Case Studies

Case Studies

- Study on the Synthesis and Performance of a Large Temperature Difference Retarder for Oil Well Cement(Part 2)

- Study on the Synthesis and Performance of a Large Temperature Difference Retarder for Oil Well Cement(Part 1)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 1)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 2)

- Current Status and Development Trends of Key Technologies for Intelligent Oilfield (Part 3)

- New Developments in Oil Drilling Industry Technology

- Research and Application for the Fine Identification Method of Lost Circulation Characteristics During Drilling (Part 2)

- Research and Application for the Fine Identification Method of Lost Circulation Characteristics During Drilling (Part 1)

- Analysis of the Development Status and Trends of Unconventional Oil and Gas Cementing Materials (Part 1)

- Analysis of the Development Status and Trends of Unconventional Oil and Gas Cementing Materials (Part 2)

.jpg)

Drag reduction has always been an important research direction in the field of fluid mechanics. For oil and gas transportation, how to consume less energy to achieve an efficient transportation environment is one of the hot topics studied by many scholars. As early as the 19th century, people observed that rivers carrying a small amount of sediment had a greater flow rate than clearer rivers; The frictional resistance of ships and other vessels traveling to waters with algae significantly decreases; Many aquatic organisms, such as clownfish and catfish, have sticky substances attached to their epidermis. However, due to the fact that disciplines such as fluid mechanics and rheology were not yet established at that time, such phenomena did not receive sufficient attention.

1. The Discovery of the Toms Effect

Later, through extensive experimental research, it was found that adding a small amount of drag reducing additives to the fluid pipeline can achieve a drag reduction effect of 60% to 80%, which is known as the turbulent drag reduction effect. It was first discovered by Toms in 1947 when observing the mechanical degradation of flowing polymers in pipes, hence it is also known as the Toms effect. In 1948, Toms published his first paper on drag reduction phenomena at the First International Rheology Conference, in which he elaborated on his discovery that adding a small amount of polymethyl methacrylate to chlorobenzene can significantly reduce the turbulent pressure in straight pipes.

2. The Mechanism of Action of Drag Reducing Agents

The drag reduction mechanism of drag reducing agents is relatively complex, and its basic idea is to minimize the burst of turbulence, that is, to reduce the frequency and intensity of turbulence burst. Since the 1950s, extensive research has been conducted on the drag reduction mechanism of drag reducing agents, proposing effective slip hypothesis, turbulence intensity suppression hypothesis, turbulence pulsation decoupling hypothesis, viscoelasticity hypothesis, etc. Let's take a look at the main content of these hypotheses:

2.1 Hypothesis of Turbulence Intensity Suppression

We know that the flow patterns of fluids in pipelines can be divided into turbulent and laminar flow. When the fluid flow rate is high, it is easy to form turbulence and generate a large number of vortices. Due to the momentum transfer between turbulent vortices and the pipe wall, as well as the momentum transfer between vortices of different sizes, energy consumption is caused, which is the cause of fluid resistance. This hypothesis suggests that the addition of drag reducing agents significantly suppresses the generation of turbulent vortices, thereby reducing the absolute turbulence intensity, especially the radial pulsation intensity, then reducing the friction factor of turbulent flow and achieving drag reduction. However, there is no eddy current energy dissipation in laminar flow, so drag reducing agents cannot work in laminar flow.

This hypothesis can explain the characteristics of turbulent drag reduction flow and has been validated by numerous experiments, but it cannot explain the phenomenon that the turbulent structure is also altered during the drag reduction process.

2.2 Effective Slip Hypothesis

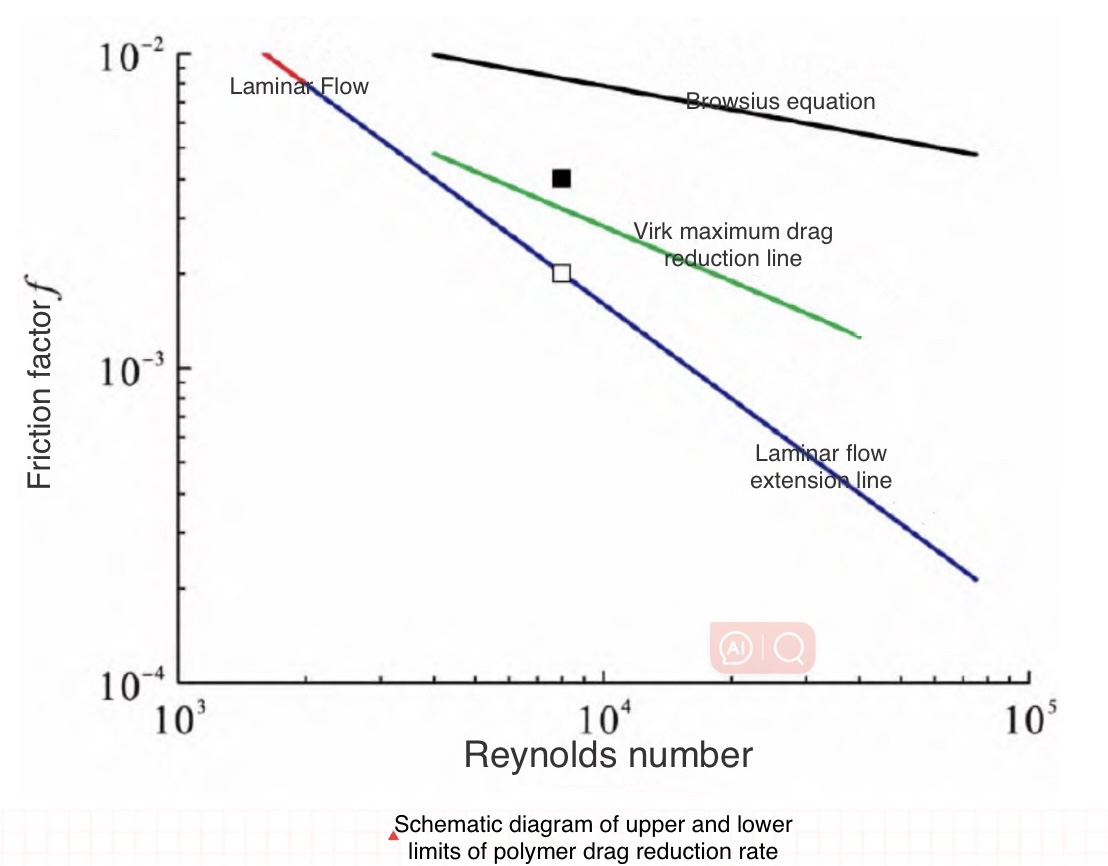

In 1967, Virk et al. conducted extensive experiments to study the effect of fluid velocity on drag reduction, and ultimately proposed the famous Virk asymptote (also known as the maximum drag reduction asymptote or MDR). The Virk asymptote is essentially the boundary between the laminar flow region of non Newtonian fluids and the turbulent flow region of non Newtonian fluids. This hypothesis was proposed by Virk, and its main content is that after adding high polymers to the fluid, an elastic buffer layer will appear between the viscous bottom layer and the turbulent core region, and the velocity curve of the turbulent core region will move upward, indicating an increase in flow velocity and a relative increase in flow rate. When the elastic buffer layer is extended to the flow center, the optimal drag reduction effect is achieved. But it cannot explain the concentration effect of drag reducing agents, that is, why the resistance increases when the concentration of drag reducing agents exceeds a certain value.

2.3 Viscoelastic Hypothesis

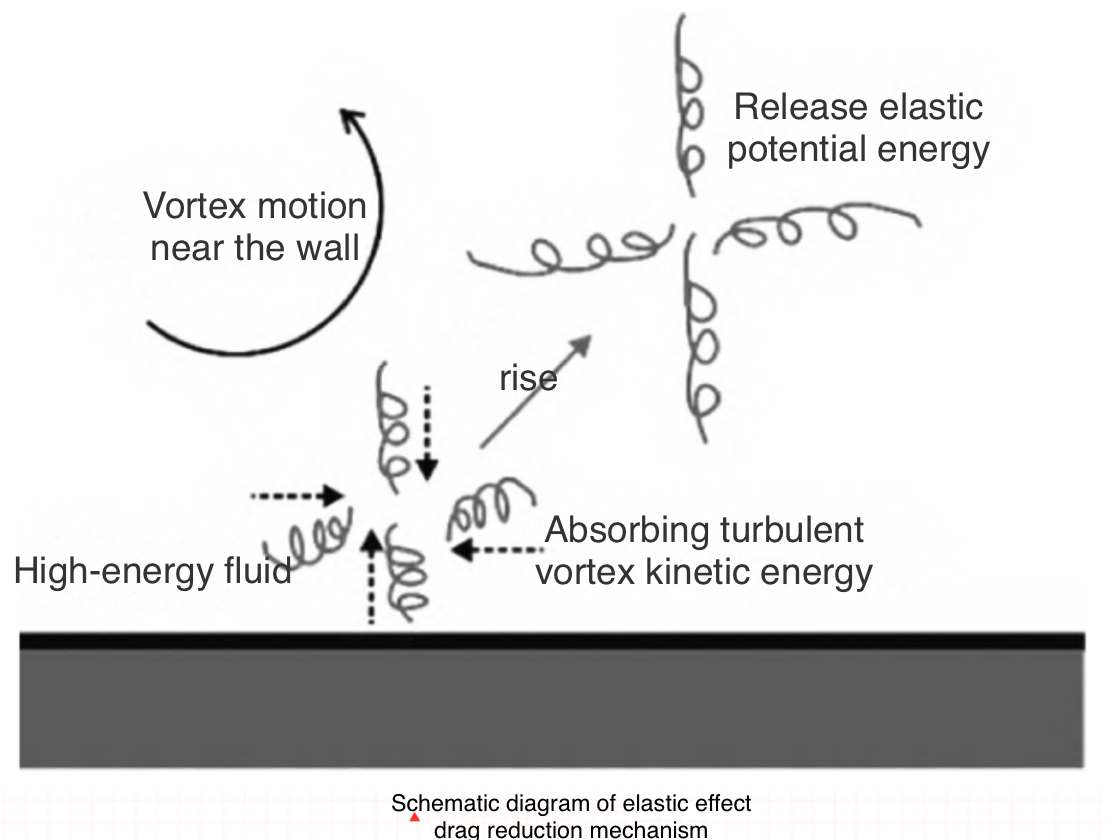

The polymers in drag reducing agents are linear polymer solutions with viscoelasticity. These polymer solutions interact with turbulent vortices, absorbing some of the eddy energy and storing it in the form of elastic properties, reducing eddy energy dissipation. The drag reducing agent forms an elastic bottom layer inside the pipeline, reducing the friction between the fluid and the pipe wall, and achieving the effect of drag reduction.

3. The Application Value of the Toms Effect

People attach great importance to the research of polymer drag reduction, firstly because this technology has great economic value and has two significant characteristics: firstly, it has low investment; The second is that the drag reduction effect is very significant. So it has broad application prospects in fields such as national defense, industry, transportation, and fire protection, especially in long-distance pipeline transportation of fluids. The application of this technology will greatly increase transportation volume or save energy consumption during transportation.

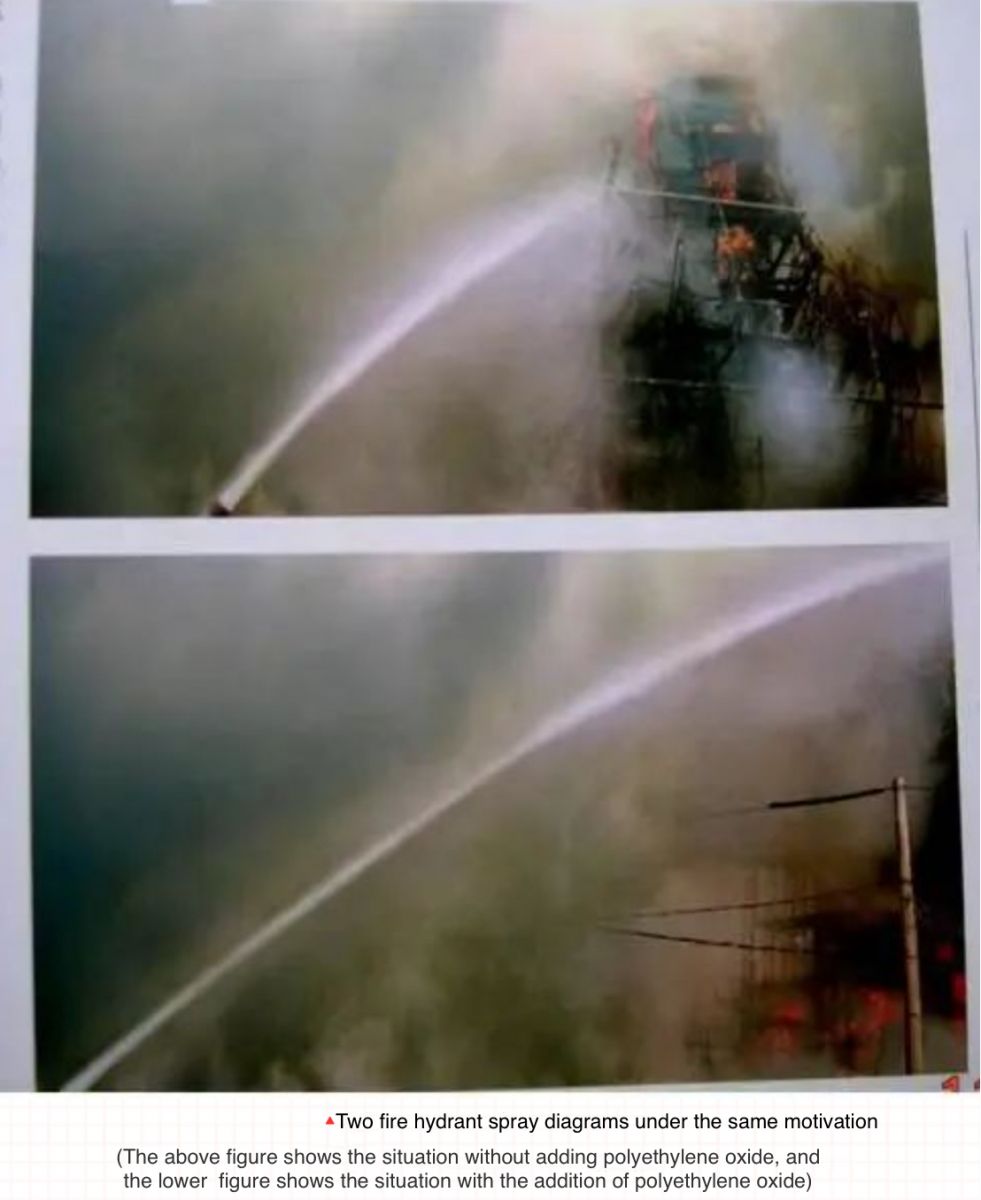

Polymer additives for drag reduction have been widely used in many fields due to their convenience in implementation. For example, adding a small amount of polyethylene oxide to fire water can increase the head of water sprayed from the fire truck faucet by more than double; In medicine, it can be used to reduce the viscous friction of blood flow, increase blood flow, and treat coronary heart disease; In terms of crude oil transportation, this method can reduce the intermediate pumping stations of long transportation pipelines, save energy and equipment, increase flow rate, and shorten the berthing time of ships in the port.