Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

Abstract

With the increase of water depth in the development of offshore oil and gas resources, environmental loads will significantly increase, posing significant challenges to the operational safety and maintenance costs of offshore pipelines. Compared with traditional steel pipes, marine flexible pipes have advantages such as strong corrosion resistance, good flexibility, and high installation efficiency, making them important equipment for offshore oil and gas transportation. This article reviews the current development status of three types of marine flexible pipe application technologies: submarine flexible pipes, marine flexible risers, and liquefied natural gas low-temperature hoses. It outlines the difficulties and challenges faced in the research and application of marine flexible pipes, and proposes the development trends and suggestions for marine flexible pipe transportation technology.

The China Marine Energy Development Report 2023 points out that in 2023, China's marine crude oil production was 62.2 million tons, with an additional production of about 3.6 million tons, accounting for more than 60% of the country's crude oil production increment for four consecutive years; The marine natural gas production is about 23.8 billion cubic meters, with an additional production of 1.9 billion cubic meters, accounting for about 15% of the national natural gas production increment. China's marine oil and gas production is expected to reach a new level. To further ensure energy security and increase storage and production targets, it is necessary to iterate and update offshore oil and gas extraction technology and equipment to help exploration and development advance into deep water as a whole. As a link between submarine resource production facilities and surface facilities, pipelines are key equipment in the field of deep-sea resource development. Traditional marine pipelines usually use steel pipes, but with the increasing severity of deep-sea environments and water depth, the cost of offshore installation and the risk of fatigue damage will significantly increase. The application of traditional steel pipes gradually shows its limitations, and it is urgent to explore new pipeline materials and structural forms that are more suitable for deep-sea environments.

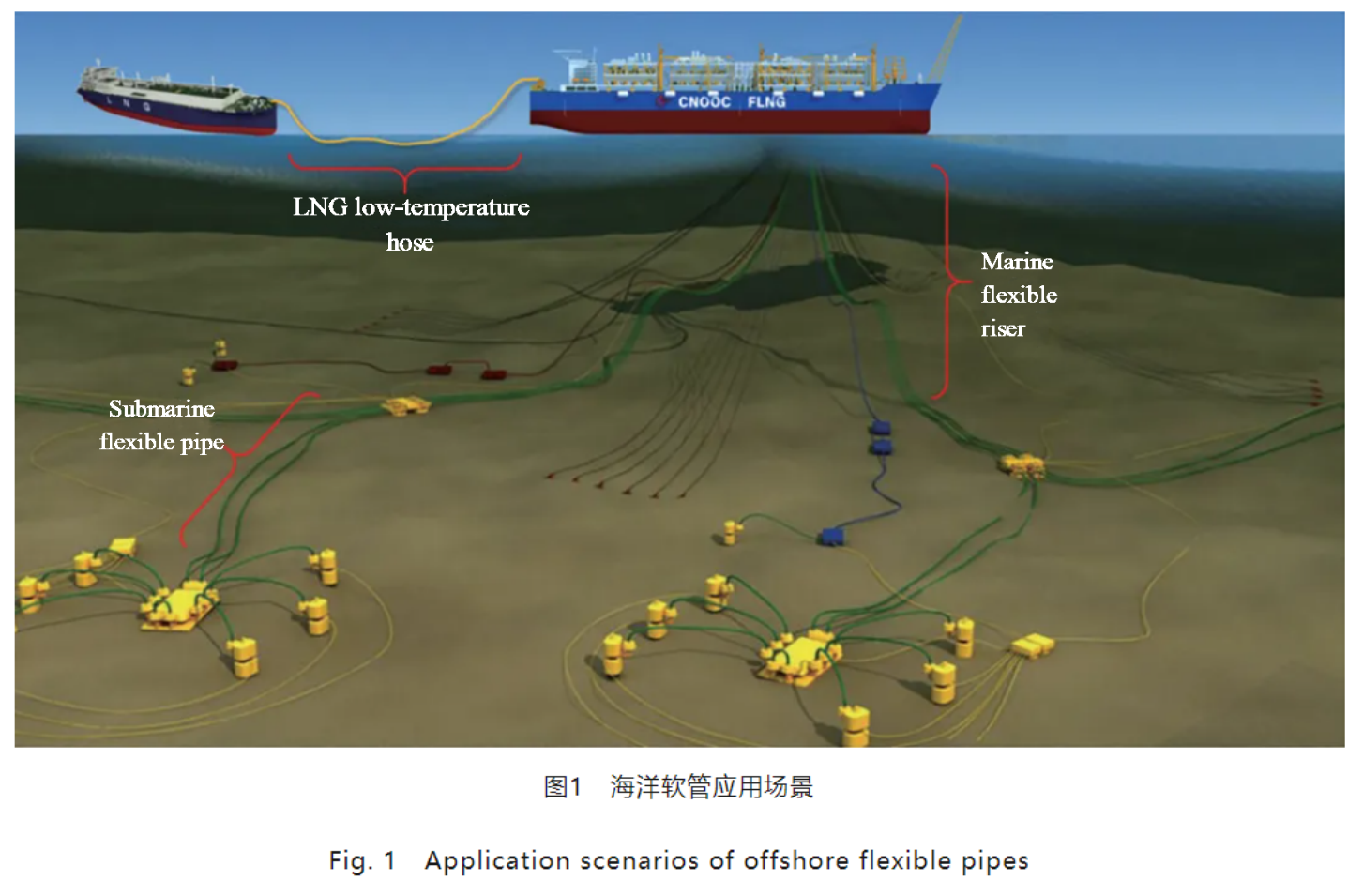

In the exploration and development process of deep-sea oil and gas resources, three types of marine flexible pipes, namely submarine flexible pipes, marine flexible risers, and low-temperature hoses for liquefied natural gas (LNG), play crucial roles. Submarine flexible pipes and flexible marine risers are responsible for transporting oil and gas resources from the wellhead on the seabed to floating facilities on the upper surface of the sea. This transportation process is a key link in the entire underwater production system, and its efficiency and safety directly affect the development cost and production of oil and gas resources. Subsequently, after being processed by offshore production platforms, the produced oil and gas products must be safely transported to land by shuttle ships (such as oil tankers or LNG ships) through sea transportation. LNG low-temperature hoses are the optimal transportation method for connecting platforms and LNG ships in harsh marine environments. Figure 1 is a schematic diagram of the application scenario of marine flexible pipes. Taking the development of natural gas in deep and distant seas as an example, it presents the scenario of natural gas reservoirs being transported from the wellhead through subsea flexible pipes and marine flexible risers to the Floating Liquefied Natural Gas System (FLNG), and then exported through LNG low-temperature hoses.

In summary, all three types of marine flexible pipes are key transportation links for deep offshore oil and gas development, and none of them have fully achieved domestic substitution. In order to further break through foreign technological blockades, solve the bottleneck problem, and independently master key core technologies, this article comprehensively considers the development status of marine flexible pipe technology at home and abroad, summarizes the key technological challenges faced by marine flexible pipes, and puts forward relevant suggestions, aiming to promote interdisciplinary cooperation to accelerate technological progress and promote independent innovation of China's marine flexible pipe technology.

1. Development Status of Application Technology for Marine Flexible Pipes

1.1 Submarine Flexible Pipes

In the underwater transportation system, as the operating water depth increases, the underwater pressure significantly increases, and strict requirements are put forward for the pressure bearing capacity of underwater flexible pipes;The complexity of underwater terrain has an impact on the layout and operational strength of pipelines; In addition, the variability of underwater geological conditions further increases the challenges of pipeline stability and safety; At the same time, in deep sea areas, the lower temperature of seawater may lead to an increase in internal fluid viscosity, a decrease in fluidity, and even in some cases, the precipitation of wax, thereby affecting the transportation efficiency and safe operation of pipelines.

The design of underwater flexible pipes adopts a multi-layer structure, with each layer composed of specific materials, aiming to ensure the reliability and durability of the pipes in harsh underwater environments. From the inside out, the underwater pipe structure mainly includes a skeleton layer, which is responsible for providing radial stiffness and strength to withstand the external pressure of the pipeline; The internal water tight layer is responsible for forming fluid channels and sealing the medium transported inside the pipe; The compressive armor layer and tensile armor layer are made of metal or high-strength synthetic fibers, providing necessary mechanical strength for submarine flexible pipes; Wear resistant layer plays a role in preventing friction and loss between metal layers; The outer covering layer, as the outermost layer, is composed of materials that are resistant to seawater and wear, protecting underwater pipes from external environmental erosion. By adopting this composite structure design, underwater pipes can adapt to the special needs of deep-sea oil and gas transportation, ensuring the safety and reliability of the transportation process. The main structural form of submarine flexible pipes is shown in Figure 2.

.png)

Buckling is a common cause of failure in submarine flexible pipes. In an already installed subsea pipeline system, the temperature gradient of the internal fluid can generate axial loads in the pipeline, which may accumulate in certain parts of the pipeline. Especially when the fluid temperature changes dramatically, the temperature gradient can cause thermal expansion and uneven deformation. At this time, axial forces usually cannot be effectively released through the axial elongation of the pipeline, and may instead lead to overall buckling of the pipeline, thereby affecting the integrity and safe operation of the pipeline. In order to address this issue, a strategy is often adopted in engineering practice: when laying deep-sea submarine pipelines directly on the seabed, selectively inducing controllable thermal buckling of the pipeline at multiple points, thereby dispersing the overall thermal stress of the pipeline. Taking the Echo Yodel project near the northwest continental shelf of Australia as an example, the working water depth in this area is 140-160 meters. During the operation of the pipeline, the project adopted innovative snake laying technology. This laying method effectively disperses and releases the energy of the pipeline through its natural bending, thereby significantly reducing the stress and strain of the pipeline in the post buckling state. This technology avoids the need for artificial manufacturing of suspended pipelines without the need for additional triggering devices, making it cost-effective. At present, there is no unified standard for snake shaped pipe laying internationally, and various engineering projects are still mainly designed and constructed based on experience. In addition, it is also possible to induce controllable buckling by manually introducing a suspended span pipeline to reduce the lateral stability of the pipeline, which is called the vertical disturbance method.

Due to various factors such as design, cost, and construction, underwater flexible pipes often adopt multiphase flow mixed transportation methods. Due to the drastic terrain changes along the pipeline and the high pressure and low temperature conditions in the deep sea area, the temperature of multiphase fluids inside the pipeline will sharply decrease with the increase of transportation distance. This may lead to the formation of hydrates or wax crystals, thereby reducing the flow area of pipelines, and in severe cases, even blocking critical equipment such as pipelines and valves. In order to solve the flow safety problem of multiphase flow mixed transportation pipelines, effective insulation measures must be taken. In addition to the passive insulation method of designing insulation layers, active heat tracing technology can also be used. Active heat tracing provides external heat directly or indirectly to the pipeline to maintain the temperature of the medium inside the pipeline, avoiding hydrate formation or wax crystallization caused by low temperature, and ensuring the safe and efficient operation of the pipeline system.

Since 2007, China has initially developed the production capacity of submarine flexible pipes, and has successively produced flexible pipe manufacturers such as Wudi Haizhong flexible pipe manufacturing Co., Ltd. and Hebei Heng'antai oil pipe Co., Ltd. At present, submarine flexible pipes produced in China can be used at a depth of 150 meters, a design pressure of 27.73MPa, and an internal fluid temperature of 55℃ with good performance. However, compared with products from well-known international manufacturers such as TechnipFMC and Strohm, they still exhibit limitations in application when facing deep-sea environments with greater external pressure and internal fluids with more complex compositions. Currently, Chinese submarine flexible pipe manufacturers have limited product types and lack the refined and diverse design capabilities for pipeline structures under different working conditions, which is prone to oversaturation and singularity in production, and lack distinctive competitiveness in the international market.