Our Products

Многофункциональная Добавка Потери Жидкости

Summary

ZOC-511L is a polymer oil well cement Fluid Loss Additive,the good AMPS with temperature and salt resistance is the main monomer,combined with other salt-resistant monomer copolymerization,the molecule contains a large amount of -CONH2, -SO3H, -COOH and other highly adsorbable groups,for anti-salt, anti-temperature, adsorption of free water, loss of water plays an important role.

ZOC-511L has a good versatility, can be used for a variety of cement slurry system, and other additives with good compatibility.

ZOC-511L suitable for wide temperature,Anti-high temperature of 150 ℃, cement slurry system is good mobility, stability, free liquid less, not retarded, the strength of the development of fast, can be directly with seawater with pulp, with no special requirements for pulp and water quality.

Fluid Loss Additive include ZOC-511L (standard) and ZOC-511L -W (antifreeze)

Usage range

Temperature:150 ° C (BHCT) or less

Recommend dosage:3.0%-5.0%(BWOC)

Technical Index of the product

|

Items |

Index |

|

|

Model |

ZOC-511L (standard) |

ZOC-511L -W (antifreeze) |

|

Appearance |

Colorless or yellowish viscous liquid |

Colorless or yellowish viscous liquid |

|

Density, g/cm3 |

1.05±0.05 |

1.10±0.05 |

|

Freezing point ,℃ |

-5 |

-15 |

Cement slurry property

|

Items |

Technical index |

Test condition |

|

Water loss, ml |

≤50 |

80℃,6.9MPa |

|

Thickening time, min |

≥60 |

80℃,45MPa/45min |

|

Initial consistency, Bc |

≤25 |

|

|

compression strength ,Mpa |

≥14 |

80℃, Atmospheric pressure ,24h |

|

Free water, ml |

≤1.0 |

80℃, Atmospheric pressure |

|

Cement slurry composition:100% grade G cement (high sulfur resistance)+44% mixed water (sea water)+4.0%ZOC-511L+0.5% ZOC-X60L |

||

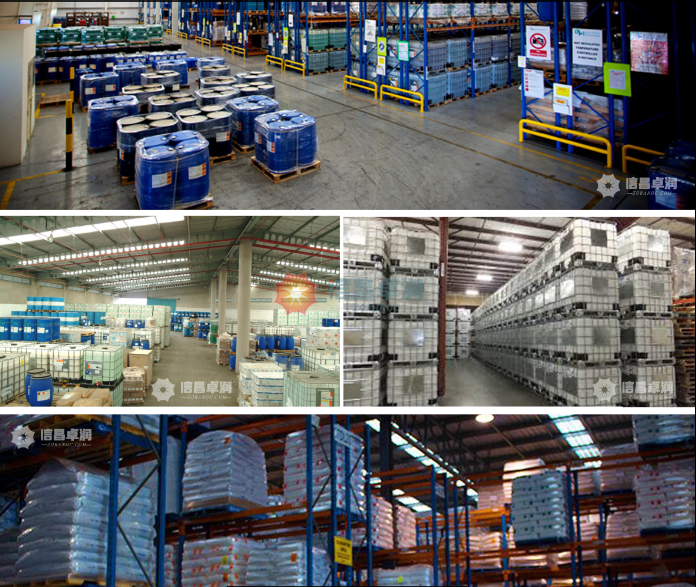

ZOC-511L with 200L plastic drums,or according to customer requirements for packaging.