Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

At present, although oil-like HBPE has been directly prepared using α-palladium diimide as a catalyst for ethylene oligomerization and has the potential for synthetic lubricant applications, there are still some problems.

Firstly, the low-temperature flowability of the product polyethylene oil needs to be further improved. The pour point is the lowest temperature at which the oil can flow, while the glass transition temperature is the temperature at which the polymer chain segment begins to move. Although the glass transition temperature is relatively low, the pour point often does not meet the requirements; Secondly, the branched structure of the product is mainly composed of methyl short branched chains, with a low content of long branched chains, and a lower viscosity index compared to poly α-olefin lubricants with the same molecular weight; In addition, palladium catalysts have higher prices and lower catalytic activity, which will greatly increase production costs; Finally, the thermal stability of α-palladium diimide is poor, and it is prone to the formation of palladium black, resulting in complex post-treatment processes for the product.

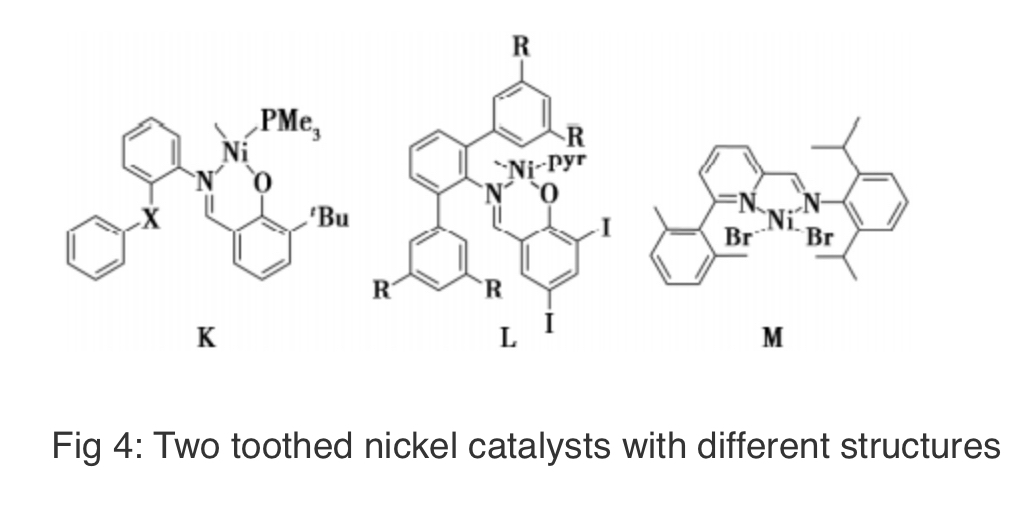

In order to avoid using low activity, poor thermal stability, and high price α-diimide palladium catalysts to prepare oil-like HBPE, nickel catalyzed synthesis of HBPE oil was also studied. A series of nickel complexes K-M with different structures have been designed and synthesized (see Figure 4), which can not only catalyze ethylene oligomerization to prepare oil-like HBPE, but also achieve functionalization of HBPE oil. However, there has been no research on the related application performance.

In addition to journal articles, patents for the direct preparation of polyolefin lubricants through ethylene chain walking polymerization have been gradually disclosed. Tang Yong's research group has applied for multiple invention patents in the direct preparation of polyolefin lubricating oil through olefin polymerization. For example, in 2011, they applied for a patent for a catalytic system for preparing highly branched alkanes from olefins, protecting various α-diimide nickel palladium catalyst systems. The Chen Changle research group has applied for a patent on "a catalyst ligand and its complex for direct synthesis of lubricant base oil from ethylene, as well as its preparation method and application", protecting a class of asymmetric and side arm effects α-Diimine nickel catalyst. Fu Zhisheng's research group has applied for a patent for "a liquid polyethylene rubber and its preparation method", protecting the liquid hyperbranched polyethylene rubber. The catalyst is a new type of acenaphthene quinone skeleton α-diimide nickel designed and synthesized by his research group. Recently, our research group applied for a patent for a saturated polyolefin lubricant base oil and its preparation method. By adding a chain transfer agent to reduce the molecular weight of the product, while avoiding the occurrence of β-H elimination reaction and inhibiting the formation of double bonds, we directly obtained a saturated low molecular weight polyolefin lubricant base oil.

The above research results indicate that chain walking polymerization can directly catalyze ethylene oligomerization to prepare polyolefin lubricating oil, thereby achieving the high value of polyethylene. People have been able to achieve structural regulation of low molecular weight HBPE oil through the structural design of catalysts. However, there are few reports on the relationship between the application performance, especially the viscosity temperature performance and low-temperature flowability, and microstructure.

3.HBPE Dispersant

HBPE can not only be used as a new type of elastomer and lubricant, but also as an efficient dispersant for the preparation of carbon nanomaterials such as graphene and carbon nanotubes (CNT). Compared with traditional chemical vapor deposition and epitaxial growth methods, HBPE assisted liquid phase stripping has the advantages of low energy consumption and simple process. Moreover, HBPE assisted liquid phase stripping can also achieve the macro preparation of high-quality graphene.

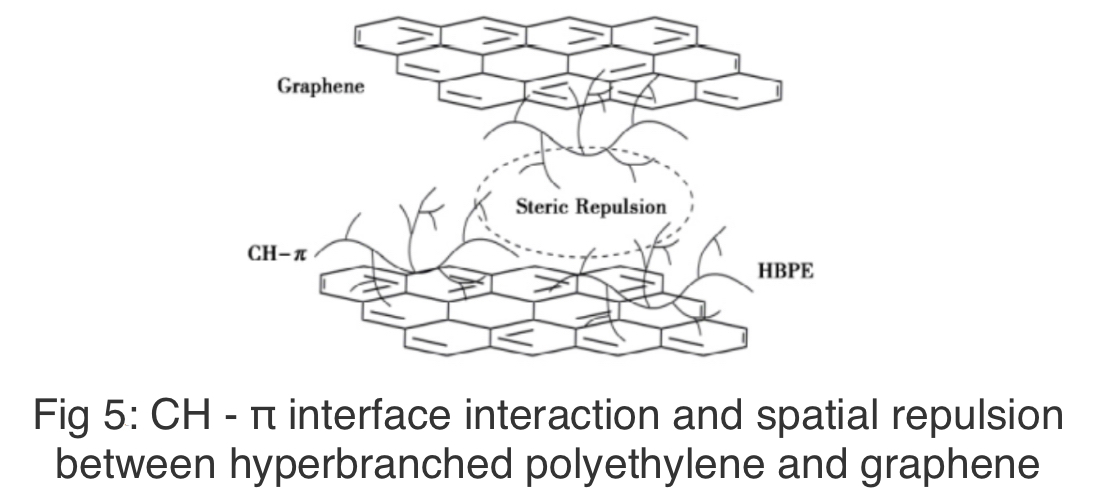

In addition, compared to traditional pure solvent and surfactant assisted liquid phase stripping, HBPE assisted liquid phase stripping has the following advantages: ① No need to use high boiling point solvents, which is beneficial for post-processing; ② The strong interfacial interaction between HBPE and graphene or CNT is conducive to the detachment of graphite, resulting in a high concentration dispersion; ③The spatial repulsion between HBPE adsorbed on the surface of graphene or CNT can improve the long-term stability of the dispersion; ④The obtained dispersion can be directly used for the preparation of polymer nanocomposites by solution method.

Therefore, the method of preparing high-quality graphene by HB-PE assisted liquid phase stripping has rapidly developed. Hyperbranched polymers not only provide strong interfacial interactions but also form significant spatial repulsion, making them widely used in the stripping and dispersion of graphene and CNT. Among them, HBPE has been widely used in this field due to its simple synthesis process (see Figure 5).

When studying the composite materials of linear polyolefin and CNT, the Baskaran research group found that there is an intermolecular CH-π interface interaction between polybutadiene and CNT, and all composite materials with a mass fraction of 1% CNT can dissolve into a homogeneous system, indicating that effective dispersion of CNT can be achieved through this interaction. On this basis, the Ye research group used the HBPE synthesized by α-palladium diimide catalysis for the dispersion of CNTs. The research results indicate that although there are no functional groups on the HBPE molecular chain, efficient dispersion of CNT can still be achieved through non covalent and non-specific interface interactions. The concentration of CNT dispersion is as high as 1235mg/L, which is even better than that obtained through specific π-π interactions.

In recent years, Xu Lixin's research group has conducted extensive research on the preparation of graphene by liquid-phase exfoliation of graphite using HBPE and functionalized HBPE. Firstly, they conducted graphite exfoliation studies using unfunctionalized HBPE. The results of transmission electron microscopy (TEM), atomic force microscopy (AFM), and Raman spectroscopy (Roman) tests showed that the resulting graphene nanosheets had a thickness of 2-4 layers and a two-dimensional size of 0.2-0.5μm. And there are almost no structural defects. And it has been confirmed through infrared spectroscopy that there is also a CH-π interface interaction between graphene and HBPE. Therefore, low boiling chloroform or tetrahydrofuran can be used to effectively peel off graphite, and the concentration of the concentrated dispersion can reach up to 3.4mg/mL. Due to the dendritic structure of the HBPE used, there is a significant steric hindrance between the peeled graphene nanosheets, resulting in excellent storage stability of the graphene dispersion.

In addition, the results of thermogravimetric analysis showed that the HBPE adsorbed by graphene obtained in chloroform and tetrahydrofuran were 28% and 46%, respectively. Recently, they have designed and synthesized functionalized HBPE with pyrene and cage type polysilsesquioxane (POSS), respectively. They not only obtained high concentration graphene dispersion, but also prepared corresponding polyolefin and polysiloxane nanocomposites through solution method. Due to the adsorption of polymers on the surface of graphene nanosheets, not only can their dispersion in the polymer be improved, but also interface interactions can be improved, significantly improving the mechanical, electrical, heat, and thermal conductivity of composite materials.

The above research results indicate that HBPE can not only serve as an efficient dispersant for functional nano filler CNT, but also assist in liquid phase detachment to achieve the transition from cheap graphite to high-performance graphene, and significantly improve the stability of the dispersion. The dispersion of the obtained nano fillers can be directly used for the preparation of polymer composite materials by solution method, which not only improves the dispersion degree of graphene but also improves the modification efficiency.

4.Summary and Prospect

After 20 years of development, the basic research of HBPE new materials has been fully developed and has now entered the initial stage of application research. Compared with existing similar products, HBPE type elastomers, lubricants, and dispersants have significant advantages in production process and performance, thus having good application prospects.

For polyolefin elastomers, although there are currently a large number of varieties available for research and application, these elastomers often require expensive long chain α-olefins as comonomers or require multi-step production processes, while HBPE elastomers do not require comonomers and the production process is simple.

For polyolefin lubricating oil, the production process advantage of HBPE is more obvious because the initial raw material for synthesizing poly α-olefin lubricating oil is ethylene, which is directly used to prepare lubricating oil, eliminating the two-step selective synthesis process. This not only greatly simplifies the production process, but also significantly improves the yield.

For the preparation of graphene and CNT dispersions, especially for the efficient stripping and stable dispersion of graphene, the HBPE synthesis process is simple, the stripping efficiency is high, and the stability effect is good. Although HBPE materials have shown good application prospects in these areas and the raw material ethylene is cheap, there are still some problems that need to be solved before industrial application.

The first issue is the performance and price of the catalyst. The catalyst for synthesizing HBPE materials mainly consists of α-diimide nickel palladium complexes. Compared to nickel based catalysts, α-diimide palladium is not only expensive, has low catalytic activity, but also has poor thermal stability. Therefore, α-diimide nickel is more likely to become a catalyst for the industrialization of new HBPE materials.

The second issue is the production process, including the catalyst synthesis process and the production process of HBPE. The synthesis process of classical α-diimide nickel palladium catalysts is relatively simple, but in order to obtain high-performance and controllable HBPE materials, molecular design of the catalyst structure is often required, which makes the synthesis process of the catalyst relatively complex and increases production costs. Chain walking polymerization products differ from traditional polymerization products in terms of structure and performance, especially for oil-like HBPE products, whose production process needs to be redesigned and optimized.

The third issue is the relationship between material structure and performance. After 50 to 60 years of development, mature theories have been formed for traditional low-density polyethylene (LDPE), high-density polyethylene (HDPE), and linear low-density polyethylene (LLDPE) materials, based on chain structure and material properties related to molecular motion, condensed state structure and product properties related to molding and processing. However, the microstructure of HBPE type elastomers and lubricants, especially the relationship between condensed structure and performance, is almost blank.