Estudios de caso

Estudios de caso

- Grandes petroleras van por licitación de aguas profundas

- Schlumberger, How to Strengthen Technology Innovation

- Development and prospect of offshore oil and gas exploration and related applied technology

- Oil shale deep inclined technologies and new development

- Application & Development of Bactericide for Oilfield Flooding in China

- Analysis on New Technology and Application Analysis in Oil and Gas Exploration

- The introduction of new well structure to improve SAGD performance

- Design methods of oilfield development and old oilfield development status

- A New Technology on Formation Fracturing: LPG Anhydrous Fracturing

- A Fracturing Fluid Instant Cellulose Without Dregs

Summary: Early cellulose fracturing fluid had problems such as hard matching liquid, poor temperature resistance, incomplete gelout, big formation damage. Instant cellulose fracturing fluid consists of 0.4% hydroxyethyl carboxymethyl cellulose(HECMA)FAG-500、0.2% viscosifier FAZ-1、0.5% regulators FAJ-305, analyzed salt resistance of the fracturing fluid、thermal stability and shear resistance、prop-carrying、gelout、dynamic filtration and damage. Results show that under moderate salinity(242~2444 mg/L, under the condition, the viscosity of base fluid is 67.5mPa-s, in pH 4.5~5.0, add crosslinking agent in the base fluid, FAC-201 form gel in 120℃, 170s) condition, gel fracturing fluid shear, after 70min with viscosity of 150mPa-s, can satisfy less than 130℃ reservoir fracturing demand. After adding 0.0020/0 gelbreaker ammonium peroxydisulfate, under 100qC、170s condition, shear after 1.5h with viscosity of 200 mPa-s, gelout doesn’t influence the rheological properties of the construction system. After gelout without dregs, the surface tension of gelout liquid is 24.44mN,rm, interfacial tension is 3.20 mN/m. Below 900℃, 0.30/0 FA(i-500) storage modulus of fracturing fluid gel G’ and loss modulus G” are 7.2 Pa and 1.6 Pa. The 40% sand ratio of crosslinking gel sand carrying, after heating 6h in 900 degree water, without sand setting phenomenon, goof sand carrying capability. Permeability damage of fracturing fluid to the core rate is 24.75%. The cellulose fracturing fluid has the characteristics of easy preparation, acid cross-linked, without anti-swelling agent etc. Changqing oilfield two dense wells and two tight wells are applied on site, success ratio greater than 95%, construction efficiency has 100%.

In recent years, fracturing fluid as an important component of fracturing, rapid development. But, after fracturing fluid into the reservoir, interfere the balance condition of the original reservoir. The damage of fracturing fluid system mainly form two aspects :

(1). Because dregs block up pore exist, seriously affect the fracture conductivity. Such as the dregs content of conventional guar gum fracturing liquid between 200~400 mg/L, the mean particle diameter is 74.77p,m, will block up cracks of reservoir natural and fracture.

(2). Gelout liquid can’t flowback, form permanent damage. There is thousands times difference between gas and residue viscosity, gas reservoirs can’t piston displacement flowback residue, permanently residue in reservoir. Reduce the damage made by fracturing fluid to reservoir and fracture capacity support is one of the important technology by improving low permeability oil and gas reservoir. The residue is one of the key factors influencing the fracturing effect, therefore need to study fracturing fluid without dregs.

Besides, depend on import of guar gum in 2012 led to the soaring cost of fracturing fluid and unable to control the situation, looking for an alternative of guar gum to reduce cost has profound implications for the future development of fracturing fluid technology.

Cellulose fracturing fluid are applied in the early of Dagang oilfield and Yumen oilfield, but because cellulose dissolved slowly、difficult crosslinking、poor salt resistance、poor thickening effect、formation damage made by residues etc, no sustainable development. Here the instant cellulose fracturing fluid without dregs, can satisfy the needs of reservoir fracturing less than 130℃. This fracturing fluid system with instant, easy preparation, low friction, low damage, low cost, safety and environmental protection features.

1. Experimental

1.1 Raw material and equipment rate

Hydroxyethyl carboxymethyl cellulose(HECMA)FAG-500、 viscosifier FAZ-1、 regulators FAJ-305、organic zirconium crosslinker FAC-201, were all studied by Langfang branch center of Chinese Petroleum Exploration Institute; Anionic demulsifier cleanup agent DJ-12 or DJ-16 are industrial grade; Hydroxypropyl guar gum, JingKun Chemistry Company Co.,Ltd; Anti swelling agent BFC-3, Beijing BaoChun technology Co.,Ltd.

ZNND6S six-speed rotary viscometer, Qingdao haitongda special instrument Co.,Ltd; Germany Haake TS-6000 rheometer; USA OFI high temperature and high pressure static filtration device; Germany Kruss KI00 interfacial tensionmeter; Narring mixer, spring scientific; Germany Hakke Mars Ⅱas rheometer.

1.2 Preparation and performance evaluation of fracturing fluid system

Preparation mass fraction 0.4Vo hydroxyethyl carboxymethyl cellulose base liquid, then add 0.2% FAZ-1, with mass fraction 400 : 0 acetic acid regulating pH value of 4.5~5.0, add crosslinking agent FAC-201 according to 0.6% of total quality system, stirring for 1.5 min to form a system of good viscoelastic gel.

On the basis of petroleum and natural gas industry standards SY/T 5107-1995《7 torquay jade fracturing fluid performance evaluation method》, determination heat/shear resistance、gel breaking fluid loss、and residue content.

2. Results and discussion

2.1 The basic properties of cellulose fracturing fluid

2.1.1 Salt resistance

The viscosity of base fluid after different times in table 1. From the table, the viscosity of cellulose thickener FAG-500 reaches a maximum value within 2 min 67.5 mPa-s, and can keep stable for a long time, satisfy the construction requirements.

.png)

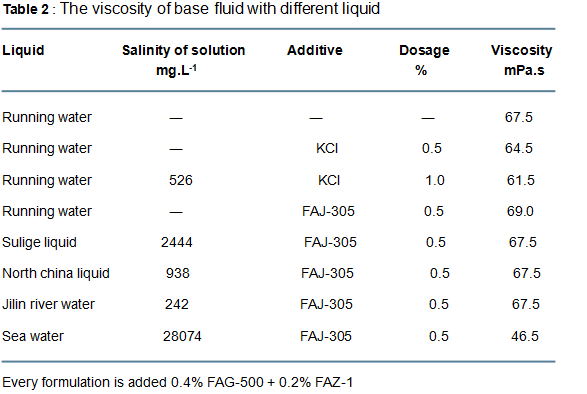

The viscosity of base fluid with different liquid(different salinity) in table 2. From the table, low viscosity of base fluid formulated by seawater; at high KCl content, the viscosity decrease slightly; This system exists sensitive defect to high salinity water(seawater), but can meet water quality condition of general liquid(moderate salinity), there is little difference between base fluid viscosity and running water viscosity, it is thus clear that the system has some salt tolerance.

2.1.2 Temperature、shear resistance

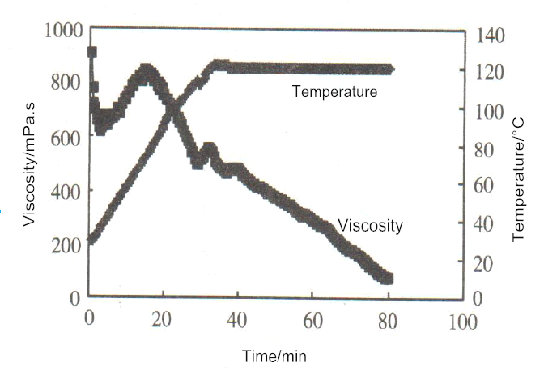

Under 120℃、170 s-1, the viscosity of 0.4% FAG-500 fracturing fluid system measured by rheometer changes with shear time, shown in figure 1. From the graph, the viscosity of gel aster shear 70 min is about 150 mPa-s, better heat resistance, meet mid、high temperature gaps making and sans carrying requirements.

Figure 1 : Temperature、shear resistance of 0.4% FAG-500 fracturing fluid

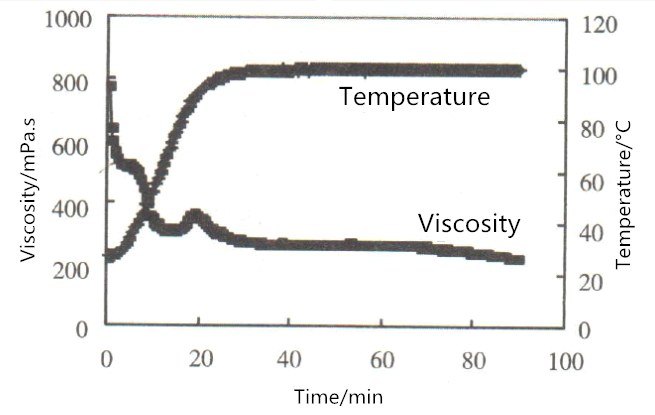

Under 100cC、170s-1, the shearing curve get by adding 0.002% gel breaker to 0.4% FAG-500 fracturing fluid, shown in figure 2. From the graph, the viscosity of gel aster shear 1.5h is about 200 mPa-s, it is visible that gel breaker agent does not influence the rheological properties of the system’s construction.

Figure 2 : Temperature、shear resistance of 0.4% FAG-500 fracturing fluid after adding gel breaker

2.1.3 Viscoelastic and sand carrying capability

Under 90℃, 0.3% FAG-500 gel fracturing fluid’s storage modulus G7 and loss modulus G” were 7.2 Pa and 1.6 Pa with rheometer, more than G7 value of 3.43 Pa hydroxypropyl guar gum fracturing fluid at the same temperature. Preparation of 0.3% FAG-500 crosslinking sand carrying gel fluid with 405 sand ration, after heating 6h in 90℃ wather-bath, the fracturing fluid without he phenomenon of sand setting, good sand carrying properties.

2.1.4 Gel breaking property

Fracturing fluid need to break gel completely after construction, help flowback maximum, reduce the formation and fracture damage. Ammonium persulfate vill not influence the fel formation time、gel’s elasticity, and for the system, by optimizing the dosage, gel completely broken after construction, so as to achieve the purpose of rapid flowback.

2.1.5 Fracturing fluid loss and damage

Under pressure differential of 3.5MPa condition, the static loss properties of cellulose fracturing fluid, shown in table 3. From the graph, compare with conventional guar fracturing fluid system, the cellulose fracturing fluid with large filtration, but adding diesel can reduce the filtration rate, filtration coefficient magnitude from 10-3 down to 10-4. By core flow experiments, measured the filtration damage rate of guar gum 、instant no residue fracturing fluid after gel breaker respectively is 43.7% and 24.75%, it is thus clear that the fracturing fluid has small damage to the substrate.

.png)

2.2 Properties of cellulose fracturing fluid

2.2.1 Instant 、mixing continuously online

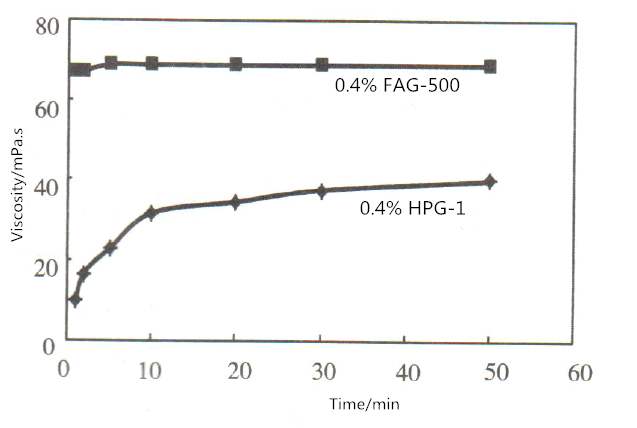

Guar gum fracturing fluid with variety of additives、complex composition、interaction between additives. Such as pH adjusting agent provide a basic environment to guar gum swelling, during formulation exist the order problems, and the mixing continuously online is quick online, there is not enough time to distinguish the added order, bring the difficulty to the preparation. Therefore, simplify the fracturing fluid formulation, reduce interaction between additives, for the realization of large-scale online mixing is very important. Shown in figure 3, modified cellulose FAG-500 can rapidly swelling and thickening within 2 min, achieve the final viscosity of more than 97%; However, conventional guar (HPG-1) fully swelling needs 4h. Modified cellulose thickener has good effect in instant, and the formulation simple, can realize mixing continuously online.

Figure 3 : The viscosity of FAG-500 and HPG-1 at different standing time

2.2.2 Acidic crosslinking without anti-swelling agent

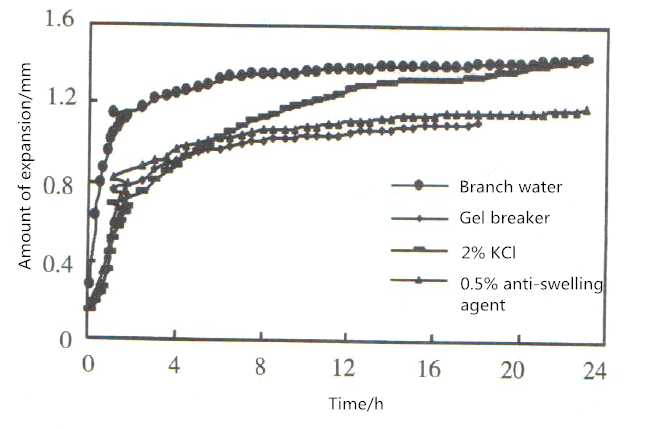

The condition of cellulose fracturing fluid is acidic, can effectively reduce clay swelling. Shown in figure 4, gel breaking liquid expansion is less than 2% KCl and 0.5% BFC-3, indicate that cellulose fracturing fluid without anti-swelling agent also has good anti-swelling effect. In addition, do not add clay stabilizer or anti-swelling agent, help to reduce the cost of fracturing fluid.

Figure 4 : Anti-swelling property of cellulose fracturing fluid gel breaker

2.2.3 Breakable gel without residue

The damage of formation and fractures caused by fracturing fluid, except emulsify、migration of clay swelling、water locking and flowback incompletely, the residue of gel breaking liquid will significantly reduce the fracture conductivity, cause permanent damage, finally lower the increase effect of fracturing. The cellulose fracturing fluid use ammonium persulfate after break gel without residue, measured gel breaking liquid surface tension is 24.44mN/m, interfacial tension is 3.20mN/n. And guar fracturing fluid residue is generally greater than 300 mg/L. Therefore compared with plant guam fracturing fluid, no residue is the most significant advantage of the system.

The prominent characteristic of instant no residue cellulose clean fracturing fluid is lower cost、no residue、low damage、crosslingking. Instant no residue cellulose fracturing fluid is very suitable for low porosity and low permeability, small pore throat radius, sensitive to damage, low damage requirements of foreign fluid for tight oil、gas reservoir, better for reduce construction risk and improve oil and gas production, has a wide application prospect.

3. Conclusion

The formulation of instant no residue cellulose fracturing fluid : 0.4%FAG-500+0.2% FAZ-1+0.5% FAJ-305+0.5%FAC-201. The formulation under 120℃、170s-1 shear 90 min, the viscosity remains more than 150 mPa.s. The system satisfy reservoir fracturing requirements with temperature below 130℃. New cellulose fracturing fluid can control thickening technology, meet the industrialized rapid preparation requirements, and low permeability reservoir of mass volume reconstruction. Cellulose fracturing fluid may partially replace guar, has the profound significance for changing the main fracturing fluid dependent on imports, inhibit the excessive growth cost of fracturing fluid. Fracturing fluid gel breaking completely、no residue、low damage to storage reservoir and fractures, provides strong technical support in order to obtain good effect of fracturing.

For more information please visit Zoranoc's official website:www.zoranoc.com