Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

Abstract: Conventional deepwater drilling in deep water puts forward higher requirements on the performances of drilling fluid because of its special low-temperature and high-pressure environment. In deep water, the inhibition performance of drilling fluids to gas hydrates and good rheological properties under low temperature are key performances of deepwater drilling fluid, while additive- gas hydrate inhibitors and flow-type regulator giving these properties are the key additives.

At present, we usually use the method of temperature / pressure to evaluate the hydrate inhibitor. Change the temperature and pressure in the experiment to determine the formation and decomposition of the gas hydrate, thereby we can judge the performance quality of inhibitor. Usually, we measure the rheological properties of the drilling fluid in the entire temperature segment with the operating range to finish the evaluation of flow-type regulator. It requires that drilling fluid should have the constant rheological characteristics, namely plastic viscosity of the drilling fluid, dynamic shear force, and the readings of six-speed rotary viscometer at low speeds (Φ6, Φ3) are almost unchanged in the entire temperature segment with the operating.

In recent years, with the progress of the development of the offshore oil industry and the advancement of technology, exploration and development of offshore oil is gradually shifting to deep water. However, low-temperature high-pressure in deepwater caused a lot of challenges to drilling operations. Such as the rheological property of drilling fluid at low temperatures, the formation of gas hydrates, the narrow formation fracture pressure window, wellbore stability of seabed shallow, large borehole cleanout, shallow streams and marine environmental protection and other issues.

Therefore, in the design of deepwater drilling, integrated performance of the drilling fluid must be fully considered, in order to meet the special requirements of deepwater drilling. It is the key to the performance of drilling fluid that the ability to inhibit the formation of gas hydrate in deepwater and the good rheological properties of drilling fluid under low temperature and high pressure . And the key performance is given by different drilling fluid admixtures, so the admixture is the key to the deep water drilling fluid additive. The author puts forward the key good methods to evaluate deepwater drilling fluid additives on the basis of investigating domestic and foreign literature and the practical research of the Yangtze university deepwater project,

1. The method to select and evaluate gas hydrate inhibitors

In the case of deepwater drilling, no matter it is water-tomb drilling fluid , oil-base drilling fluid or synthetic based drilling fluid, the inhibition to hydrate of drilling fluid must be fully considered. Hydrate inhibitor is usually added to the drilling fluid to improve the ability to inhibit hydrate. Hydrate inhibitors can be divided into thermodynamic inhibitors, kinetic inhibitors and anti-poly agent according to their inhibition mechanism. And every type of hydrate inhibitor has a lot of varieties to choose from, and with the deepening of the study, some new inhibitors are also constantly being reported out. In practical applications, we should consider many factors specific geological conditions, drilling performance, cost, and other comprehensive consideration to select the appropriate inhibitor. Before put into use in the field, a lot of laboratory evaluation should be done to ensure that the drilling fluid has the capacity to inhibit the gas hydrate.

1.1 The experimental apparatus to evaluate gas hydrate inhibitors

Gas hydrates experimental system mainly consists of high-pressure systems, cooling systems, test systems and other auxiliary equipment. High pressure system includes reactors, high pressure water supply system, gas cylinders, etc. Cooling system consists of antifreeze, freezers and temperature control system. Test system is the key experiment mainly composed various sensors and instrumentation components. Modern laboratory research of natural gas hydrate (NGH) with high testing precision can accurately identify the pressure and temperature conditions of NGH’S formation and decomposition. Various detection methods have been applied to the experiment, such as optics, acoustics, electricity, magnetism and magnetic resonance imaging technology.

In experimental system of natural gas hydrate, the technology to examine the formation and decomposition of hydrate is the key of the experiment, because it is related to the reliability of the experimental results. At present, the experimental device used for evaluation of drilling fluid hydrate inhibitors basically adopts the traditional method of temperature- pressure, namely judge the formation and decomposition of the gas hydrate from changes of temperature and pressure in the experiment process.

1.2 The valuation method of natural gas hydrate inhibitor

In the process of deep water drilling operation, we can adopt the method of some physical to control hydrate’s formation. Such as drilling fluid with low density and good well control measures, etc., but these methods have some limitations. Adding inhibitor is the most suitable control method for deepwater drilling hydrate. Generally speaking, activity that can affect the solution properties of the material can usually be used as natural gas hydrate inhibitors. Such as methanol, ethylene glycol and some salts can inhibit the formation of hydrate to a certain extent. Hydrate inhibitor can be divided into three categories: the thermodynamic inhibitors, kinetic inhibitors and the polymerization retarder according to its mechanism. Thermodynamic inhibitors and kinetic inhibitors are researched and applied more widely, and polymerization retarder will not play a role until in the presence of oil phase, so the general research about it is less. Next, we just explain the main evaluation methods of kinetic inhibitors and thermodynamic inhibitor, respectively.

1.2.1The evaluation method of thermodynamic inhibitors

Adding thermodynamic inhibitors in drilling fluid system is r the most commonly method by far. They mainly increase the competitiveness with the water molecules through their molecules or ions to change thermodynamic equilibrium condition between water and hydrocarbon molecule, so that prevent the formation of hydrate. Or contact with the hydrate directly, move phase equilibrium curve, make the hydrate not stable to lead to the hydrate’s decomposition. So, the thermodynamic inhibitors mainly determine the relative phase equilibrium of hydrate formation through the change of pressure and temperature.

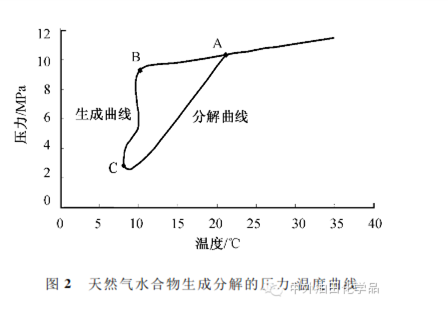

Figure 2 is a pressure- temperature curve of natural gas’s formation and decomposition experiment in the sea water. In Figure 2, from the beginning if the reaction to point B is both one phase for dissolved gas and the hydrate nucleation stage. The inflection point B is the generic point of hydrate. The pressure- temperature curve dramatically changed on this point. The pressure value drastically reduce with the tiny change of temperature (figure 2 illustrates the temperature decrease from point B to point C lead to a sharp decline in pressure). The temperature began to increase from point c. It is decomposition stage of hydrate after point C. The intersection of decomposition curve and formation curve obtained by experiments named point A. which is hydrate phase equilibrium point. The point said hydrate is in a state of balance in theory under the conditions of this temperature and pressure.

Change the initial pressure, and repeat the experiment, we can obtain another phase equilibrium point. After getting a number of phase equilibrium points, we can make the hydrate phase curve (as shown in figure 3) of the system.

Change the initial pressure, and repeat the experiment, we can obtain another phase equilibrium point. After getting a number of phase equilibrium points, we can make the hydrate phase curve (as shown in figure 3) of the system.

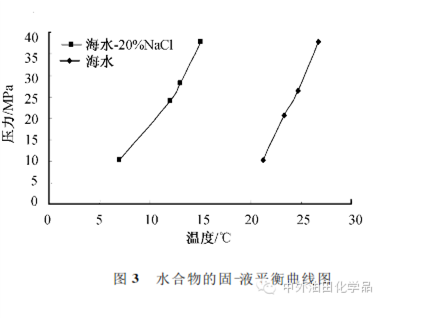

In figure 3, the right one is the phase curve of water - gas system, the left one is the phase curve of water - gas system added 20% NaCI. Compared with the curve on the right, under the same pressure, the hydrate equilibrium temperature is lower on the left curve. It means that NaCl has the ability to inhibit the hydrate. And figure 3 can be used to calculate the decline of the hydrate equilibrium temperature after adding inhibitors relative to hydrate without inhibitors, namely the degree of supercooling. The greater value is, the stronger the inhibition of the inhibitors is.

In figure 3, the right one is the phase curve of water - gas system, the left one is the phase curve of water - gas system added 20% NaCI. Compared with the curve on the right, under the same pressure, the hydrate equilibrium temperature is lower on the left curve. It means that NaCl has the ability to inhibit the hydrate. And figure 3 can be used to calculate the decline of the hydrate equilibrium temperature after adding inhibitors relative to hydrate without inhibitors, namely the degree of supercooling. The greater value is, the stronger the inhibition of the inhibitors is.

1.2.2 The evaluation method of kinetic inhibitors

Kinetic inhibitors mainly can reduce the rate of hydrate formation, prolong the induction time of hydrate nucleation or change the crystal accumulation process. Kinetic inhibitors with hydrophilic groups can form hydrogen bond with solution and water molecules in hydrate crystals, such as poly (N - vinyl pyrrolidone (PVP) and its copolymer, some substances such as sugar and surfactant. These substances cannot prevent the formation of hydrate crystals, but can be adsorbed on the crystal and water interface, and control the growth of hydrate crystals and aggregation.

From the inhibition mechanism of kinetic inhibitors, we can find that it is different to evaluate the inhibition effect between kinetic inhibitors and thermodynamic inhibitors. The performance of thermodynamic inhibitors can be mainly judged from the decline of hydrate equilibrium temperature after adding inhibitors relative to hydrate without inhibitors. The performance of kinetic inhibitors is judged by the length of inhibition time. Experiments show that for drilling fluid system without kinetic inhibitors, under the condition of maintaining a certain degree of supercooling, pressure appear sudden drop at about 5h, which means a lot of gas hydrate were formed. And the pressure of the system added PVP appears sudden drop after about 20 h, which means that kinetic inhibitors PVP can obviously prolong the time of hydrate formation, and it is a kind of available economic inhibitors to control hydrate formation.

2. The evaluation method of flow pattern regulator

During operations under low temperature environment in the deep-water, due to the presence of a low fracture pressure gradient and fragile shale conditions, when drilling fluid circulation pass by the mud line neighborhood, the temperature of the drilling fluid will fluctuate ,and rheological property will change a lot. The specific performances are the sharp rise in viscosity and shear force, also may be rapid gelatination. And result in high equivalent circulating density (ECD), circulation difficulties and pressure leakage layer. So in deepwater drilling, drilling fluid can maintain a constant rheological property with relatively wide temperature scope.

Constant drilling fluid rheological performance can be realized by adding flow pattern regulator. We usually evaluate the pattern regulator of deep water drilling fluid system by testing the rheological properties of drilling fluid system in the whole temperature period of operating range. It requires the PV, YP, Φ 6 and Φ 3 of drilling fluid should change little in the whole period of temperature, in order to meet the requirements of deepwater drilling.

3 Conclusions

1) It requires the drilling fluid should have higher performance, due to the special low temperature and high pressure environment of drilling operation in deep water. Besides conventional properties such as carrier, inhibitory, lubricity, filtration thereof, drilling fluid should also have good hydrate inhibition and the good rheological property under low temperature. The performance of deep water drilling fluid is achieved by adding a variety of additives. In addition to conventional additive, the key additives are natural gas hydrate inhibitors and flow pattern regulator.

2) Adopt a technical evaluation apparatus to evaluate gas hydrate inhibitors. At present common method is pressure nm degree method, namely determining the formation and decomposition of gas hydrate through the pressure and temperature changes in the experimental process, thereby identifying inhibitors performance is good or bad.

3) Usually, we evaluate flow regulator by measuring the rheological properties of drilling fluid in the whole temperature range of the operation. It requires the PV, YP, Φ 6 and Φ 3 of drilling fluid should change little in the whole period of temperature, namely the constant rheological properties.

For more information, please visit Zoranoc's official website:www.zoranoc.com