Case Studies

Case Studies

- Study on the Synthesis and Performance of a Large Temperature Difference Retarder for Oil Well Cement(Part 2)

- Study on the Synthesis and Performance of a Large Temperature Difference Retarder for Oil Well Cement(Part 1)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 1)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 2)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 3)

- New Developments in Oil Drilling Industry Technology

- Research and Application for the Fine Identification Method of Lost Circulation Characteristics During Drilling (Part 2)

- Research and Application for the Fine Identification Method of Lost Circulation Characteristics During Drilling (Part 1)

- Analysis of the Development Status and Trends of Unconventional Oil and Gas Cementing Materials (Part 1)

- Analysis of the Development Status and Trends of Unconventional Oil and Gas Cementing Materials (Part 2)

.png)

Abstract

To solve the problem of slow development of cement slurry strength caused by low temperature environment, this article synthesized C-S-H early strength crystal seeds and prepared an oil well cement early strength agent suitable for deep water and low temperature environment with Li2CO3, Na2SO4, and NaAlO2 as raw materials. Firstly, the chemical composition, structure, and microstructure of C-S-H early strength crystal seeds were analyzed using FT-IR, XRD, EDS, and SEM; Secondly, the early strength performance of composite low-temperature early strength agents was studied. The results show that at 5℃, the low-temperature early strength agent has a significant early strength effect, increasing the compressive strength of cement paste from 0 MPa to 0.6, 0.8, and 1.4 MPa after 8 hours, 12 hours, and 24 hours. The analysis results of early strength mechanism indicate that the nucleation of C-S-H early strength crystal seeds in low-temperature early strength agents, together with Na2SO4, NaAlO2, Li2CO3, accelerates the rupture of the impermeable membrane on the surface of hydration particles during the hydration induction period, leading to the early end of the hydration induction period of cement slurry and entering the accelerated stage, thereby improving the early compressive strength of cement paste at low temperatures.

Deepwater oil and gas resources have become the most important strategic replacement resource for conventional oil and gas resources. Deepwater oil and gas development is more complex due to its unique environment, such as water depth, stratigraphic structure, weather conditions, and lack of oilfield facilities. In the process of oil and gas resource development, deepwater cementing technology is an important guarantee for releasing the production capacity of deepwater oil and gas resources. Deep water cementing faces various challenges such as low temperature, low fracture gradient, shallow flow risk, and natural gas hydrates, which directly affect the safety and quality of cementing. Among these adverse factors, low temperature is the most severe challenge for deep water cementing, with a seabed mud line temperature of about 4℃, which leads to slow development of cement stone strength. The low-temperature environment seriously affects the hydration process of cement slurry, which in turn affects the strength development of cement stone and cannot produce corresponding strength stable casing, affecting the safety of the entire drilling operation.

At present, adding early strength agents is the main method to improve the early strength of deep-water low-temperature cement slurry. However, traditional early strength agents have problems such as low long-term strength, increased shrinkage, and poor durability of cement paste. The early strength components such as Na2SO4, NaAlO2, Li2CO3 have significant early strength effects, and have little impact on the later strength and durability of concrete. Moreover, composite early strength agents can better coordinate the early strength performance of a single component. In deep water and low-temperature environments of 0-5 ℃, there is relatively little research and application of early strength agents, and the effect of low temperature early strength is limited. There is also less research on the mechanism of action of early strength agents at low temperatures and their impact on the performance of cement slurry.

In response to the shortcomings of traditional early strength agents, this paper synthesized C-S-H early strength crystal seeds and analyzed their chemical composition, structure, and microscopic morphology. An oil well cement early strength agent ZQ-1 suitable for deep water and low temperature environments was prepared by using the C-S-H early strength crystal seed and Li2CO3, Na2SO4, NaAlO2 as raw materials, and its reinforcement performance and mechanism were studied.

1. Experimental Part

1.1 Instruments and Reagents

*WQF520 Fourier infrared spectrometer;

*X'Pert MPD PRO type X-ray diffraction energy spectrometer;

*GENESIS XM energy dispersive X-ray spectrometer;

*Quanta 450 environmental scanning electron microscope;

*NYL-300 pressure testing machine.

*G grade oil well cement, Sichuan Jiahua Enterprise Co., Ltd;

*Fluid Loss Agent G80L and Dispersant F41L, Tianjin Zhonghai Oilfield Chemical Co., Ltd;

*All other reagents used are analytical pure.

1.2 Preparation of C-S-H Crystal Seeds

*Prepare a 1mol/L solution of Na2SiO3, 9H2O, and Ca (NO3) 2 · 4H2O;

*Take 100mL of Ca (NO3) 2 solution and pour it into a three necked flask. Add an appropriate amount of NaOH solution dropwise and adjust the solution to pH>11;

*Add 100mL of Na2SiO3 solution dropwise at a stirring speed of 1200r/min and temperature 60℃, the dropwise acceleration is 60 drops/min. After the completion of drop, the reaction lasted for 7 days.

*Wash with anhydrous ethanol, filter, and dry at 60℃ for 2 days to obtain C-S-H early strength crystal seeds.

1.3 Preparation of Low Temperature Early Strength Agent ZQ-1

A composite low-temperature early strength agent ZQ-1 was prepared using Na2SO4, NaAlO2, Li2CO3, and C-S-H early strength seeds as raw materials through orthogonal experiments. The composition of ZQ-1 is 2% Na2SO4+0.2% NaAlO2+4% Li2CO3+2% C-S-H early strength crystal seeds.

1.4 Preparation of Cement Slurry

Prepare the cement slurry system according to GB/T 33294-2016 "Test Methods for Deepwater Oil Well Cement", and the formula is shown in Table 1.

.png)

1.5 Compressive Strength Test

Pour the cement slurry into a 50x50x50mm cube cement testing mold; Make 3 parallel samples for each experimental group; Place the Samples in a low-temperature curing box and conduct compressive strength tests after 8, 12, 24, and 36 hours of curing.

2. Results and Discussion

2.1 Characterization of C-S-H Early Strength Crystal Seeds

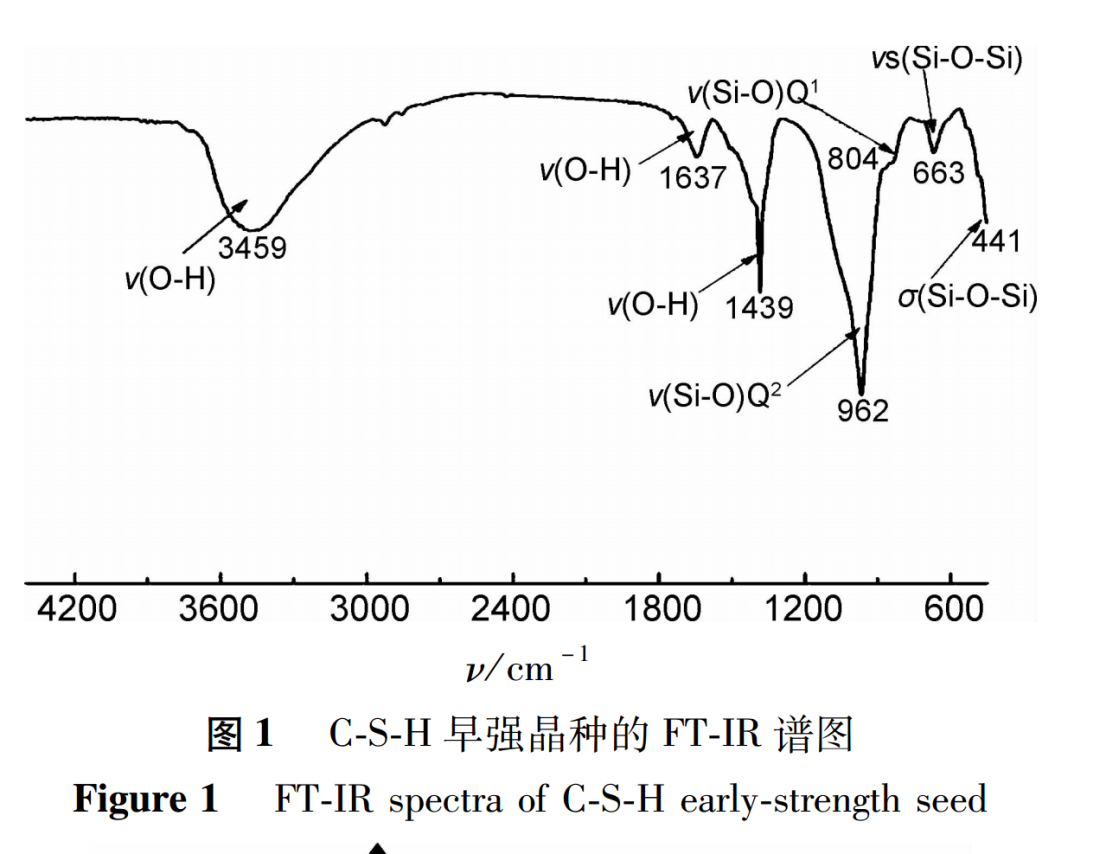

(1)FT-IR

Figure 1 shows the FT-IR spectrum of C-S-H early strength crystal seeds. From Figure 1, it can be seen that the characteristic peaks at 400-1000cm-1 are asymmetric and symmetric Si-O bond absorption peaks, while the characteristic peaks at 441cm-1 and 663cm-1 are bending vibration absorption peaks of Si-O-Si; The characteristic peaks of (Si-O) Q1 and (Si-O) Q2 in the C-S-H early strength seed structure are located at 804cm-1 and 962cm-1, indicating that the silicon oxygen tetrahedron in the synthesized C-S-H early strength seed structure is mainly Q1 and Q2, and the silicon oxygen tetrahedron in the synthesized C-S-H gel is mainly long chain; The characteristic peaks at 1637cm-1 and 3000-3700cm-1 are the stretching vibration absorption peaks of hydroxyl groups.

(2)XRD

Figure 2 shows the XRD spectrum of C-S-H early strength crystal seeds. From Figure 2, it can be seen that the diffraction peaks of C-S-H early strength crystal seeds exhibit strong and sharp diffraction peaks and low intensity diffraction peaks near 30°, while the rest are relatively dispersed characteristic peaks. The low angle diffraction peak is the layered structure diffraction peak of C-S-H early strength crystal seeds, indicating that the synthesized C-S-H crystal seeds have a certain degree of orderliness. Compared with the standard spectrum, C-S-H is mainly a gel structure, and no obvious diffraction peak of the reactant is found in the spectrum, so the purity of C-S-H gel is high.

.png)

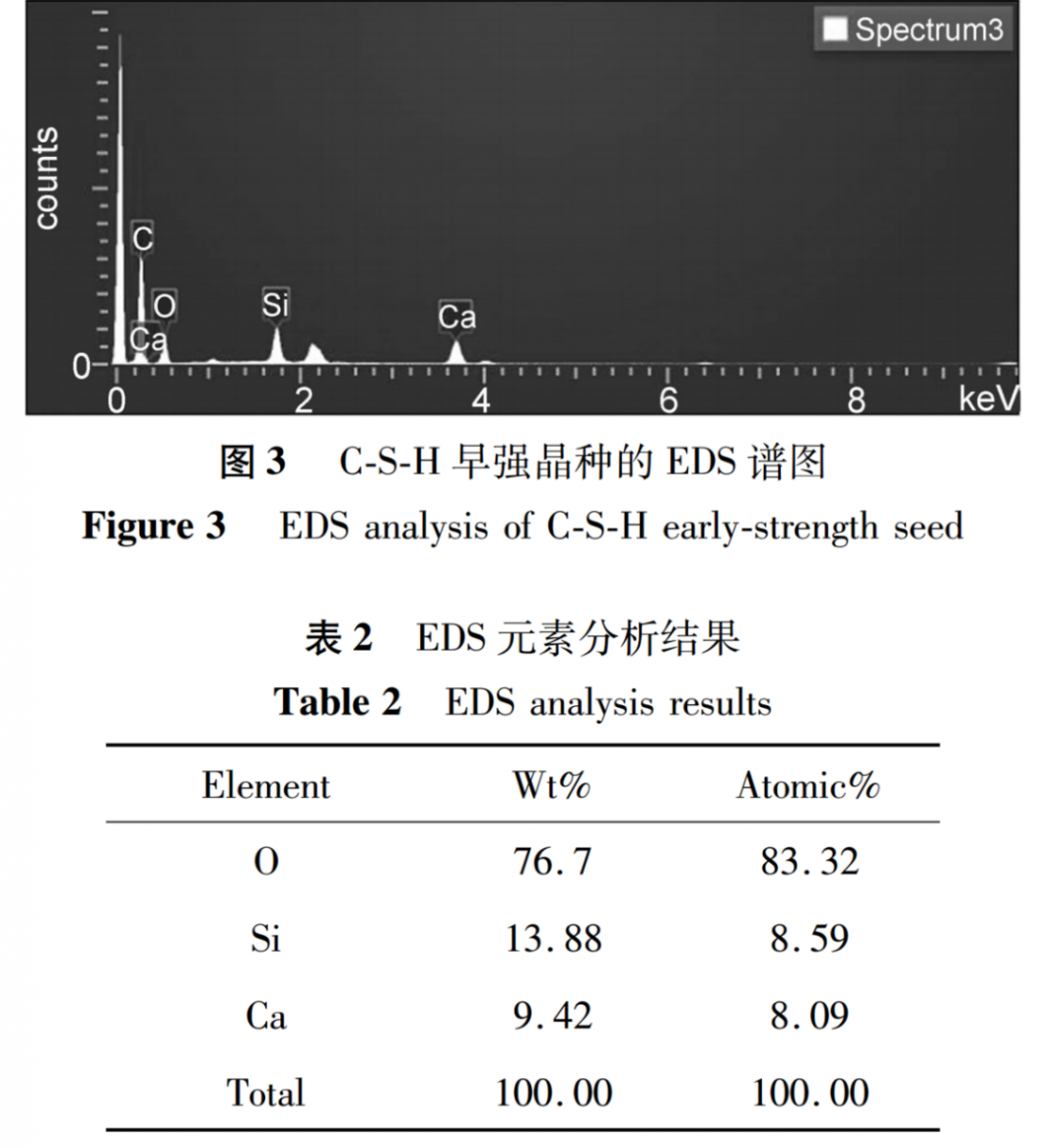

(3)EDS

Figure 3 and Table 2 show the EDS spectra and elemental analysis results of C-S-H early strength crystal seeds. From Figure 3 and Table 2, it can be seen that the early strength crystal seeds of C-S-H include calcium, silicon, and oxygen elements; The Si content is 8.59%, and the Ca content is 8.09%, so Ca/Si=8.09%/8.59% ≈ 0.94.

(4)SEM

The SEM photos of C-S-H early strength crystal seeds are shown in Figure 4. As can be seen from Figure 4, C-S-H early strength crystal seeds are mostly agglomerated, amorphous, and irregular gelled structures. In the microscopic morphology, they are stacked in layers. The stacked structure is relatively dense, and the surface is attached with irregular aggregate particles; The surface of C-S-H early strength crystal seeds is rough, with uneven protrusions and a large specific surface area, which is conducive to the nucleation of C-S-H early strength crystal seeds.

.png)

2.2 Low Temperature Enhancement Performance

Table 3 shows the compressive strength of cement stone under different dosage of ZQ-1 at a curing time of 8-36 hours and a curing temperature of 5℃. From Table 3, it can be seen that with the increase of the dosage of early strength agent ZQ-1, the compressive strength of cement paste at 8h, 12h, 24h, and 36h is improved compared to that of blank cement paste. When the dosage of ZQ-1 is 5%, the compressive strength of cement stone reaches its maximum at each curing age, with values of 0.6, 0.8, 1.4, and 2.4 MPa, respectively.

.png)