Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.1.3 High Resolution Imaging Technology

High resolution imaging technology refers to the use of scanning electron microscopy, laser confocal technology, and CT scanning technology to obtain high-resolution core images, thereby intuitively characterizing the changes in the original oil components in micro pores, the distribution characteristics of remaining oil, and the relationship between remaining oil distribution and clay minerals. Combined with displacement equipment, it can provide spatial distribution information of oil and water in core models at different displacement times, and quantitatively analyze remaining oil saturation. Due to the small size of micro residual oil and complex influencing factors, high-resolution imaging technology is the main means for future research on the micro distribution of residual oil. The technical advantage lies in the significant research effect on the micro residual oil formation mechanism, abundance, and spatial distribution pattern in rock cores with relatively single pore structures. The study of micro residual oil characteristics in large-scale heterogeneous reservoirs is a problem that needs to be considered in the future development of this technology.

2.1.4 Magnetic Resonance Imaging Technology

The principle of nuclear magnetic resonance imaging technology is based on the phenomenon of nuclear magnetic resonance to determine the nuclear magnetic signal in rocks and infer the oil and water content in underground reservoirs. Liu Fan and others applied nuclear magnetic resonance imaging technology to study the microscopic distribution of residual oil in core pores before and after polymer flooding. The results show that after the displacement is completed, the remaining oil is mainly distributed in the areas not affected by the middle and low permeability layers, as well as in the small pores of the low permeability layers. Zhang Shunkang et al. conducted water flooding experiments based on nuclear magnetic resonance two-dimensional spectra, and compared and analyzed the oil-water changes in different displacement stages. The results show that with the development of water flooding, the proportion of continuous residual oil decreases, but compared with network and island residual oil, its absolute volume is equivalent in the later stage of water flooding and still has great development potential.

The sensitivity of nuclear magnetic resonance imaging technology to fluid motion and the applicability of large-sized samples give it unparalleled advantages in studying the microscopic distribution of residual oil during displacement processes. However, the disadvantage is that due to the limitation of signal-to-noise ratio, the spatial resolution of nuclear magnetic resonance imaging technology is currently lower than that of CT scanning technology. The future development direction of this technology in the study of micro distribution characteristics of remaining oil is to improve resolution and imaging analysis under complex reservoir conditions.

2.2 Research Methods for Macroscopic Distribution of Remaining Oil

2.2.1 Numerical Simulation Methods

Numerical simulation method is currently the most widely used method for studying and predicting residual oil saturation at the reservoir scale. Commonly used numerical simulation software includes CMG, ECLIPSE, Tnavigator, VIP, SURE, GrandTM, etc. Quan Bo et al. used the method of equivalent characterization of small-scale geological bodies, which achieved precise characterization of the influence of thin interlayers on permeability and remaining oil distribution in reservoir numerical simulation by setting the grid conductivity between units. The results show that this method can effectively improve the accuracy of single well historical fitting and the prediction accuracy of inter well remaining oil distribution. In response to the problem of significant changes in reservoir permeability and oil-water phase permeability curve after entering the medium to high water cut period in water drive development of oil fields, Wei Feng developed a time-varying simulation framework that can fully consider real-time changes in various seepage parameters. This new simulation technology was applied to a high permeability loose sandstone oil reservoir in a certain offshore area. Based on the existing seepage time-varying laws in this block, the remaining oil distribution, final recovery rate prediction, and potential tapping measures were studied under the consideration of time-varying conditions.

In the later stage of reservoir water injection development, the dispersion degree of remaining oil becomes higher and higher, gradually transforming from continuous phase to non continuous phase such as porous, droplet, and membrane. The difficulty of its utilization and migration also gradually increases. At this time, it is not appropriate to use Darcy's law to describe its migration law, and the characteristics of non continuous phase seepage should be considered. Based on a large number of indoor physical simulation experiments, a nonlinear seepage characteristic mathematical model considering discontinuous phases was established during the high water content period. This model mainly includes two aspects: firstly, the nonlinear characteristics caused by flow velocity can be represented by the ratio of fitted nonlinear pressure difference to theoretical linear pressure difference (Mnl); The second reason is the start-up pressure gradient of the oil phase caused by the discontinuity of the oil phase, which represents the minimum pressure gradient threshold required for the migration of remaining oil during the ultra-high water cut period.

Mnl is judged based on actual flow velocity:

.png)

The relationship between the starting pressure gradient of discontinuous oil phase and the remaining oil saturation can be fitted as:

.png)

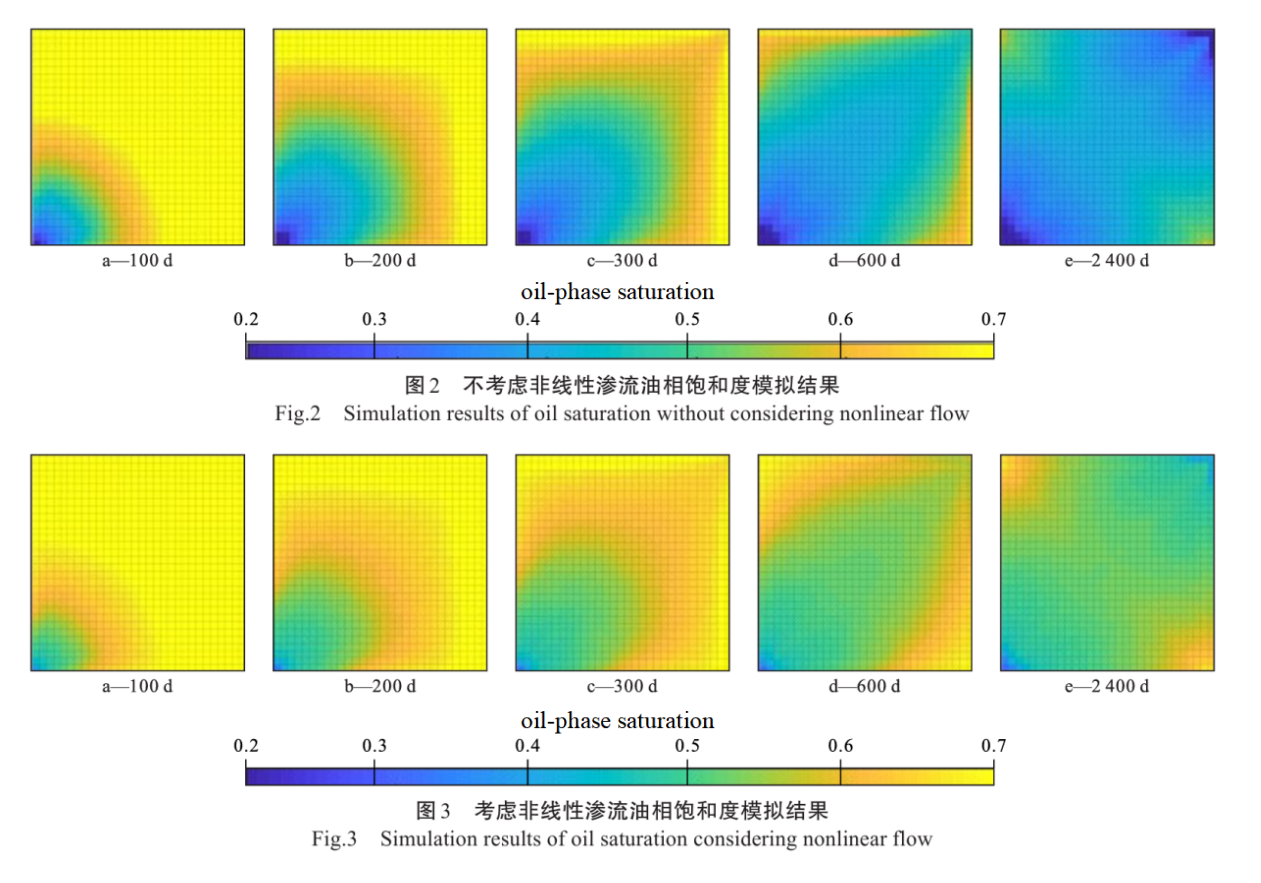

Based on matlab for numerical simulation calculation, a typical numerical simulation model of one injection and one production is established. The permeability is 200mD, the viscosity of crude oil is 2mPa·s, and a fixed liquid volume of 20 m3/d is used to produce 2400d. By comparing the simulation results of oil saturation (Figure 2, Figure 3), it can be observed that after considering nonlinear seepage, as the remaining oil saturation decreases, the starting pressure of the oil phase increases, and the remaining oil becomes increasingly difficult to drive out. The remaining oil saturation in the affected area is greater than the simulation results without considering nonlinear seepage. From the perspective of the coverage range, considering the non-linear seepage model, the coverage is worse, and the displacement effect of residual oil on both sides of the main flow line is lower. There is still residual oil enrichment on both sides of the main flow line in the model, and the oil saturation can reach 0.7 or above. Meanwhile, comparing the production dynamic curves (Figures 4 and 5), it was found that the water content in the simulation results of the nonlinear seepage model increased faster, reaching over 90% about 100 days earlier than the conventional model, and the recovery rate was nearly 4 percentage points lower than the conventional model. The simulation results are more in line with the actual situation of the reservoir, effectively improving the numerical simulation accuracy of high water cut reservoirs.

.png)

.png)

The advantage of numerical simulation methods lies in their comprehensive and intuitive simulation of oil and gas flow patterns, which can quantitatively analyze and predict changes in remaining oil saturation at different displacement stages and spatial distributions.The disadvantage is that the accuracy of numerical simulation results greatly depends on basic data, software platforms, and the experience and level of researchers. The development trend of numerical simulation methods lies in improving them to predict remaining oil more quickly and accurately; Develop new numerical simulation technologies, such as molecular simulation, artificial intelligence, etc.

2.2.2 Four Dimensional Seismic Technology

Four dimensional seismic technology utilizes changes in reflected and seismic waves to monitor changes in rock and fluid properties inside oil reservoirs. This technology is mainly used for monitoring reservoir pressure, fluid movement, and changes in rock properties, and can identify dead oil zones, deploy infill wells, correct reservoir geological models, etc. It provides important data and guidance for optimizing oil recovery plans and improving oil recovery efficiency.

The advantage of four-dimensional seismic technology in residual oil research is that it can provide high-resolution images of underground reservoirs over time through long-term monitoring, quantifying the distribution and flow status of residual oil in the reservoir. The disadvantage is that four-dimensional seismic technology requires long-term monitoring and a large amount of data processing work, resulting in high costs. High geological conditions are required for underground reservoirs, making it difficult to implement in heterogeneous terrestrial sedimentary reservoirs. The future development trend of this technology mainly includes the improvement of data processing and interpretation technology, interdisciplinary application with geology, geophysics, computer science and other fields, and the development of new monitoring technologies.

2.3 Quantitative Analysis and Research Methods for Residual Oil Saturation

2.3.1 Logging Techniques

Logging technology is an effective means of directly detecting remaining oil. According to well conditions, logging technology can be divided into open hole logging and cased well logging. As shown in Table 2, the main technical characteristics and applicable conditions of different logging techniques have been summarized. On the basis of fully understanding the technical characteristics and applicable conditions of existing logging methods, we should follow the principles of geological constraint logging, core and dynamic production scale logging, and logging serving geology and development, and carry out the selection of remaining oil logging methods and technical work deployment.

.png)

The advantages of logging technology lie in the collection of a large amount of information, wide coverage, high sampling density, and the ability to reflect various parameters under geological conditions in real time. The disadvantage is that for complex lithology and long-term water injection formation conditions, a single logging method is difficult to apply to various types of reservoirs. The development trend of logging technology is mainly reflected in the research and development of new logging techniques, the collaborative work of open hole logging and cased well logging, and the introduction of modern mathematical methods into the interpretation and modeling of remaining oil logging.

2.3.2 Tracer Technology

In the early 1980s, China began to develop and apply tracer technology in Dagang Oilfield and Shengli Oilfield. Up to now, four generations of technologies have been developed, including chemical tracer, radioactive isotope tracer, stable isotope tracer, and trace substance tracer. The principle of tracer technology is to inject tracer from the injection well and follow the fluid movement into the reservoir. After sampling and analysis in the monitoring well, combined with geological models and numerical simulation methods, tracer interpretation is carried out to obtain important information such as block flow lines, stratification, heterogeneity characteristics, remaining oil saturation, etc., providing data basis for oilfield development adjustment.

The advantage of tracer technology lies in its lower cost and simpler operation compared to mechanical detection equipment such as distributed optical fibers and continuous tubing cables. The disadvantage is that it may have a certain degree of impact on groundwater and the environment. The development trend of future tracer technology lies in expanding its application scope in oilfield development by improving its accuracy, efficiency, environmental friendliness, and intelligence.