization of well leakage characteristics.

Firstly, based on the basic conditions for the occurrence of lost circulation, combined with the mechanical properties and physical mechanisms of the lost circulation layer, a new method for identifying the lost circulation layer based on the "comprehensive index of lost circulation" was established. Based on the characteristics of permeability leakage, the average pore throat radius was determined by analyzing physical properties parameters, and the parameters of permeability well leakage channels were obtained; For fractured leaks, use deep and shallow lateral resistivity logging data to calculate the crack opening and determine the size of the lost crack. The formation pore pressure, formation fracture pressure, and wellbore pressure jointly determine the magnitude of the leakage pressure difference. If there is an original leakage channel in the formation, the leakage pressure difference is mainly the difference between wellbore pressure and formation pore pressure (pressure difference leakage); If it is an induced fractured leakage channel, the leakage pressure difference is mainly the difference between wellbore pressure and formation fracture pressure (fracturing leakage). Then, based on the analysis results of well leakage characteristic parameters such as leakage layer, leakage channel type and size, leakage pressure difference and leakage velocity, a multi information fusion method for fine identification of well leakage characteristics was formed.

2.Analysis of Characteristic Parameters of Well Leakage

Block X is a fault nose structure with 4 developed faults. The structure is confirmed, but it is relatively close to the fault. During the actual drilling process, the situation of well leakage is increasing day by day, and it is difficult to plug the leakage, resulting in a large amount of drilling fluid leakage, seriously affecting normal construction. According to incomplete statistics, 14 wells with water-based drilling fluid lost a total of 1758.3m3, and 13 wells with oil-based drilling fluid lost a total of 2035.60m3. Accurately locating the lost circulation layer is the key to the success of plugging operations.

2.1 Analysis of Lost Circulation Horizons

Based on the basic conditions for well leakage, the correlation between the positive pressure difference on both sides of the wellbore, rock porosity, permeability, and the leakage layer was analyzed, as shown in Figure 1. From Figure 1, it can be seen that the positive pressure difference on both sides of the wellbore in the leaking layer is slightly higher than that of the non leaking layer, and the physical properties of the leaking layer are better. The difference between the two is more obvious in terms of positive pressure difference on both sides of the wellbore, but not in terms of physical properties, indicating that the positive pressure difference on both sides of the wellbore in Block X has a significant impact on wellbore leakage.

.png)

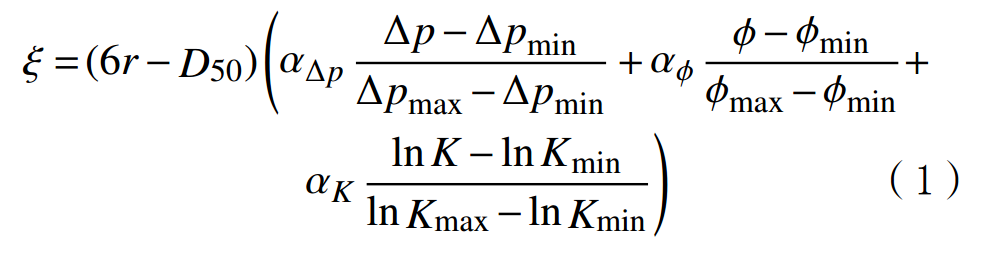

Based on the above analysis results, taking into account the mechanical properties such as formation pore pressure, formation fracture pressure, and wellbore pressure, as well as the physical properties such as rock porosity, permeability, and average pore throat radius, a new method using weighted coefficient method to calculate the "comprehensive index of well leakage" and determine the location of well leakage layers was established by analyzing the data of lost wells in Block X. Permeable formations with large positive pressure differences and good physical properties on both sides of the wellbore are prone to well leakage. Therefore, the empirical formula for the comprehensive index of well leakage in permeable formations is:

In the formula:ξ is the comprehensive index of well leakage;r is the average pore throat radius of the formation,μm;D50 is the particle size corresponding to the cumulative mass fraction of solid particles in drilling fluid,μm;∆pmax,∆pmin is the maximum and minimum values of the leakage pressure difference,MPa;φmax,φmin is the maximum and minimum values of porosity;Kmax,Kmin is the maximum and minimum values of permeability,mD;αΔp,αφ,αK are the weights of leakage pressure difference, porosity, and permeability, respectively.

The weight is determined by the actual geological factors. After summarizing the relevant data of the lost wells in Block X and conducting statistical regression analysis, it was found that when the weight αΔp,αφ,αK of the block is 0.6, 0.2, and 0.2 respectively, the determination of the lost well layer is more accurate. If the comprehensive index of well leakage is greater than 0.8, it can be determined as well leakage.

2.2 Analysis of Leakage Channel Types and Dimensions

When the average pore throat diameter of permeable formations is greater than three times that of drilling fluid D50, leakage is prone to occur under the pressure difference; When the crack opening of a fractured formation is greater than the drilling fluid D50, well leakage is prone to occur under pressure differential conditions. Therefore, the average pore throat radius and crack opening of the formation are used as two typical parameters for evaluating leakage channels in lost formations.

2.2.1 Prediction of Pore Throat Radius in Permeable Formations

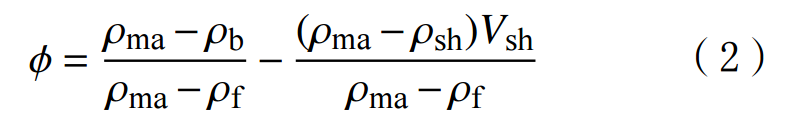

1) Porosity calculation. The single mineral cementitious rock model is suitable for porosity calculation in Block X, mainly using density logging values for calculation:

In the formula:ρb is the density measured by density logging,kg/L;ρf and ρma are the densities of pore fluids and rock skeletons, respectively,kg/L;Vsh is the mud content;ρsh is the density of mudstone,kg/L;φ is the porosity of rocks.

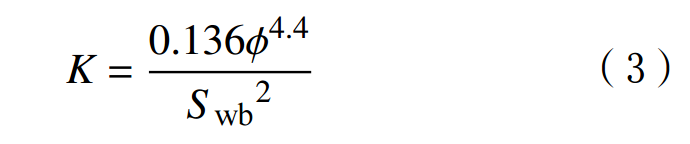

2) Permeability calculation. Based on the analysis of actual data in Block X, the Timur formula is selected to calculate the permeability:

In the formula:Swb is the saturation of bound water;K is the absolute permeability,mD.

3) Prediction of pore throat radius. First, use equations (2) and (3) to calculate the porosity and permeability of the formation, and then calculate the average pore throat radius of the formation:

2.2.2 Prediction of Crack Opening in Fractured Formations

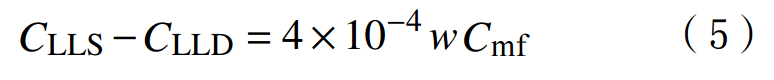

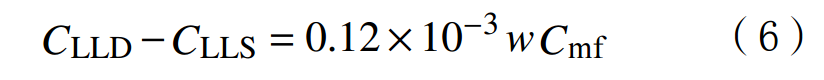

The response characteristics of dual lateral logging in the leaky layer can reflect the characteristics of fractures, and it can be used to calculate the opening of fractures at different dip angles. The calculation formula for the opening of high angle cracks is:

The calculation formula for the opening of low angle cracks is:

In the formula:w is the opening degree of cracks,μm;CLLS,CLLD are respectively deep and shallow lateral conductivity,S/m;Cmf is the conductivity of drilling fluid filtrate,S/m.

Among them, the inclination angle of cracks is determined by the lateral resistivity of deep and shallow layers.

2.3 Analysis of Leakage Pressure Differential Calculation Model

Leakage pressure difference is a key parameter for studying the leakage properties of drilling fluids. From the perspective of pressure difference and basic conditions of well leakage, the pressure difference of leakage is the positive pressure difference of the fluid on both sides of the wellbore wall during well leakage. A leakage pressure difference analysis model was established based on the degree of formation cementing compaction and the characteristics of leakage channels under different well leakage conditions.

In formations with high porosity, permeability, or the presence of natural fractures or karst caves, if the pressure inside the wellbore is greater than the pore pressure of the formation, it is possible to experience well leakage. The pressure difference of the leakage is approximately:

In the formula:∆p is the leakage pressure difference,MPa;pb is the wellbore pressure,MPa;pp is the pore pressure of the formation,MPa.

In formations with low porosity and low permeability and good compaction, if the pressure inside the wellbore is greater than the formation fracture pressure, it can cause induced fracturing leakage. The formula for calculating the leakage pressure difference that induces crack induced leakage is:

In the formula:pf is the fracturing pressure of the formation,MPa.