Case Studies

Case Studies

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 1)

- Construction of A New Organic-inorganic Composite Emulsion and Its Enhanced Mechanical Properties of Oil Well Cement(Part 2)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 1)

- The Application Prospects of DeepSeek Large Model in Petroleum Engineering(Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 1)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 2)

- Development and Performance Evaluation of Efficient Asphalt Dispersant (Part 3)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 1)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 2)

- Research and Application Status of Drilling Fluid Plugging Materials (Part 3)

Now a new technology has been employed to reduce drilling cost and overcome well leakage. Put a high solid content and high water loss thick slurry( HWL-HS) into the well leakage, a solid plug is precipitated by dehydration. People would rather use this method than take extrusion. Then this high permeability plug is blocked quickly by mud solids. Sometimes it needs to mix plugging materials in the slurry (short for LCM).

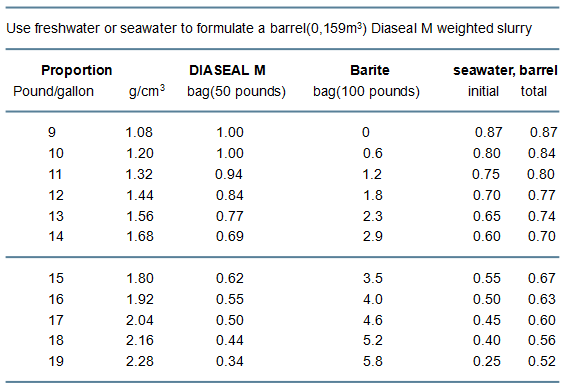

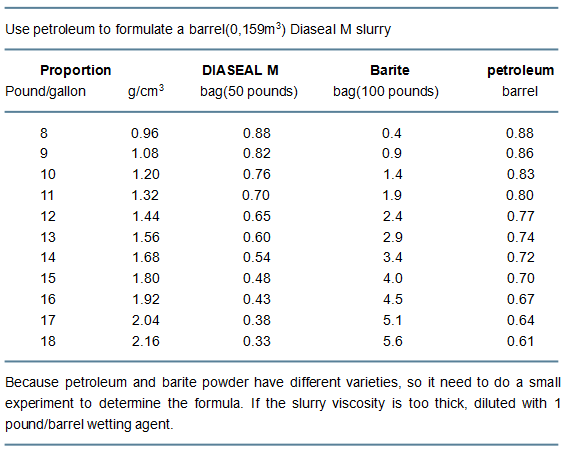

The way to prepare this thick slurry is simple and easy to learn. A common ratio is a barrel slurry plus 50 pounds bag of Diaseal M. Diaseal M is the trademark of a mixture with several materials. It can quickly form a stable and very high water loss slurry. This slurry can aggravate to any specific gravity, and can be stored for immediate use when leakage occurs. The ordinary type has a 200 ml/min of water loss(for the leakage of oil based mud, petroleum is often used to prepare Diaseal M).

When it comes to the issue of well leakage, many staff agree to the following points :

(1). Most well leakage occurs in cracks or holes;

(2). Poor drilling operation often causes cracks;

(3). In order to overcome this type of well leakage, must plug the inside of cracks and not just paste in the wellbore surface;

(4). More mud pumped into the leakage zone, the problem more serious;

(5). LCM can constitute a bridge plug, but there must be fine particles solids to form a permanent closure;

(6). The lower water loss slurry pumped into the cracks, the more cracks expansion;

Slurry without LCM or slurry suitable for fibrous plugging material can pump out from any water hole. In this case, there is no need to pull out the hole bit. If the loss is in the porosity formation, infiltration occurs rapidly and few amount of plugging recycle materials is needed. If it is a low permeability crack loss, slurry will enter the crack without much exudation until the maximum particle size in slurry gets close to the crack width and cannot get down any further. Therefore, large bridge plug material is needed. The severity of loss is determined the number and type of LCM required.

Squeeze pressure is necessary. Because cracks in the beginning of leakage zone tend to be opened and then closed, leakage zone needs to be reinforced to avoid the possibility of future loss. That’s the reason why a weak zone often get into the trouble of continuous well leakage problems when the original well leakage has been overcomed by conventional method and the drilling has get resumed. Squeeze pressure is to ensure the recycling mud and the absence of leakage even with the additional pressure drop in annular space.

The general procedure for weighted slurry :

1. When mixing the slurry, put drill into the sleeve, in order to make enough time to make mud, the mud volume should double the volume of naked hole(at least 100 barrels).

2. Slurry pump to the bottom of the drill pipe or casing outside, close well device after know exactly the borehole is filled, with 1 barrel/min(159 litre/min) displacement pump slurry 20 to the naked eye.

3. When naked eye fill of slurry, off pump and begin exploratory program, within 10 to 20 minutes, With a maximum displacement of 0.5 Nan / minute speed injection of 10 to 20 barrels.

4. Get the support pressure of 300 to 900 pounds per hour, return to work.

The general procedure for unweighted slurry :

1. Safely put on the drill pipe to the drain or into the casing, If the drill pipe in the position of the naked eye, to keep the rotation

2. Preparation of 100 barrels slurry, and into the naked eye.

3. Raised to the casing and fill the borehole through the infusion pipeline, make another slurry if the borehole is not full, and repeat.

4. If the borehole maintain full, close the well device, based on displacement pump injection 0.5 barrels per minute, until get the support pressure of 300 pounds per hour. Waiting two hours if without support pressure, then return to operation.

Example : 100 barrels 14 pound/gallon Diaseal M need 69 bangs Diaseal M, 290 bangs barites, 70 barrels water, it can also add walnut shell when required(25 pound/barrel walnut shell, If added plugging absorbent material, then the slurry viscosity will rise). With 60 barrels water at the beginning of deployment, add the remaining 10 barrels water after adding all the Diaseal M and barite powder.

1). If with saturated brine, every barrel of slurry reduce 0,6 bag barite powder.

2). For heavier system, formulate with a small amount of water to ensure the barite powder added has enough suspended performance.

Diaseal M has many advantages over other lost circulation materials. Because it has a very high water loss, it can plug fully and effectually after getting into the drain layer. Diaseal M slurry neither deteriorates when stored nor pollute the mud. It is equally valid both in water and oil. Either in weighted or unweighted slurry system, it can successfully fight against well leakage.

Diaseal M slurry has a high viscosity at low shear rate. Therefore, it is easy to absorb the air if the slurry is expose to the air when mixing and agitating. In this case, a standard defoaming agent will be helpful.

For more information, please visit Zoranoc's official website: www.zoranoc.com