Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

2.3 ZQ-1 Low-temperature Early Strength Mechanism

At 20℃ and 5℃, ZQ-1 has a significant strengthening effect on cement strength, effectively promoting the low-temperature hydration process, and the macroscopic strengthening performance is reflected by the microscopic characteristics. Therefore, SEM and XRD were used to analyze the cement paste mixed with ZQ-1 to explore the low-temperature strengthening mechanism of the composite low-temperature early strength agent ZQ-1.

(1) SEM Analysis of Cement Stone

After curing the blank sample and cement mixed with ZQ-1 at 20℃ and 5℃ for 12 hours, remove and prepare the sample, and observe its microstructure using a scanning electron microscope (see Figure 5). From Figure 5, it can be seen that as the curing temperature decreases, the hydration activity decreases. At 20℃, the amount of hydration products of cement paste without composite early strength agent ZQ-1 is not much, and there is a small amount of flocculent C-S-H gel on the surface of cement particles, but the degree of hydration is low, the particle contour is vaguely visible, there are many pores between particles, the whole structure of cement paste is relatively loose, and still does not have mechanical strength. When the temperature drops to 5℃, the unhydrated cement particles fill the entire system, with numerous microsphere like C3S and cement clinker particles that have not yet participated in the reaction. The entire cement slurry has no hydration activity, and the hydration rate is slow, with extremely low hydration degree.

With the addition of ZQ-1, at 20℃, the network structure of the hydration products in Figure (A) becomes denser, and a large number of hydration products C-S-H are glued together and distributed more evenly. The hydration products form a regular network structure with each other, and the cement stone structure is further compacted; When the curing temperature is 5℃, it is evident from Figure (B) that a large number of clustered hydration products are present. These clustered hydration products are interconnected, and the degree of hydration is significantly improved compared to blank cement paste.

From this, it can be seen that ZQ-1 greatly stimulates the hydration activity of cement slurry in the early stage of cement hydration at low temperatures, accelerating the hydration process of cement slurry. Early strength agent ZQ-1 improves the hydration degree of cement slurry in the early stage of hydration, and microscopic analysis also provides good evidence of macroscopic mechanical test results.

(2) XRD Analysis of Cement Stone

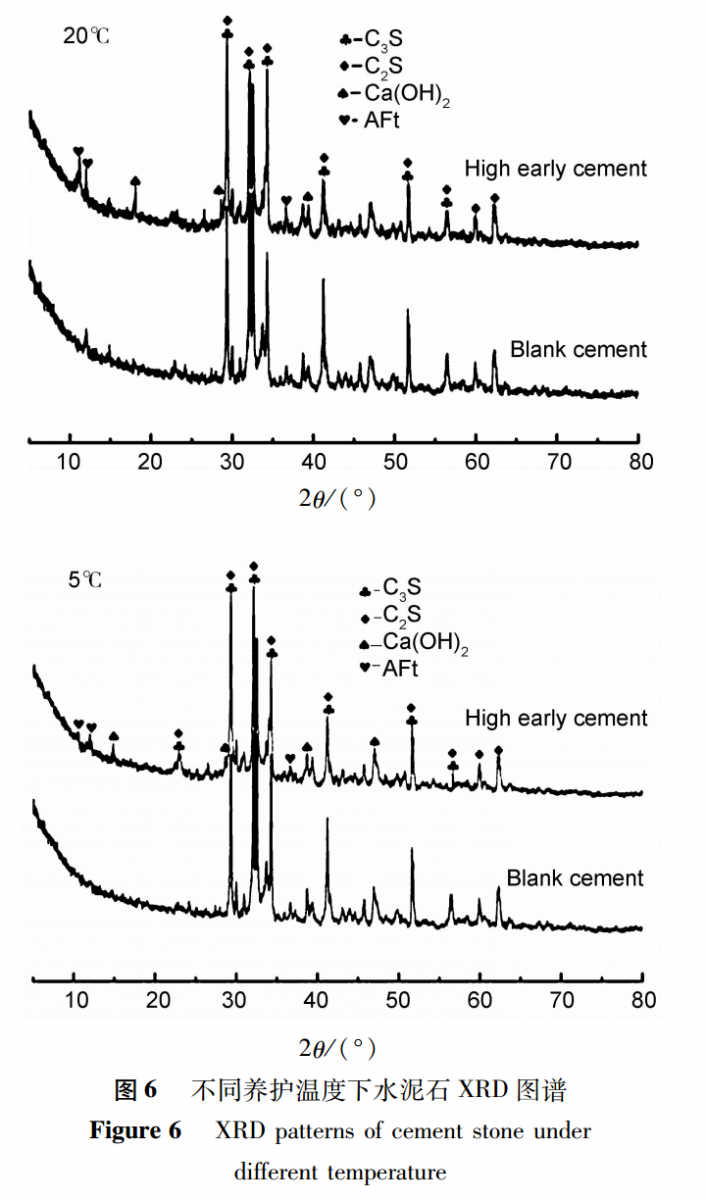

Take out the blank sample and cement mixed with ZQ-1 after curing at 20℃ and 5℃ for 12 hours, and prepare the sample for XRD analysis. The analysis results are shown in Figure 6. From Figure 6, it can be seen that both the blank cement paste and the cement paste mixed with ZQ-1 contain diffraction peaks of C3S, C2S, AFt and Ca(OH)2 in their mineral composition diffraction patterns after curing in different low-temperature environments, indicating a low hydration rate of cement slurry at low temperatures.

From Figure 6 (upper figure), it can be seen that when the curing temperature is 20℃, the diffraction peak of Ca(OH)2 can be clearly seen in both the blank sample and the cement paste mixed with ZQ-1. The diffraction peak of hydration products in the cement paste mixed with ZQ-1 is higher than that in the blank sample. The diffraction peak intensities of C3S and C2S are lower compared to those at 5℃, indicating that higher temperatures promote cement hydration, while ZQ-1 has a significant effect on accelerating cement slurry hydration. When the curing temperature is 5℃, the diffraction peak of Ca(OH)2 in the blank cement slurry is very weak, but the diffraction peaks of C3S and C2S are very strong, indicating that the hydration reaction rate of the blank cement slurry is very low and the process is slow. The diffraction peak of Ca(OH)2 in the cement mixed with ZQ-1 is significantly stronger than that of the blank sample, and there is a weak AFt diffraction peak of the hydration product. The diffraction peaks of C3S and C2S are also lower compared to the blank group, indicating that the addition of ZQ-1 stimulates the activity of cement hydration at low temperature and accelerates the hydration reaction.

(3) Analysis of Early Strength Mechanism

Low temperature early strength agent ZQ-1 is composed of C-S-H early strength crystal seeds, Na2SO4, NaAlO2, and Li2CO3 in proportion. The addition of C-S-H early strength seed will produce a crystal nucleus liquid interface, which will reduce the free energy of the previous matrix liquid interface. The work required for the replacement of this interface is much less than the new interface. The early strength seed reduces the energy barrier of Ca(OH)2 crystallization on the surface of C-S-H gel. When the two come into contact, the crystal will immediately grow, accelerating the hydration rate of cement, thereby improving the early mechanical properties of cement paste. The early strength crystal seeds of the synthesized C-S-H gel belong to nano particles, and the surface contains a large number of structural bulges and structural depressions, which enable C-S-H to have the ability to absorb ions and molecules. Nucleation and adsorption jointly affect the hydration process of cement slurry, effectively alleviating the crystallization barrier caused by the high concentration shielding effect on the surface of the initial water mud clinker mineral, so that the entire hydration product can grow evenly in the whole system, obtaining a more dense and solid cement stone structure.

At the same time, Na2SO4 can react with Ca2+ generated in the slurry to generate CaSO4, while C3S reacts with CaSO4 to generate high sulfur hydrated calcium sulfoaluminate (AFt). The reaction between NaAlO2 and CaSO4 consumes a large amount of CaSO4, resulting in the rapid reaction of C3A in cement with Ca(OH)2, generating more AFt and improving the early strength of cement paste. Li2CO3 will ionize in cement slurry, and the ionized Li+ has a small radius and strong polarization effect, which can strengthen the effect of C-S-H early strength crystal seed on accelerating the rupture of hydration protective film, shorten the hydration induction period, and improve early strength. Lithium salt will not change the type of hydration products of oil well cement. Its hydration products are mainly C-S-H gel, Ca(OH)2 crystal and a small amount of ettringite AFt crystal, which helps the hydration product crystal to uniformly form a dense microstructure.

3. Conclusion

The C-S-H early strength seed crystal synthesized in this paper has a gelatinous structure with rough surface, and the calcium silicon ratio is 0.94. The C-S-H early strength crystal seed was compounded with Na2SO4, NaAlO2 and Li2CO3 to prepare a composite low-temperature early strength agent ZQ-1.

The composite low-temperature early strength agent ZQ-1 has a significant early strength effect, with a dosage of 5% and a curing temperature of 5℃. The low-temperature early strength agent increases the compressive strength of cement paste from 0 MPa to 0.6, 0.8 and 1.4 MPa at 8, 12, and 24 hours. Microscopic mechanism analysis shows that the nucleation of C-S-H early strength crystal seeds in low-temperature early strength agents, in combined action with Na2SO4, NaAlO2, and Li2CO3, accelerates the rupture of the impermeable membrane on the surface of hydration particles during the hydration induction period, leading to the early end of the cement slurry hydration induction period and entering the acceleration stage, promoting the large generation of AFt and C-S-H, thereby improving the early compressive strength of cement paste at low temperatures.